Home » Fire Pump Set » 2500gpm@10bar EDJ Fire Pump Set Test

2500gpm@10bar EDJ Fire Pump Set Test

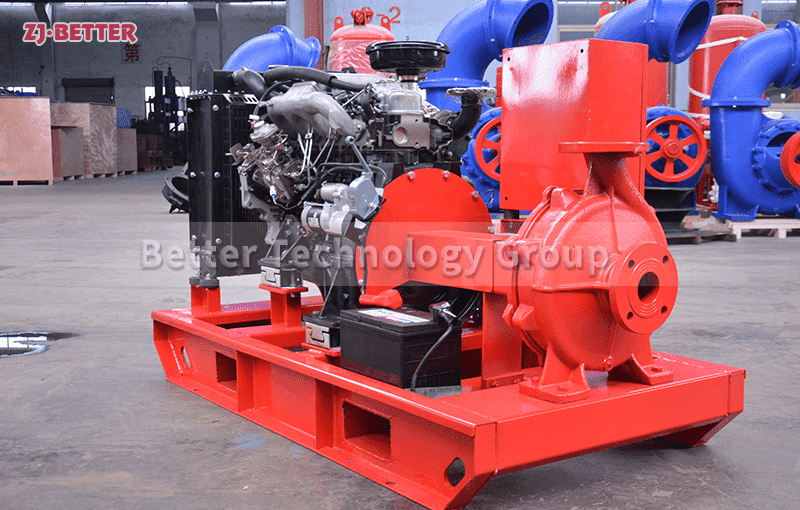

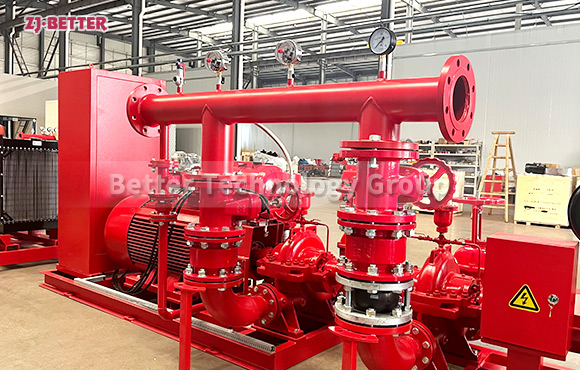

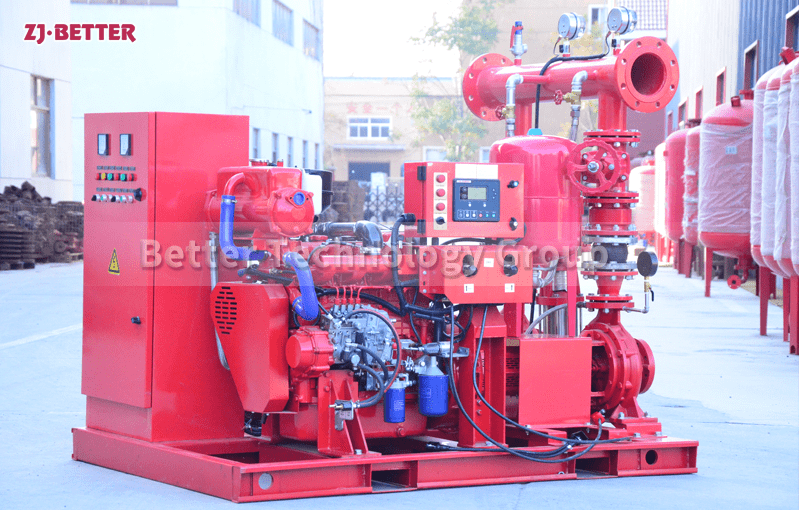

Flow: 2500gpm

Head: 10bar

This pump uses horizontal split case pump.

We manufacture in strict accordance with customer requirements. All products will be tested before leaving the factory to ensure that there are no problems. The design meets the national standard of general packaging, meets customer needs, and standard handling and transportation.

Contact US

Get Price

Share:

Previous:

100gpm@17bar EEJ Fire Pump Set Test

Content

Flow: 2500gpm

Head: 10bar

This pump uses horizontal split case pump.

We manufacture in strict accordance with customer requirements. All products will be tested before leaving the factory to ensure that there are no problems. The design meets the national standard of general packaging, meets customer needs, and standard handling and transportation.

Inquiry

More Fire Pump Set