Advantages of Mobile Small Diesel Fire Pumps

Diesel engine fire pumps are very versatile and play a very important role in fire protection. Using it can also solve many problems that we could not solve before, and it has brought great help to firefighters. It saves time and effort. efficiency.

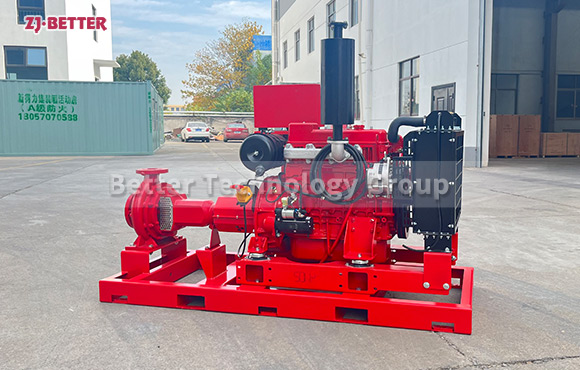

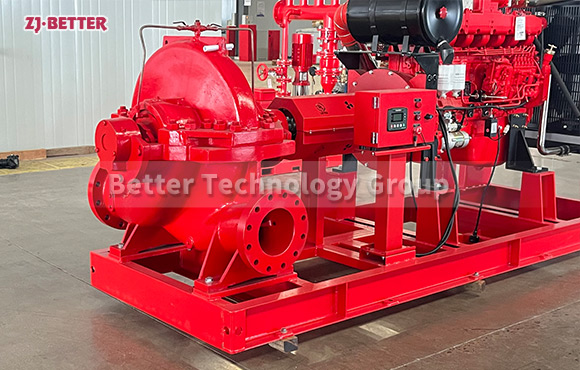

The hand-held diesel engine fire pump is compact in structure, small in size and beautiful in appearance. Its vertical structure determines that the installation area is small, and its center of gravity coincides with the center of the pump foot, thus enhancing the operation stability and service life of the pump. The pump suction and The discharge outlets are all in the horizontal direction, which simplifies the connection of the pipeline. The pump rotor has a small winding, stable operation, small vibration, low noise and long service life. Diesel engine fire pumps are mainly used for pressurized water delivery in firefighting system pipelines, and can also be applied to industrial and urban water supply and drainage, pressurized water delivery for high-rise buildings, long-distance water delivery, heating, bathrooms, boiler cold and warm water circulation pressurized air-conditioning refrigeration system water delivery and equipment support, etc. occasion.