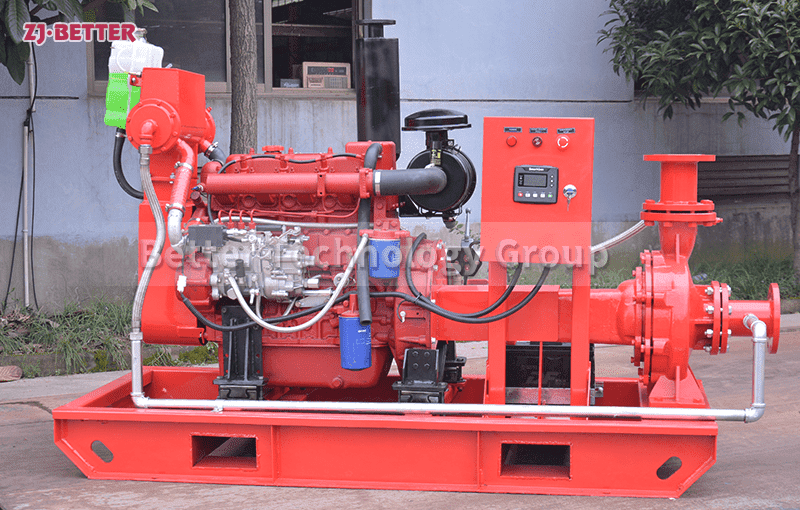

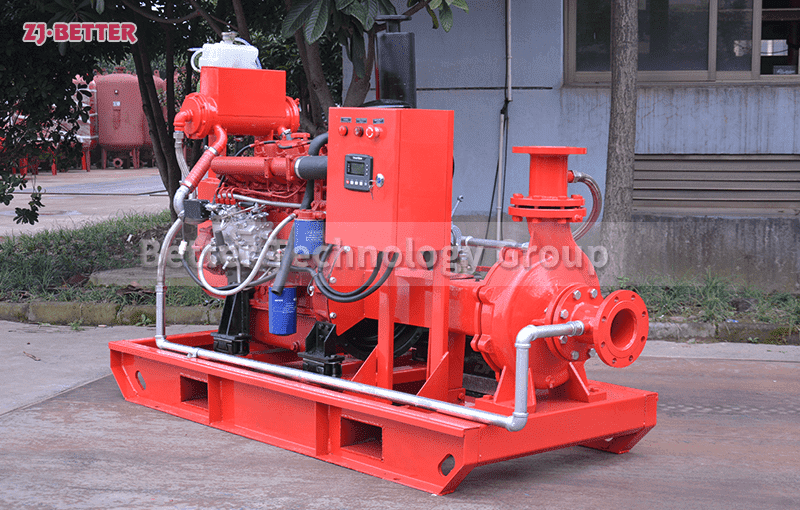

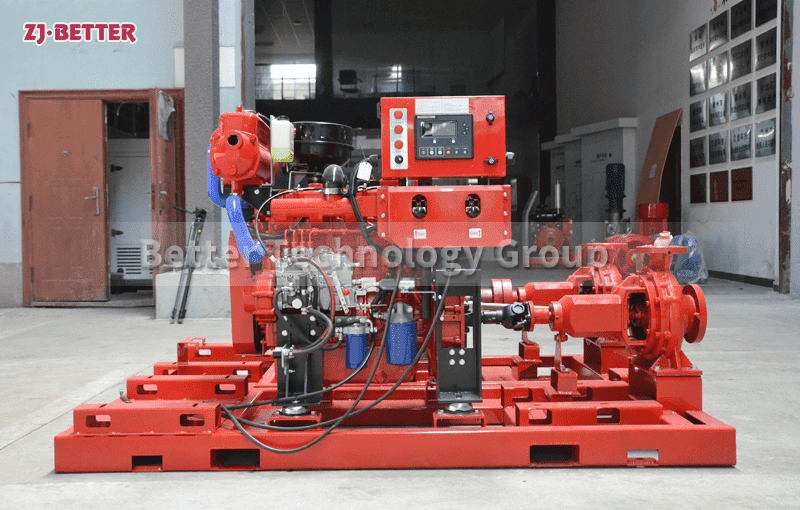

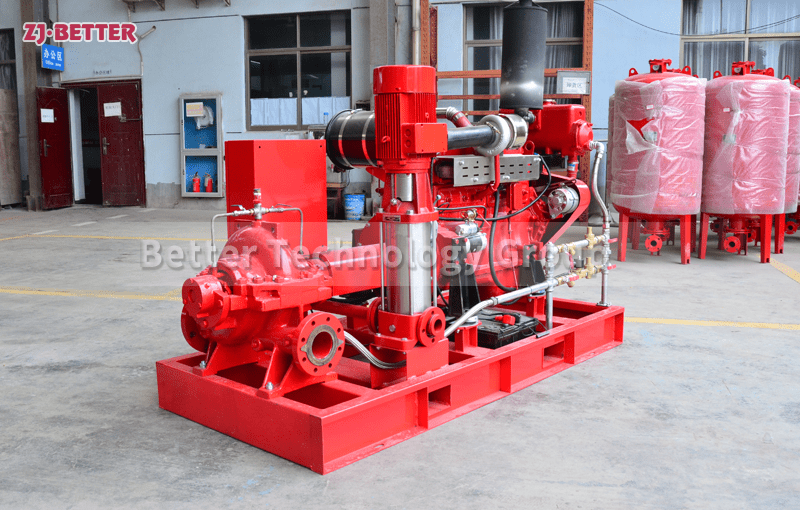

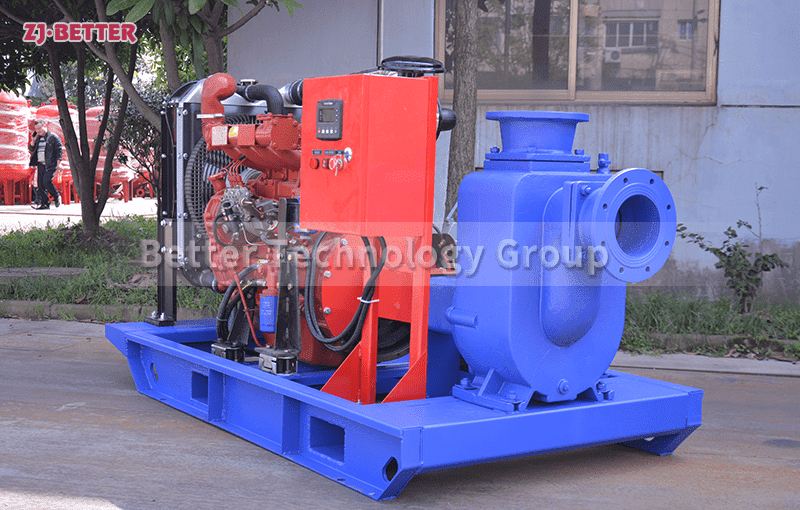

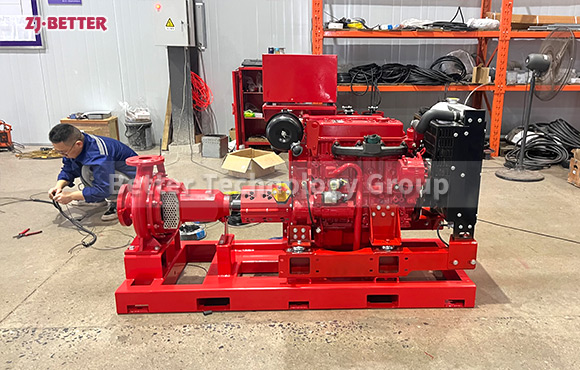

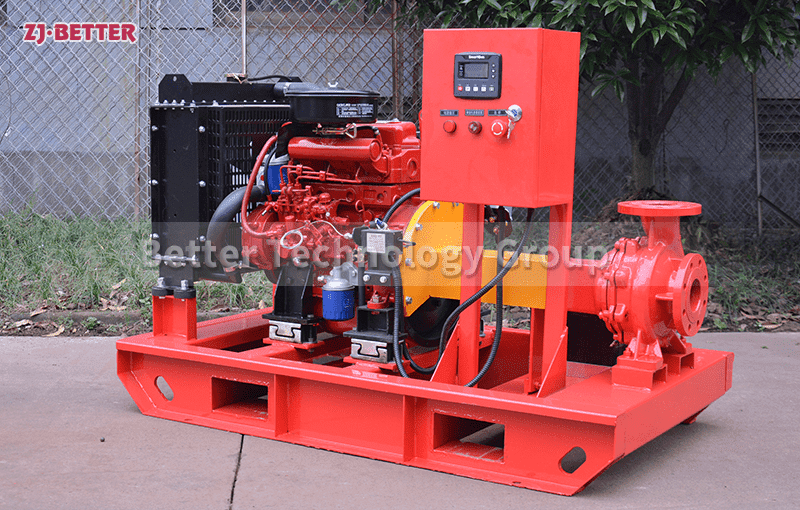

Better Manufactures Diesel Engine Double Suction Fire Pump

XBC series diesel double suction pump, large diesel flow pump set, adopts new type double suction pump + diesel engine + automatic control system (optional) combination of diversified and efficient, superior performance, safe and stable operation, low noise, energy saving and environmental protection, Easy installation and maintenance, long service life. The technical level has reached the domestic leading large flow. XBC series diesel double suction pump is mainly used for irrigation, municipal drainage, fire fighting, etc.

XBC series diesel pumps can be installed horizontally and vertically, and the driver can be installed left and right according to user requirements;

Flange holes can be according to GB and ISO standards;

According to the user’s needs, the rotation direction of the pump can be clockwise or counterclockwise.