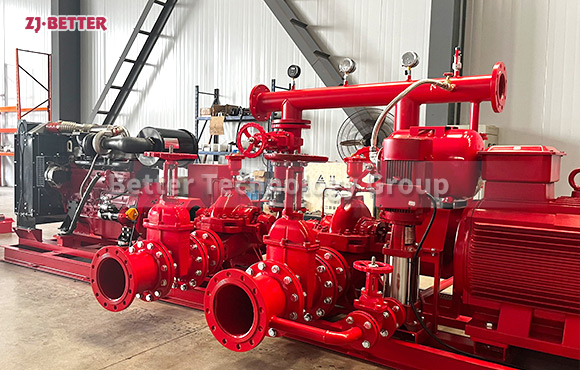

70m3/h@60m Fire pump set test

70m3/h@60m Fire pump set test

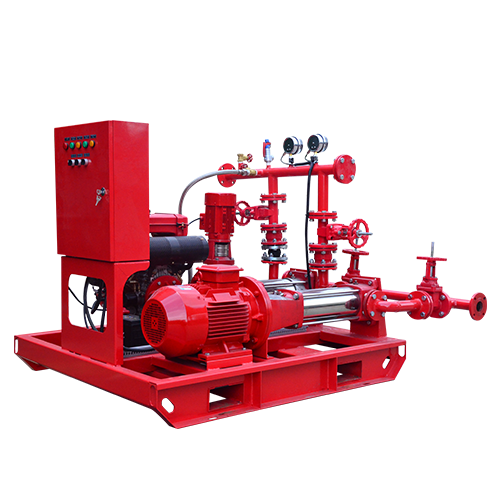

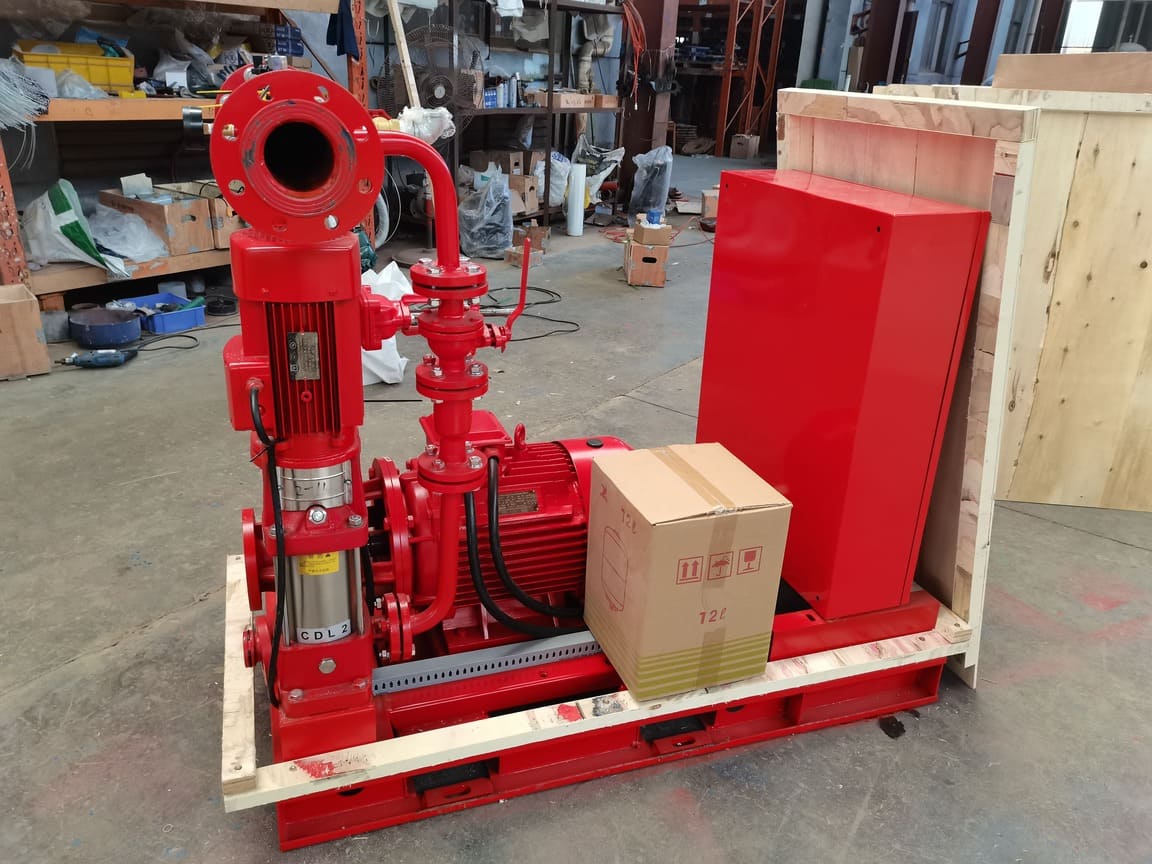

We manufacture in strict accordance with customer requirements. All products will be tested before leaving the factory to ensure that there are no problems. The design meets the national standard of general packaging, meets customer needs, and standard handling and transportation.

Test contents of fire pump products:

1.Flow:The flow of the fire pump determines the amount of water that can be discharged from the pump per second or per hour, which is the most critical in the use of the fire pump. It is assumed that if a fire occurs and the purchased pump cannot provide a large amount of water, the fire momentum will expand and the consequences will be unimaginable.

2.head:The head determines the distance that the fire pump can transport the liquid, which depends on the distance from the water source to the pump room and the required transport distance. Therefore, it is very important to test the head.

3Power of diesel engine and motor:

The power of diesel engine is the core part of the whole fire protection system. The power directly determines the efficiency of the pump. It needs to be tested to determine whether it meets the needs of customers.