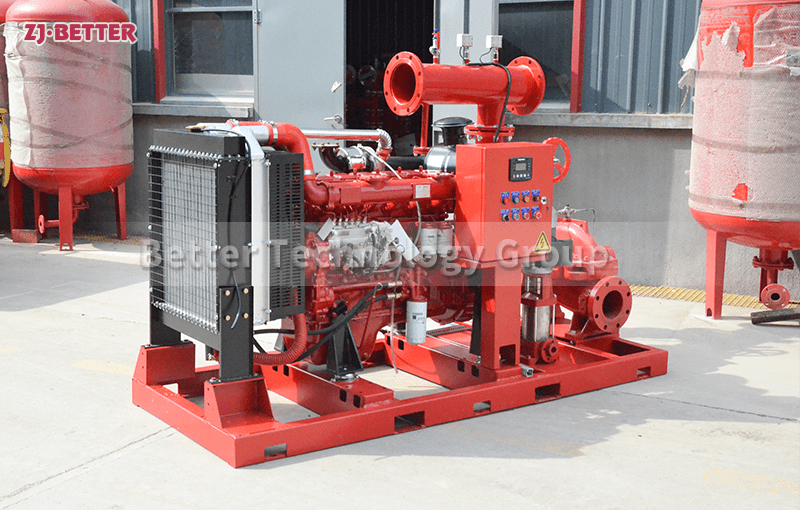

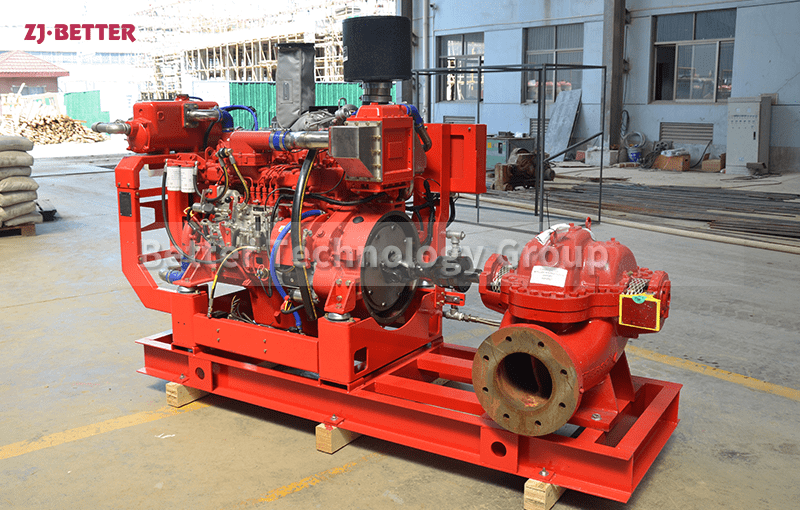

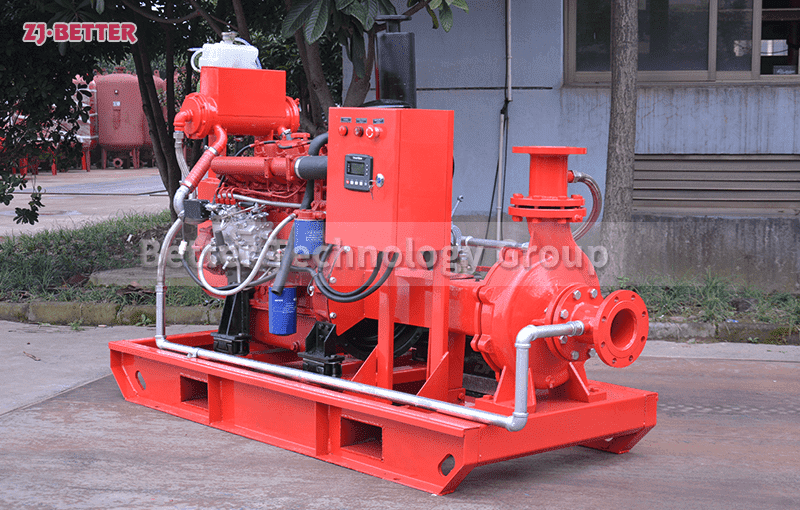

325KW XBC-OTS Fire Pump

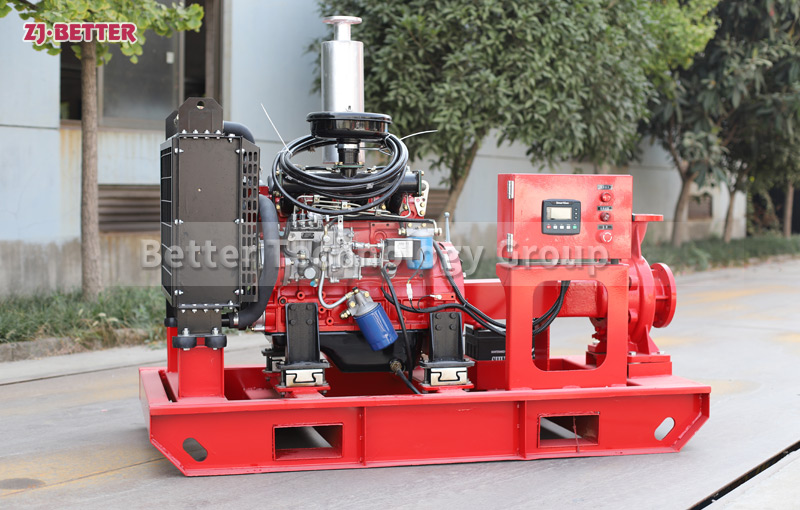

1. When a fire occurs, the power supply fails and the electric fire pump unit cannot be put into use normally, the diesel engine fire pump unit can be automatically put into operation to ensure the normal firefighting.

2. There is no need for long-term investment in power resources, saving commercial power supply transformers and normal expenses.

The diesel engine fire pump set is equipped with various automatic functions to meet the requirements of national standards and ensure the equipment is in a normal standby state for a long time, and can be put into fire fighting work at any time.

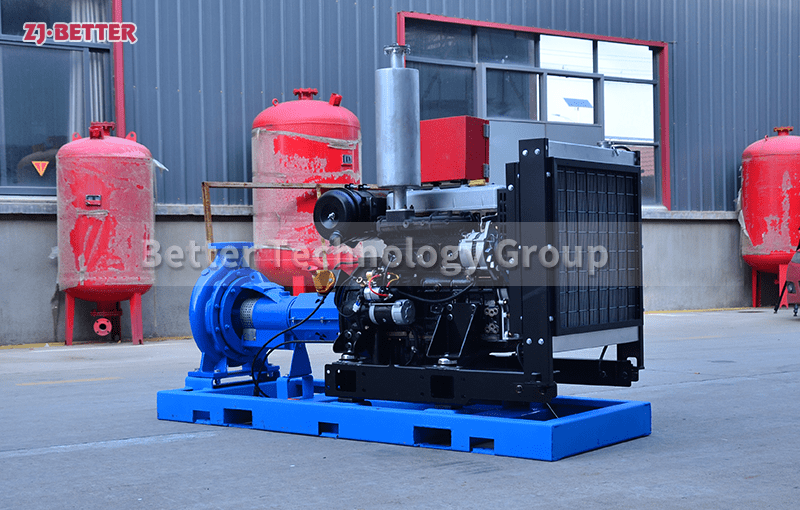

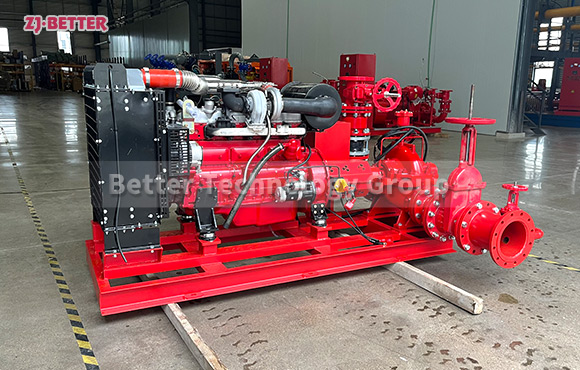

Series OTS pumps are single stage,double suction with horizontally split casings .They are suitable pumping unsettled water, clean water ,non-drinkable or hydrocarbon at a temperature not exceeded 105C.

Series OTS pumps are available for capacities Of 68-18000m3/hr and heads of 70-200m.They are adoptable in water works irrigation and drainage pumping stations,fire fighting systems, marine applications as well as refinery industry,etc.

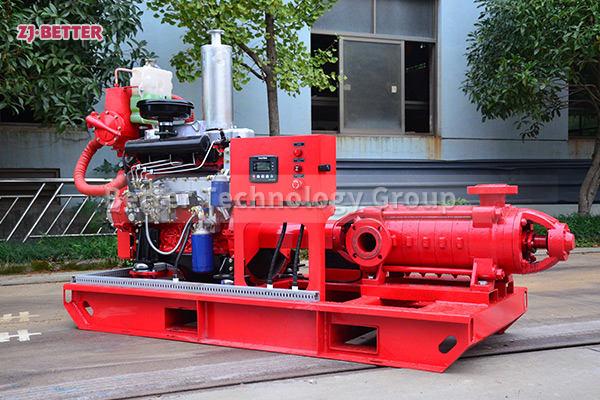

FEATURES

Split case design permits easy dis-assembly, that is, inspection is simplified, it is not necessary to disturb pump alignment and suction & discharge piping when parts replacement is necessary. Double suction with advanced design of suction performance ensures high suction lift even with large capacity. Pump operation with low noise and stability, in use ensure comfortable environment. Variable combination of materials permit wide application. Drive shaft end of the pump optionally on the left or right. Shaft seal uncooled soft- packed stuffing box or uncooled single acting unbalanced mechanical seal, etc.