Assembling the EJ Fire Pump Set

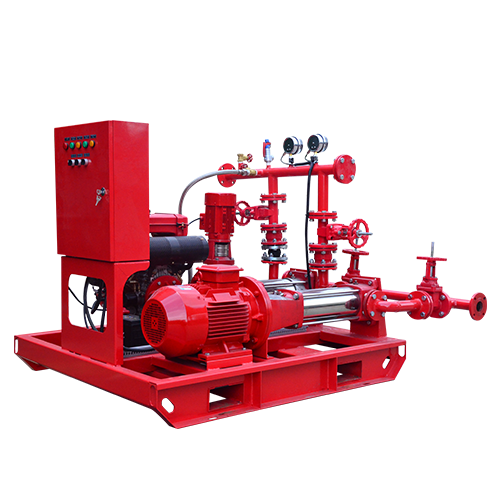

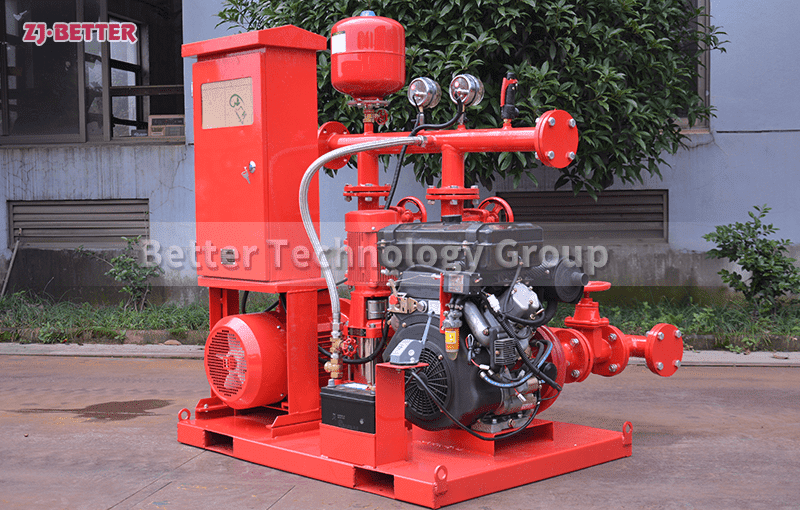

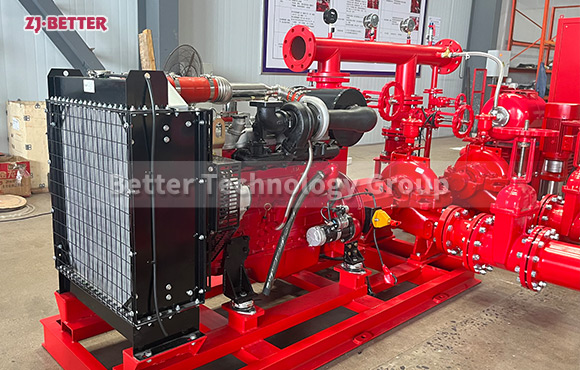

The fire pump refers to a clean water pump used for fire water supply, and a single pump that handles medium temperature below 80 degrees and is not corrosive. The pump set is the joint operation of multiple fire pumps to ensure the quantity and stability of the water supply. The electric motor fire pump group adopts multiple fire pumps powered by electric motors. The general fire water supply environment is equipped with one electric and one diesel fire pump as the reserve water pump to ensure sufficient emergency water consumption. The main components of the electric motor fire pump group are the motor and the pump body. The subdivision of the pump body is the pump casing, the impeller, the pump shaft, the bearing, the coupling, the sealing form, the lifting pipe, etc. The specific fire pump model is determined according to the environment and performance requirements. According to the material quotation required by the customer, accurate selection is beneficial to on-site use and reduces failure problems.

There are many types of electric motor fire pump sets, including long-axis fire pumps, vertical single-stage or multi-stage fire pumps, horizontal fire pumps, etc., and the installation environment and performance requirements (boosting/stabilizing, etc.) are selected as the benchmark. Fire pumps occupy an important position in life and production, requiring more but stable performance. As long as the appropriate fire pump manufacturer is selected to ensure the accurate quality and selection of the pump, there will be less troubles in daily use. There are two types of sealing forms of electric motor fire pump set: packing seal and mechanical seal. Different forms can be used in different environments. The difficulty of manufacturing and the selection of materials lead to different prices. For most users, the suitable material for fire pump selection is very good. The equipment does not need to exceed the required good materials and oversized models, otherwise it will easily cause many problems such as failures and difficulties in maintenance and repair.