Built for Harsh Environments: Performance of Enclosed Fire Pump Sets

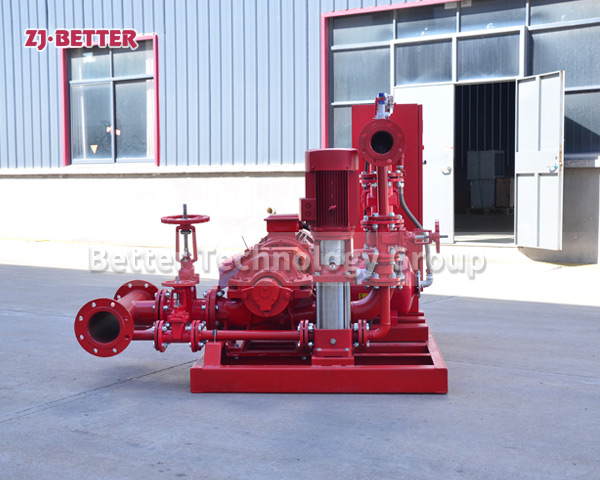

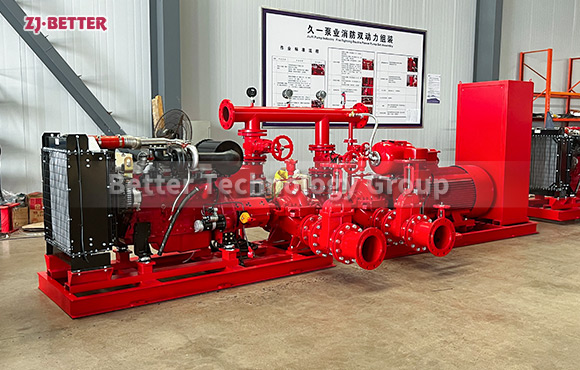

In today’s world of increasingly extreme weather and complex installation conditions, the enclosed fire pump set offers a robust and reliable solution for modern fire protection systems. With its fully enclosed cabinet design, this unit provides exceptional protection against dust, rain, and corrosion, while also delivering outstanding impact resistance. It is well-suited for tough environments such as construction sites, oil fields, ports, and underground parking facilities.

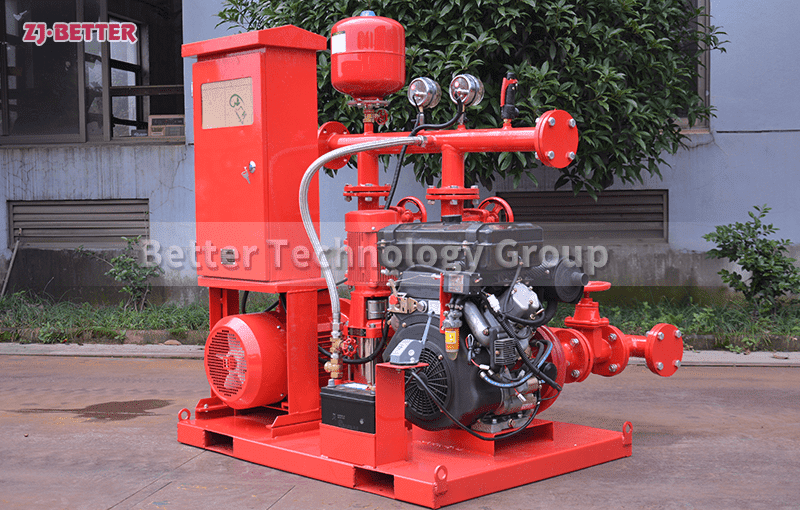

The system integrates a diesel engine, fire pump, control panel, and fuel tank within a weather-resistant metal housing. This design not only saves valuable space but also eliminates the need for a traditional pump room, reducing construction and maintenance costs significantly. Its louvered ventilation and multi-layer insulation effectively control heat and noise, ensuring quiet and efficient operation even under pressure.

Whether facing scorching heat, coastal humidity, or dusty desert climates, the enclosed diesel fire pump set remains a reliable safeguard—ready to perform at any moment and in any condition.

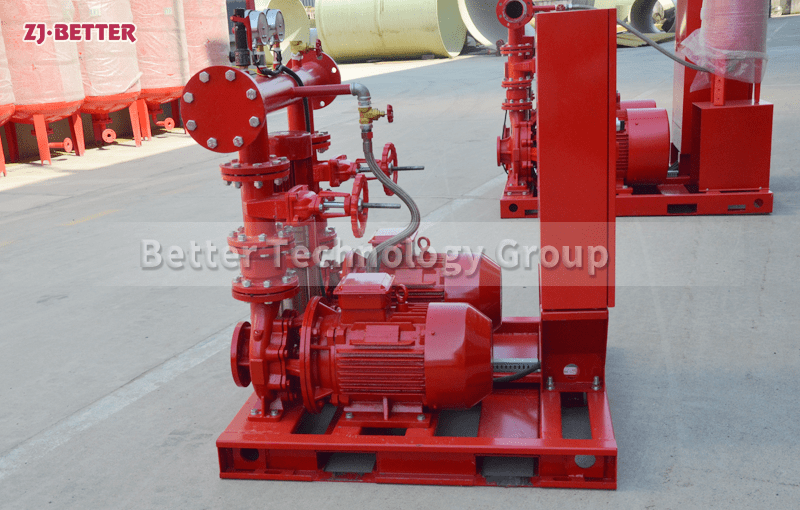

This enterprise is a modern manufacturer integrating R&D, production, sales, and technical services, specializing in high-quality fire pump systems for global clients. Its core products include diesel engine fire pump sets, electric fire pump sets, jockey pumps, sprinkler pumps, fire control panels, and intelligent integrated water supply systems. These solutions are widely applied in airports, high-rise buildings, industrial facilities, petrochemical plants, power stations, and marine terminals.

With modern production facilities spanning multiple buildings, the company is equipped with CNC machining centers, laser cutting machines, automated spray painting systems, and a dedicated hydraulic testing platform. Every pump unit undergoes strict performance testing—including pressure, flow, and head—to ensure reliability and superior functionality. The R&D team is composed of experienced engineers and industry experts, continuously refining product design and incorporating energy-efficient and smart control technologies.

On the service side, the company provides a comprehensive system that includes pre-sales technical consultation, customized in-project design, and responsive after-sales support—delivering a truly customer-centric experience. Whether it’s a standard model or a tailored engineering solution, clients receive professional, efficient, and dependable service.

Over the years, the company has exported its products to more than 60 countries and regions, earning a solid reputation and fostering long-term partnerships. Through ongoing innovation and global expansion, the company is steadily advancing toward a leading position in the international fire pump industry.