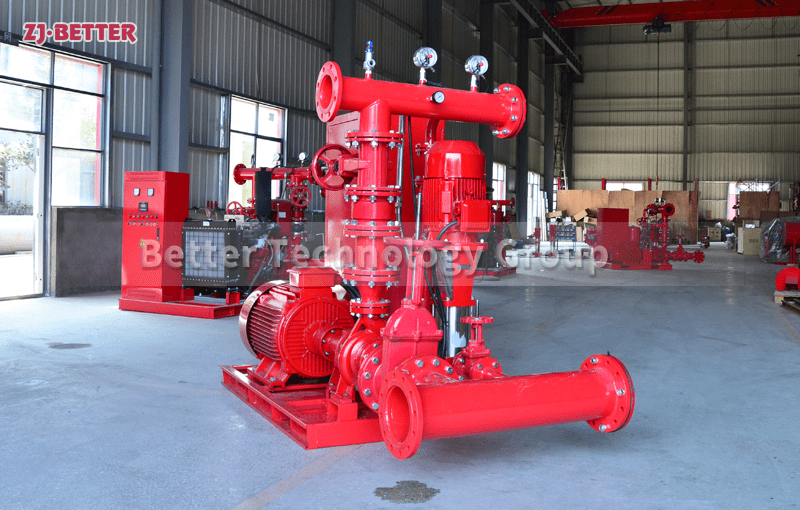

400gpm@90psi EDJ Fire Pump Set

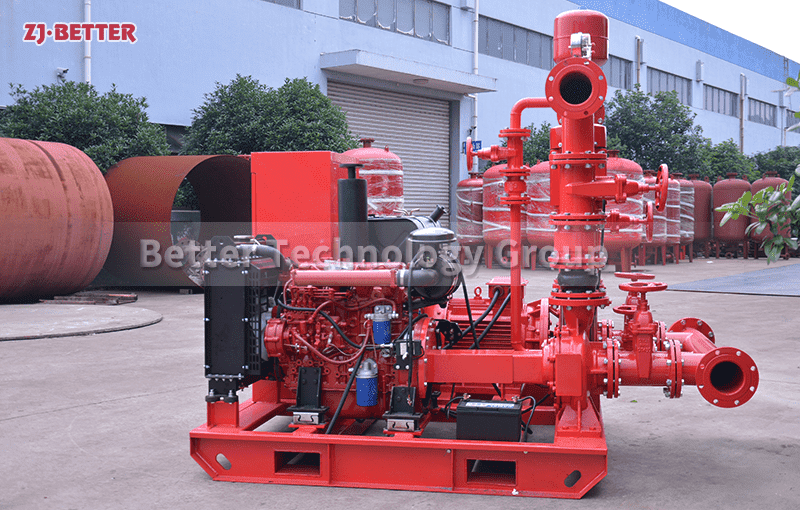

This is a set of 400gpm@90psi fire pump set, which consists of electric pump + diesel pump + jockey pump. Multiple fire pumps work together to ensure the quantity and stability of water supply. It is a pump set for fire water supply. A diesel fire pump to ensure normal operation in emergency situations.

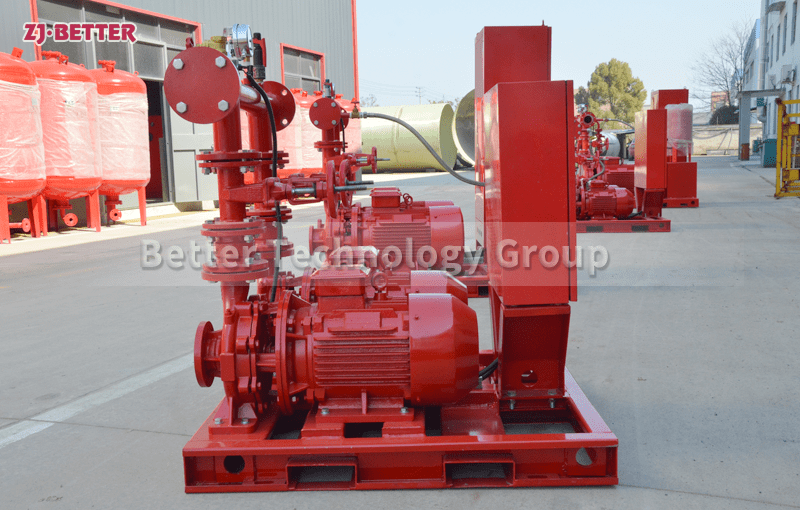

The main components of the electric motor fire pump group are the motor and the pump body. The subdivision of the pump body is the pump casing, the impeller, the pump shaft, the bearing, the coupling, the sealing form, the water lifting pipe, etc.

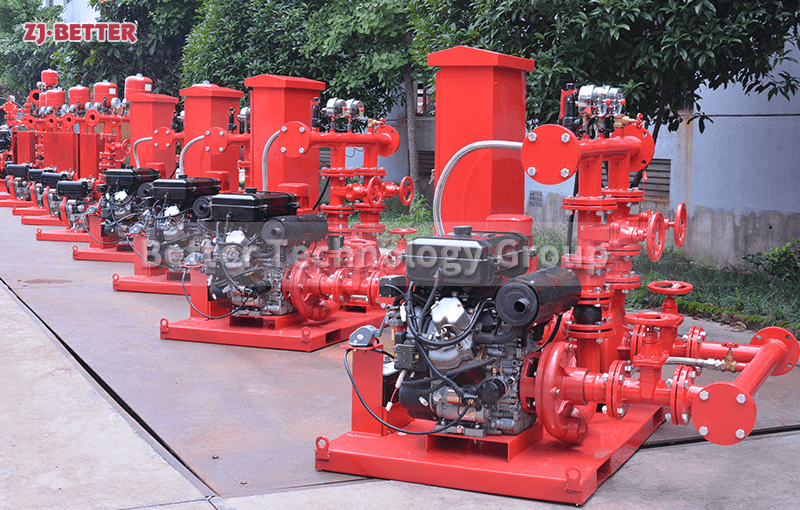

Our company has professional technicians and sales personnel, and determines the specific fire pump model according to the environment and performance requirements. At the same time, according to the material quotation required by the customer, accurate selection is conducive to on-site use and reduces failure problems. There are two kinds of sealing forms of electric motor fire pump set: packing seal and mechanical seal. Different forms can be used in different environments. For most users, the suitable fire pump selection material is a good equipment, and it does not need to exceed the required good material. and oversized models, otherwise it is easy to cause many problems such as failures and difficulties in maintenance and repair.