Can the diesel engine fire pump run for a long time?

Whether the diesel engine fire pump can run for a long time, the rescue of fire accidents is very important, of course, it is hoped that the fire equipment can operate safely for a long time. The principle and principle of diesel engine fire pump When all equipment is in normal operation, the switch should be set to the automatic position, and all operation signs are simple and clear. The working principle of the gas pressure equipment The pump room, underground pool, and all the mechanical and electrical equipment of the fire protection system are monitored by the equipment and firefighters, and are regularly inspected, maintained, maintained, cleaned, and recorded.

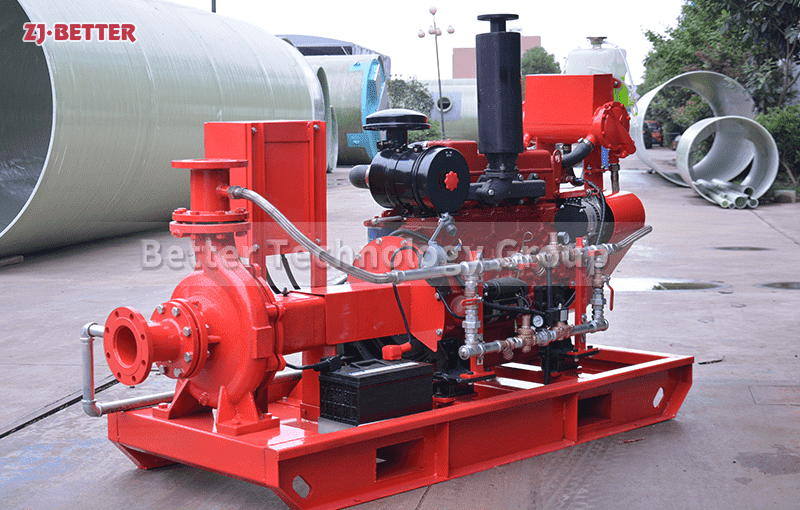

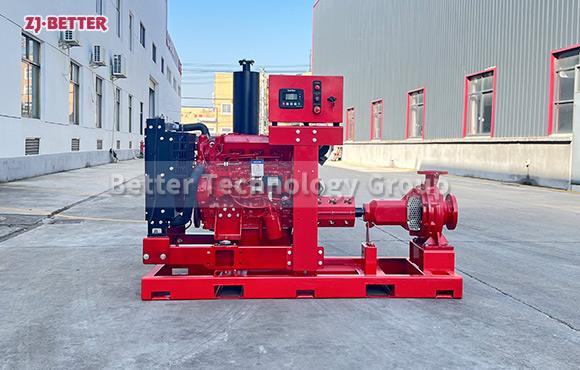

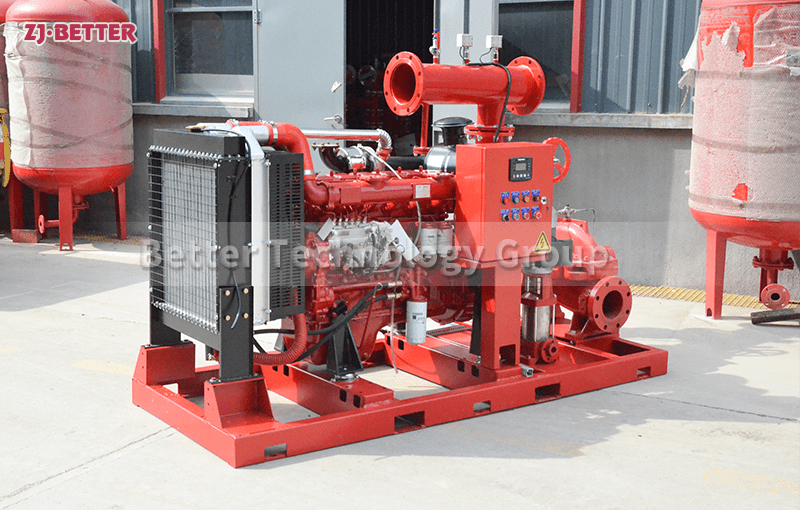

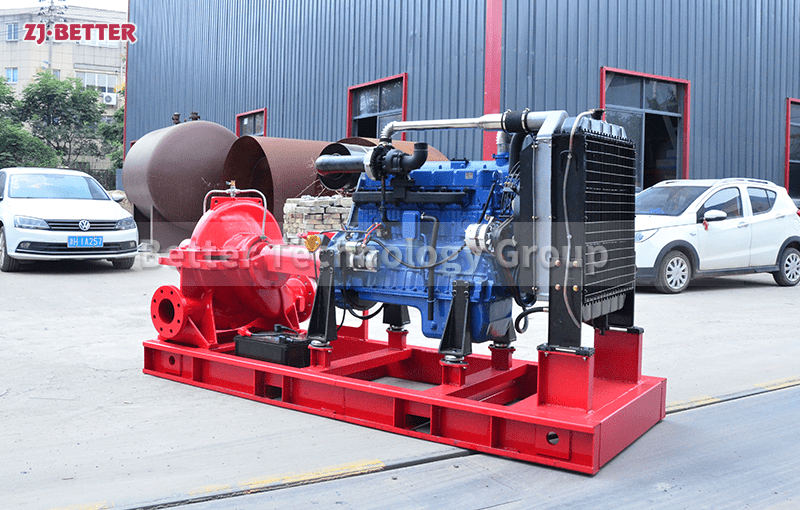

Diesel engine fire pump automatically starts control panel, oversized inspection hole cover for easy cleaning. The part of the pump body and the pump cover of the diesel engine fire pump is split from the back of the impeller, which is the so-called rear door structure. The advantage is that the maintenance is convenient. During maintenance, the pump body, the suction pipeline, the discharge pipeline and the motor are not moved, and the rotor part can be withdrawn for maintenance only by removing the intermediate connecting piece of the coupling.

The casing of the diesel engine fire pump constitutes the working chamber of the pump. The impeller, shaft and rolling bearing are the rotors of the pump. The suspension bearing part supports the rotor part of the pump, and the rolling bearing receives the radial and axial forces of the pump. In order to balance the axial force of the diesel engine fire pump, most pumps are provided with sealing rings at the front and rear of the impeller, and a balance hole is provided on the back cover of the impeller. Due to the small axial force of some pumps, there is no seal on the back of the impeller. Ring and balance hole. The axial sealing ring of the diesel engine fire pump is composed of a packing gland, a packing ring and a packing to prevent air intake or a large amount of water leakage.