500gpm Fire pump set test

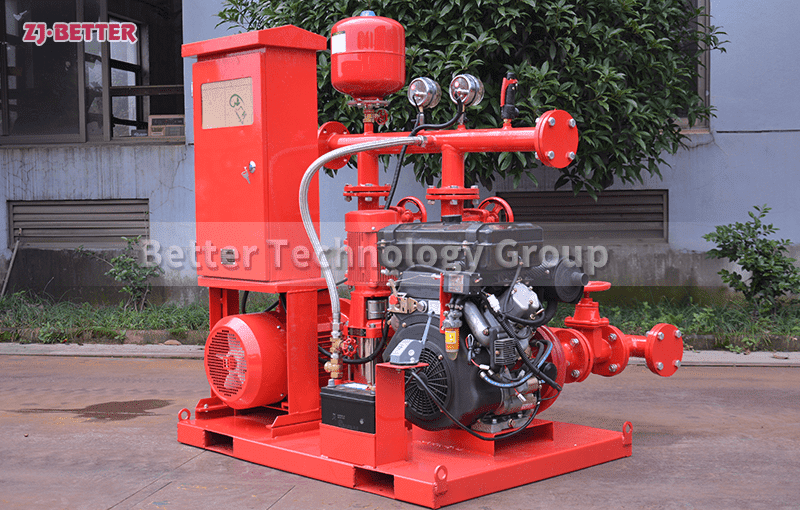

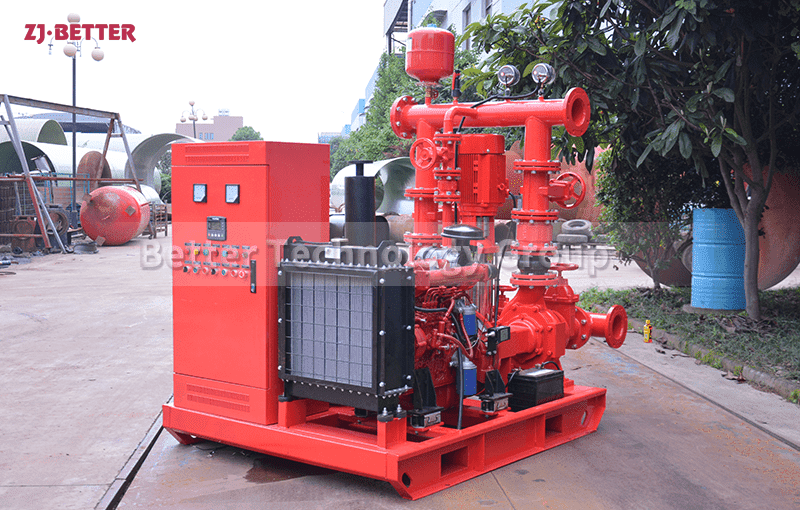

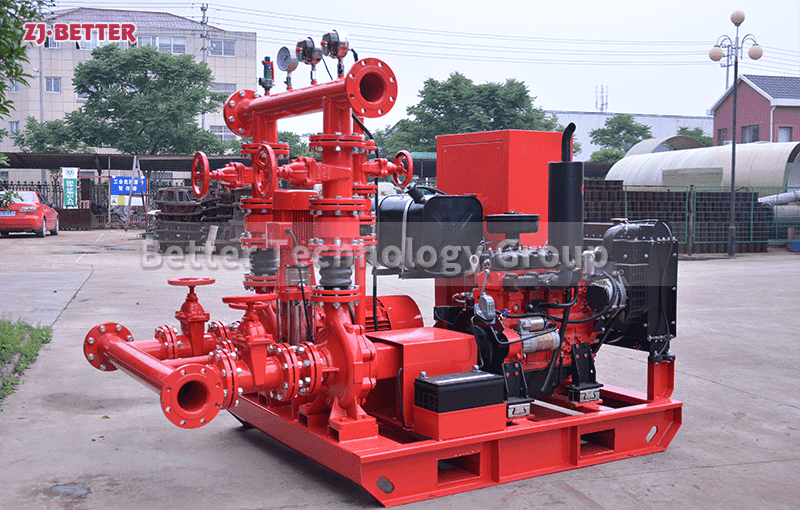

A fire pump is part of the water supply for a fire sprinkler system and is powered by electricity, diesel or steam. It uses water from an external source to increase water flow and pressure. The pump inlet is either connected to a public groundwater supply line or to a static water source. The pump provides higher pressure water flow to the sprinkler system risers and hose risers. Fire pumps must be tested monthly and annually to ensure they are operating as designed. These two different tests are called the monthly “churn” test and the annual flow test.

The fire pump flow test must be performed annually to measure the flow and pressure of the pump. The test is performed by connecting a hose to the discharge test manifold. The hose is run to a safe position where the high pressure water flow will not cause any damage. During the flow test, pressure readings are taken during each stage of pump operation, plotted on hydraulic coordinate paper, and compared to factory specifications and test results from previous years. If the pump performance is significantly degraded, further inspection is required to make any necessary repairs.