Characteristics of Diesel Engine Fire Pump Usage

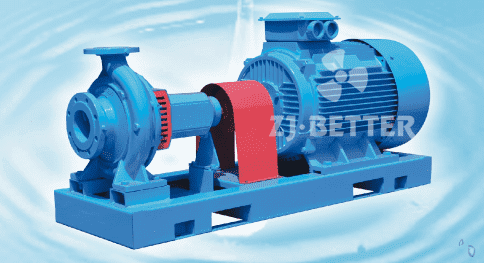

The fire pump set is composed of a diesel fire pump and an electric fire pump. The pump set is a horizontal, single-suction, single-stage centrifugal pump. It has the characteristics of high efficiency, wide range of performance, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. It is used to transport clear water or other liquids whose physical and chemical properties are similar to water. It can also be used to transport hot water, oil, corrosive or abrasive media by changing the material of the pump’s flow parts, sealing form and adding a cooling system.

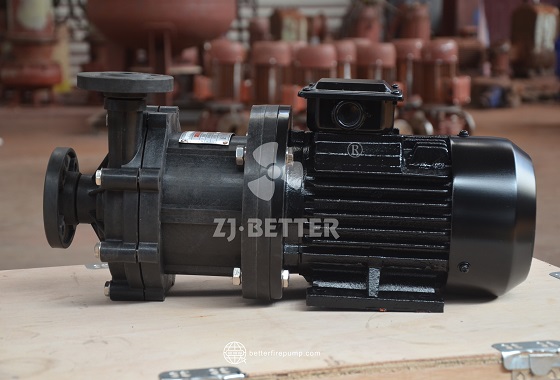

The diesel engine fire pump is installed together with electrical instruments and other equipment as a complete set. It has complete functions, high degree of automation, compact structure, automatic fault alarm and receiving start signal, completes the starting procedure by itself, and can quickly put into full-load operation. Diesel engine fire pump units can be equipped with shock absorbers, rubber flexible joints, and bellows silencers for exhaust ports as required. In case of insufficient fuel, low battery voltage, high lubricating oil temperature, overspeed, etc., an alarm device is equipped to ensure that the diesel engine starts in a low temperature environment. The whole system is safe, reliable and easy to use.