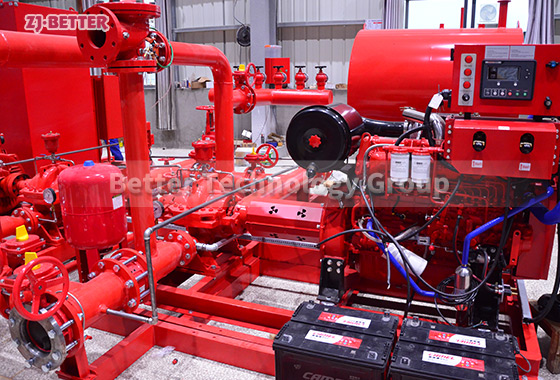

1. The switching of the main and standby pumps is a necessary condition to ensure the operation of the fire pump.

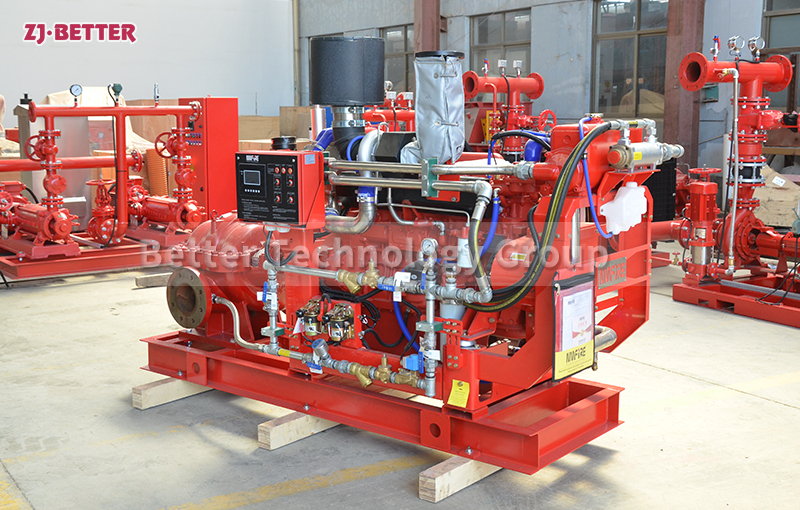

2. The fire pump is used to stabilize the pressure of the automatic sprinkler system and the fire hydrant water supply system, so that the water pressure of the system is in the required pressure state. Once the sprinkler or fire hydrant comes out of water, it can flow out the water volume and water pressure required for the fire water.

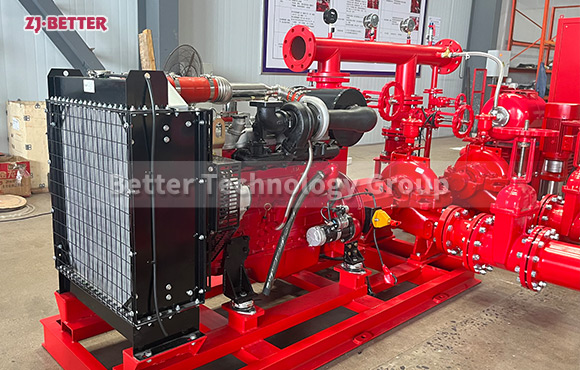

3. The fire pump is mainly used for pressurizing water supply in the pipeline of the fire fighting system. It can also be used in industrial and urban water supply and drainage, high-rise buildings and water supply, long-distance water supply, heating, bathroom, boiler cold and warm water circulation pressurized air conditioning refrigeration system water supply and equipment matching and other occasions.

The fire pump has many functions and is an essential fire fighting tool in many places. Once there is a fire, its function will come in handy. It uses the pressure to spray water to extinguish the fire in time, and the use efficiency is relatively high.