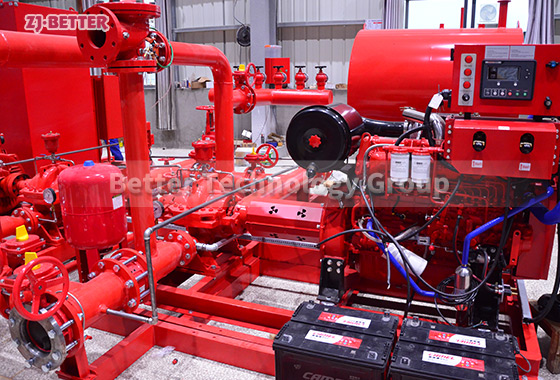

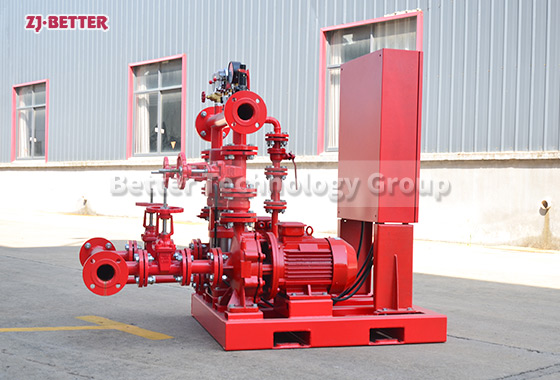

500gpm @ 130psi EJ Fire Pump Set

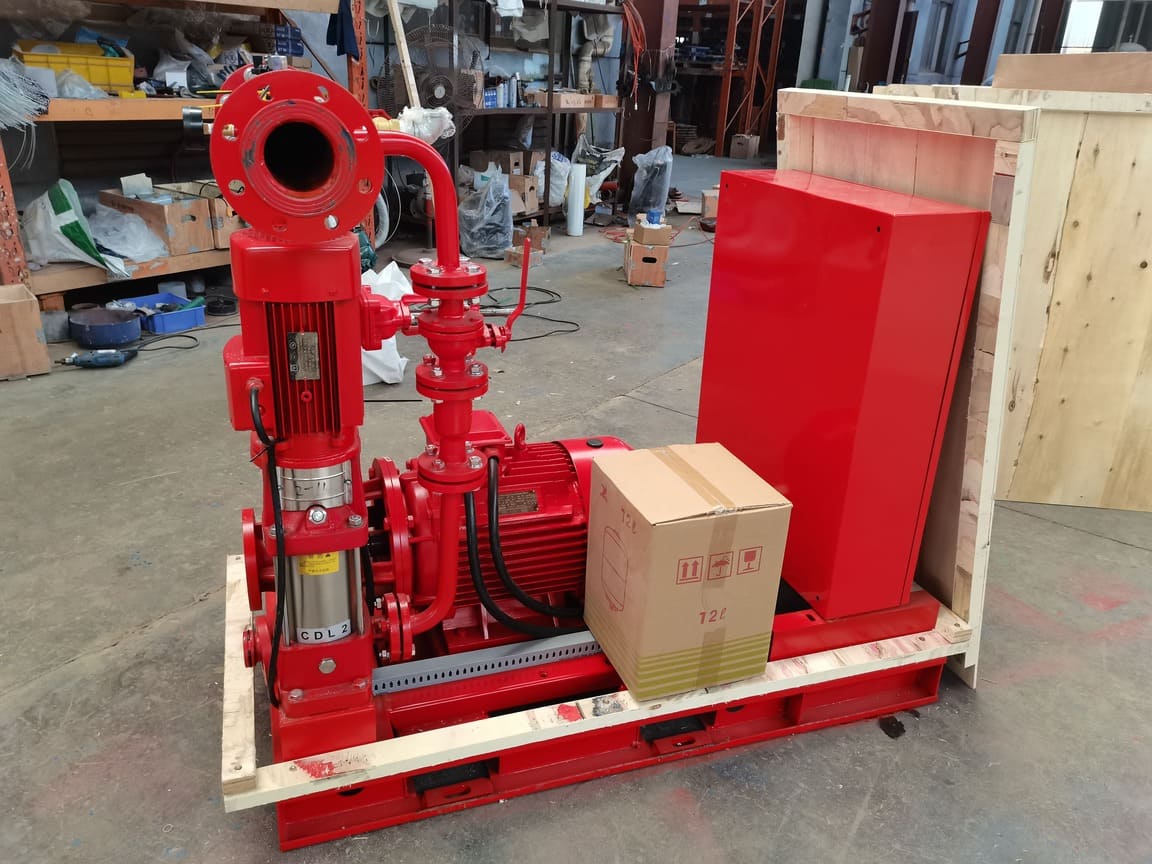

The EJ fire pump set consists of an electric pump and a jockey pump. The electric pump adopts an XA pump, and the jockey pump adopts a CDL pump. The flow rate of this pump is 500gpm and the lift is 130psi. It is manufactured in strict accordance with customer requirements. It is cast iron, the impeller of the electric pump is made of cast iron, the pressure jockey pump is made of stainless steel, and the seals of the pumps are all mechanical seals, which will not leak.

1. Electric pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller.

2. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump;

Jockey material casing :cast iron ,shaft and impeller SS304.

3. Control panel: Auto Control of electric pump, and Jockey Pump with overload, over current protection.

4. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, Pressure Gauge, Pressure Sensor, Common Pipe for Suction and Discharge, Flexible Joints and Flanges, Common Base plant.

Earthquake-resistant electrical contact pressure gauges are equipped with buffer valves at the pressure gauges and interfaces to reduce pressure fluctuations caused by false alarm signals of the pump;

Flexible Joints the material is rubber, shock absorption, noise reduction, the vibration is relatively large when the pump is started, if it is a rigid connection, it is easy to pull off, and the rubber joint can absorb the vibration generated by the pump or valve, which is convenient for pipeline connection.