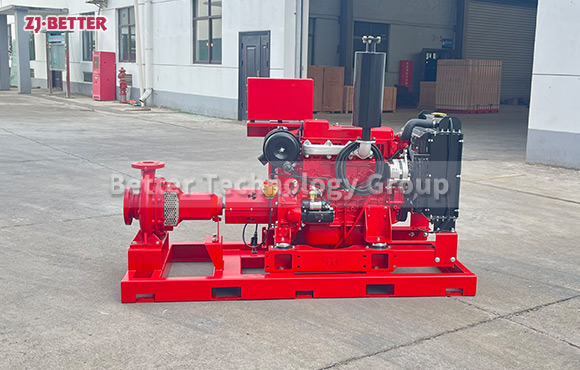

500GPM 140PSI ISO End Suction Fire Pumps for Critical Situations

Flow:500 GPM

Head:140 PSI

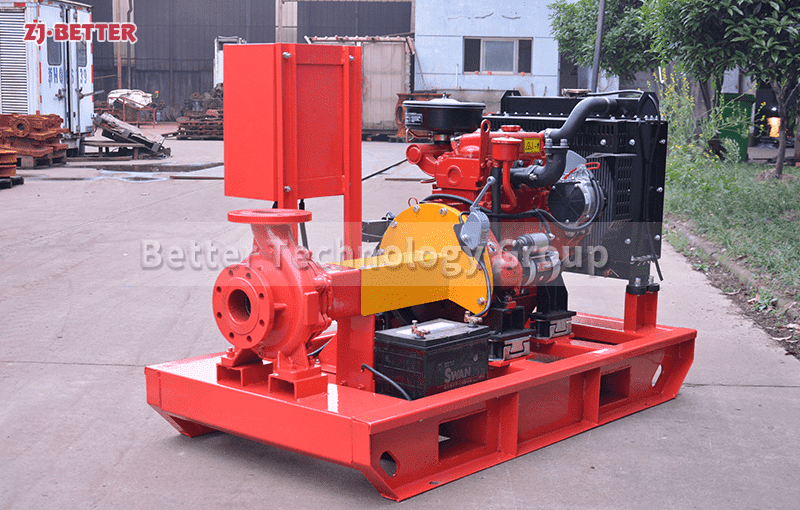

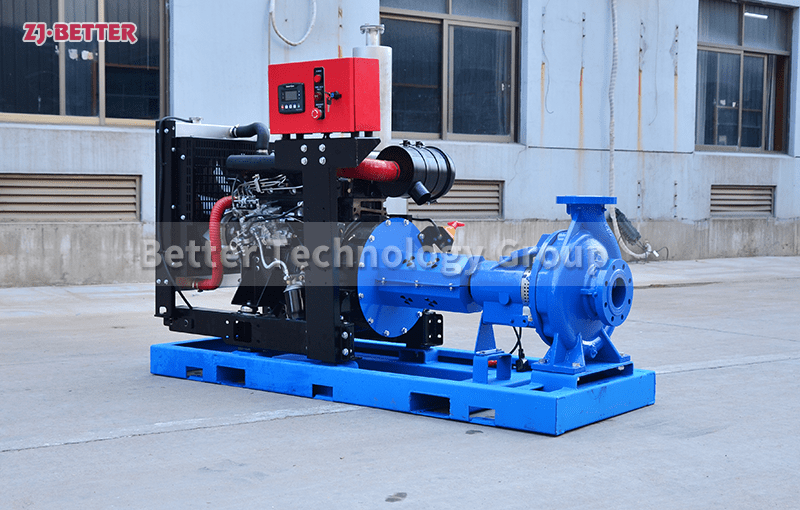

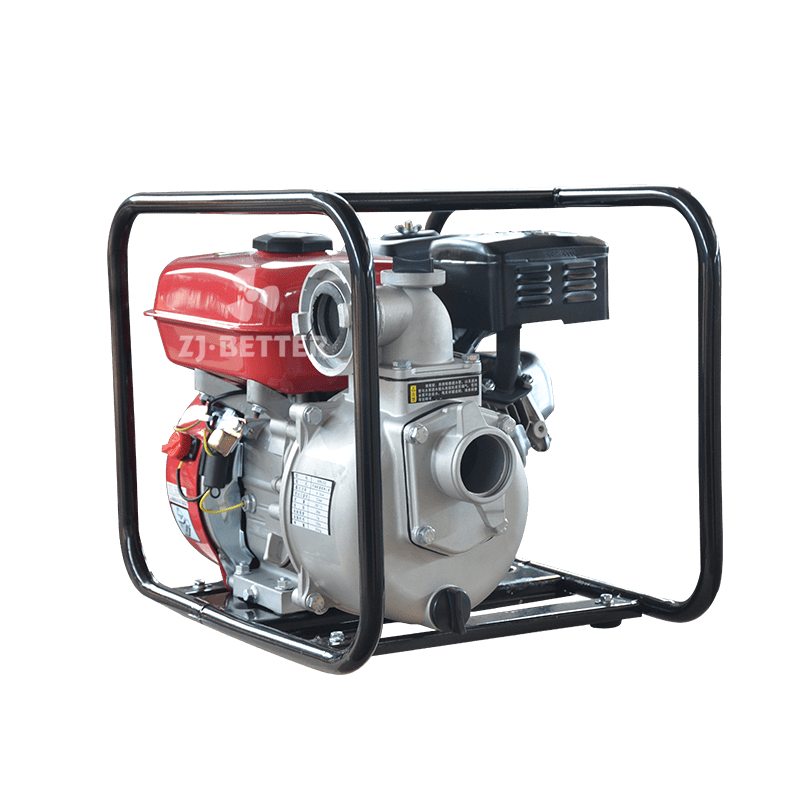

The Diesel Engine End Suction Fire Pump set is suitable for emergency firefighting scenarios, particularly ideal for high-rise water supply, building firefighting, central air conditioning water circulation, industrial process system circulation, cooling systems, boiler water supply, industrial water supply and drainage, water plant supply, irrigation in plantations, and more.

Application: Suitable for various fire booster and pressure stabilization scenarios; various villas, residential communities, and fire systems; industrial and civil building firewater systems; places with high fire protection requirements such as oil depots and docks.

Permissible Media: Potable water, chilled water, firewater, and other media without abrasive impurities or long fiber impurities that cause chemical or mechanical corrosion to the pump. The permissible maximum medium temperature is 70 degrees Celsius, and the maximum ambient temperature is 40 degrees Celsius.