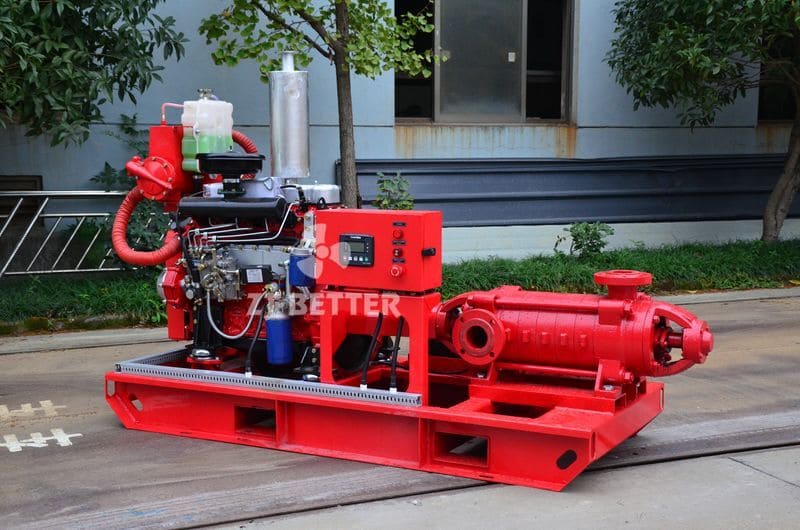

372KW Diesel Multistage Pump

The multistage pump has the advantages of high efficiency, reliability, durability, low noise, convenient maintenance and wide application range. D series single-suction multistage centrifugal pumps are widely used in high-rise buildings, fire protection, boiler feed water, high-pressure cold and hot water circulation of cooling water systems, parallel booster pump water supply systems and various irrigation fluid transportation. It is used to transport water or similar physical and chemical liquids with no solid particles and a temperature below 80 °C. Our factory’s products are all tested before leaving the factory to ensure that there are no quality problems.

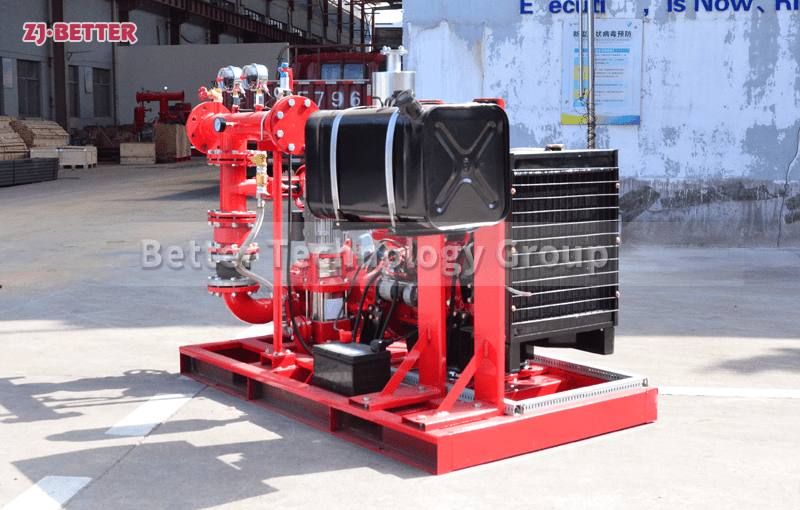

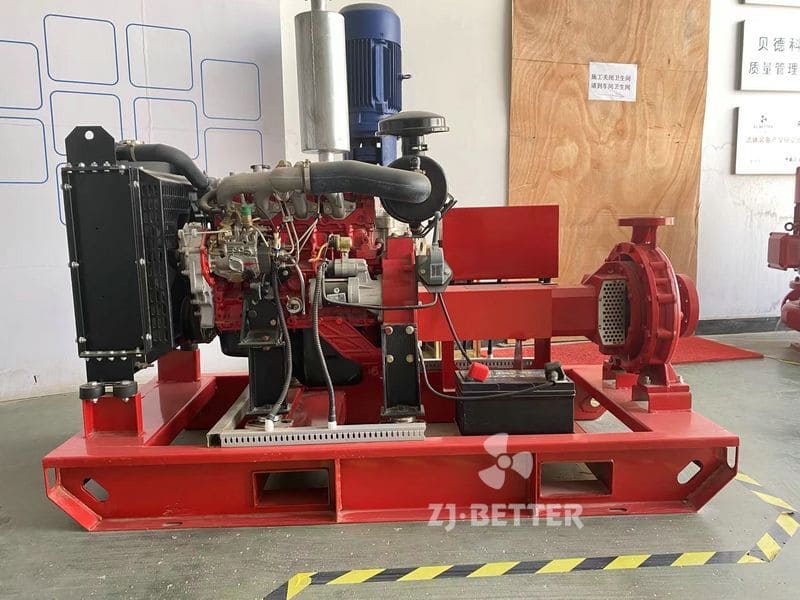

XBC series diesel engine fire-fighting pump group is a new-style fire-fighting equipment developed in accordance with GB6245-98 and NEPA20 standard, and upon the fitted fire-fighting pumps (single-stage single-suction type, single-stage double-suction type and sectional multistage type), can be divided into XBC-IS, XBC-S and XBC-D three sub series. The equipment has a wide range of pressure and temperature and can be used for almost every occasion necessary for fire-fighting.

The diesel engine fitted with the equipment is an excellent product domestic or imported, features good starting performance, strong overload capacity, compact structure, easy maintenance and use and high degree of automation. The equipment is really a fire-fighting one advanced and reliable in performance.