Analysis Video Of Fire Pump Set Test In Better Factory

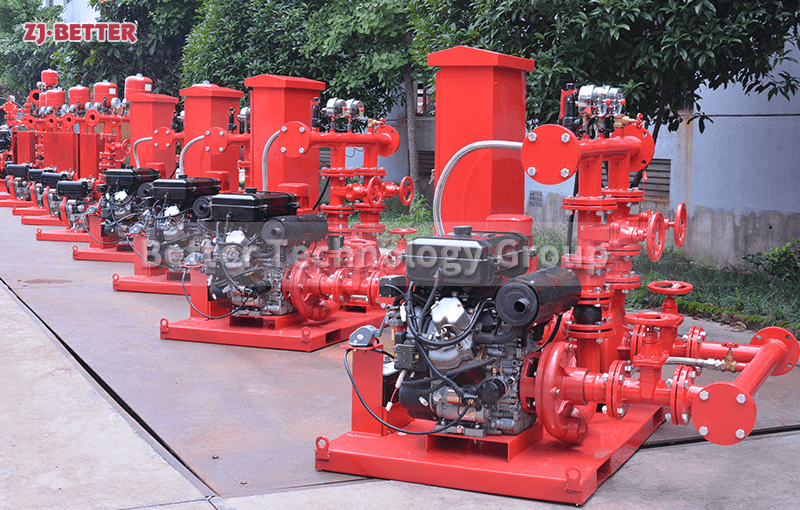

EDJ series fire pump set consists of Electric pump + Diesel pump + Jockey pump and all accessories.

The pressure switch and control cabinet can automatically turn on/off three pumps-the electric pump and jockey pump operate when there is electricity and the diesel pump activates when the power cuts,can work when the power is off.

EDJ fire pump set is a fire emergency system consisting of diesel engine fire pump set, electric motor fire pump set, jockey pump, pressure vessel, control cabinet, pipeline and automatic control system.

1.Adjust the pressure switch: the upper limit of the pressure of the jockey pump to 110% of the rated pressure, the lower limit to the rated pressure. The electric/diesel main pump pressure is limited to the rated pressure and the lower limit is 85% of the rated pressure.

2. Check before the test machine: a. The water level of the main pipe is higher than the inlet pipe or the negative pressure of the inlet pipe -0.02~-0.04, b. The diesel engine water tank is filled with the antifreeze with -5 °C, and the engine oil is CF-4 15W/ Type 40, the oil is added to the oil scale display position, and the battery switch is closed at a voltage of 12V/24V or higher.

3. Test machine start: The diesel engine first turns on the manual mode, starts the diesel engine speed in the idle position (rated 3000r/min idle speed 2000r/min, rated 1500r/min idle speed 1000r/min), the water temperature rises to 40-50°C, adjusts the throttle to the rated speed. (rated 3000r/min, rated 1500r/min).

4. Connect the control cabinet into the line, switch the automatic control pressure pump to pressurize the pipe network pressure to 110% of the rated pressure.

5. The diesel engine control panel button and the electric main pump control knob are all in the automatic position.

6. Test start: open the outlet valve, the pressure drops to the rated pressure, the jockey pump automatically opens, the pressure drops Up to 85% of the rated pressure, the electric main pump is automatically turned on, and the main power supply is turned off. The diesel pump is automatically turned on (dual power supply) Switch to the backup power supply).