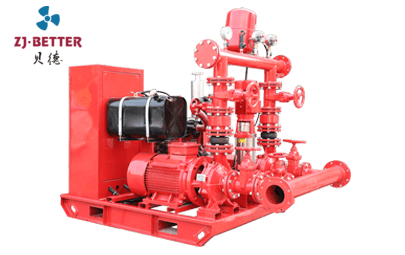

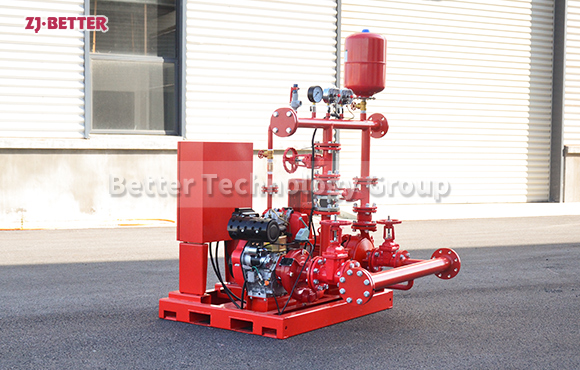

Better fire pump set complies with 3CF certification

The fire-fighting dual-power water supply equipment produced by Better Technology Co., Ltd. is designed and manufactured in accordance with GB 27898.5-2011 Stationary Fire-fighting Water Supply Equipment Part 5 <

1. The advantage of its products is that in the event of a fire, it is a more reliable way to ensure water safety

2. When the mains power is normal, the electric pump set is put into work. When the power supply fails and the electric fire pump cannot be put into use, some Shanghai machine fire pump sets can be put into operation automatically to ensure the normal fire extinguishing. Diesel engine fire pump sets are equipped with different configurations. One automatic function, which meets the requirements of the standard, ensures that the equipment is in a long-term normal standby state, and can be put into fire fighting work at any time

3. The fire-fighting dual-power water supply equipment is suitable for various emergency standby pump places

4. Strictly follow: GB 27898.5-2011 fixed fire water supply equipment