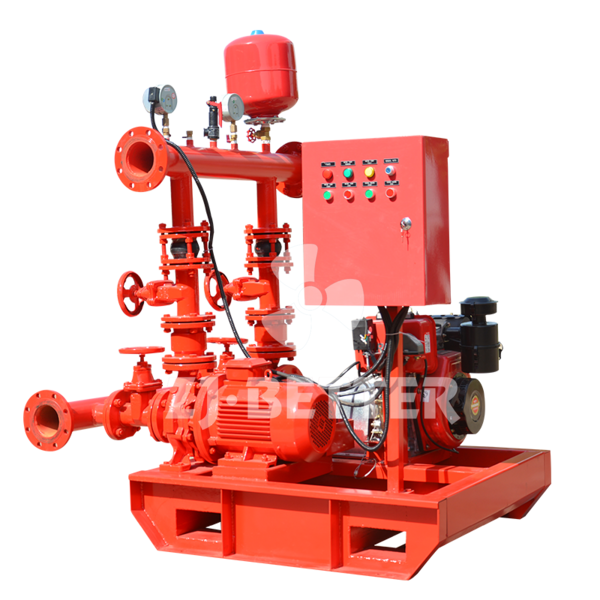

750gpm@90m EDJ-XA Fire Pump Set

The fire pump set is composed of electric pump + diesel pump + jockey pump. It is a set of 750gpm@90m pump set, which is manufactured in strict accordance with the NFPA20 standard.

The fire pump adopts XA pump, the product combines the advantages of similar products at home and abroad, and adopts the excellent hydraulic model design. Therefore, its excellent hydraulic performance and structural characteristics ensure that users can effectively reduce the operating cost of the pump in various applications. The fire pump group of this group is not affected by the mains. When the electric pump fails, the diesel pump will automatically start to operate.

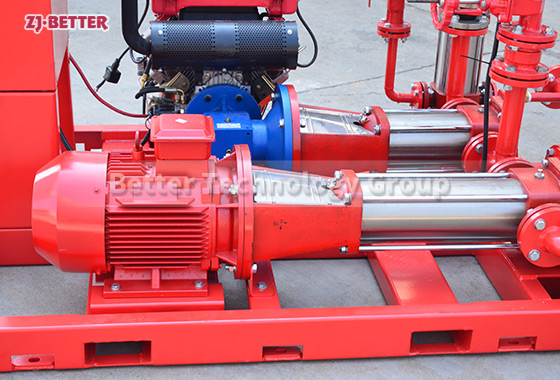

XA series single-stage centrifugal pump is the first single-stage single-suction centrifugal pump product launched by Better (China) Technology Group Co., Ltd.

Meet high standards:

XA single-stage single-suction centrifugal pumps comply with international standards: ISO9908, technical specifications for centrifugal pumps, class III (technical specifications for centrifugal pumps, class III), mainly based on German DIN standards.

Easy-to-install structural design:

1. Rear open cover design, the rotor parts can be replaced without dismantling the pipeline.

2. Replaceable sealing ring. Wear of the impeller ring can be achieved simply by replacing the seal ring, thus restoring the pump to optimum operating condition for low cost operation.