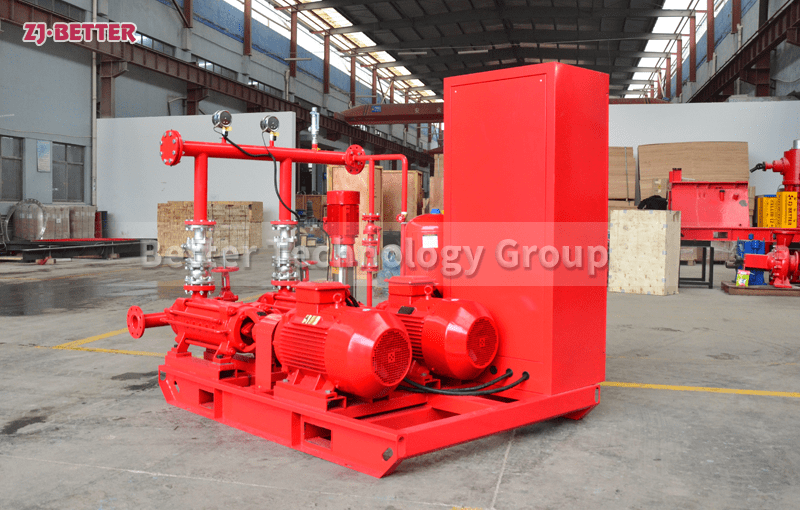

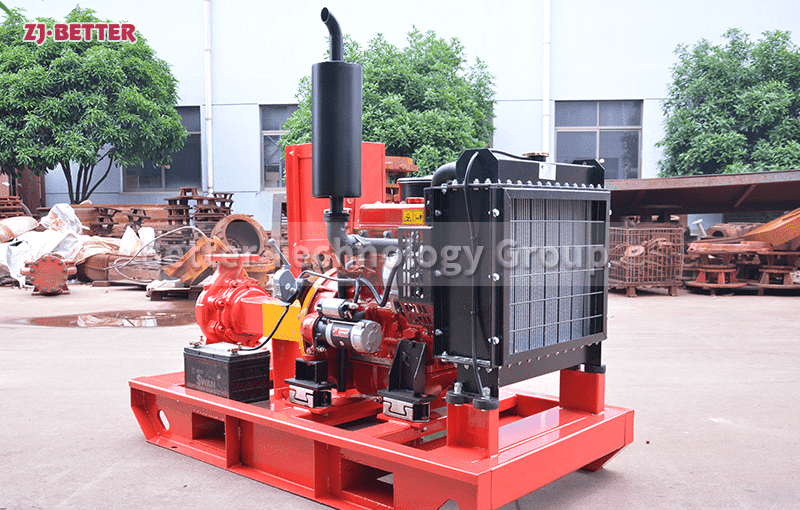

Analysis and introduction of product characteristics and main operating procedures of diesel engine fire pump sets

As a fixed fire-fighting equipment, the diesel engine fire-fighting pump set has been widely used in fire-fighting diversion, especially for fire-fighting water supply in unexpected situations such as no power supply or abnormal power supply (mains power). According to the needs of users, it can also be equipped with other diesel engines as power engines.

Operating procedures for diesel engine fire pump sets:

Start debugging:

1. Confirm that the coupling is aligned

2. Confirm that the diesel engine has been filled with fuel, the battery has been fully charged, the water cooling system is normal, and all valves have been opened.

3. Close the outlet valve of the water pump and open the inlet valve.

4. Turn on the power switch of the controller with the key. The readings of each indicating instrument should be normal, and then stop the machine.

5. The controller is set to the automatic position. Give the controller a self-start signal, and the diesel engine should start at normal speed.

6. If the flow head of the fire pump does not meet the requirements, the throttle can be adjusted appropriately to increase or decrease the speed of the diesel engine.

7. When the automatic stop signal is given to the controller, the diesel engine should be delayed to stop.

Emergency manual warm-up start:

For the fire pump group; when the day is cold and the engine cannot be started normally, the emergency manual preheating start method can be used. Use the key to turn on the manual preheating power supply, wrench the handle to the preheating position for 30~40 seconds, and then turn the handle to the preheating start to start the engine.