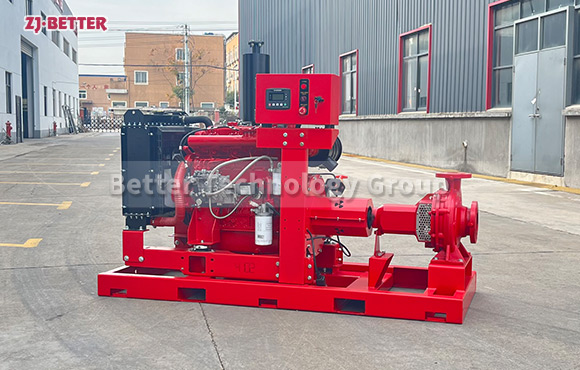

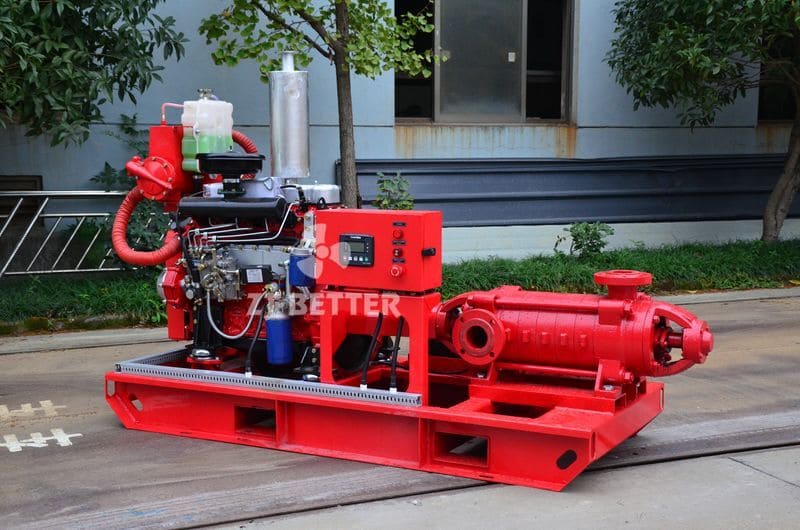

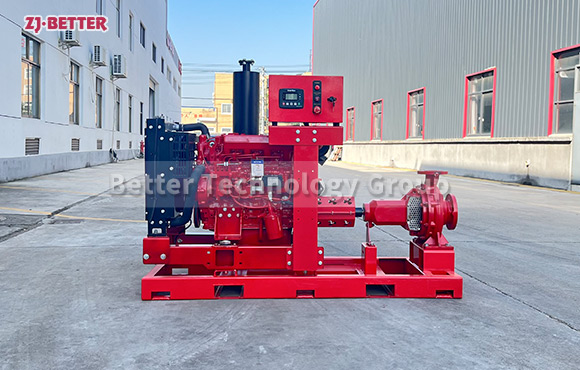

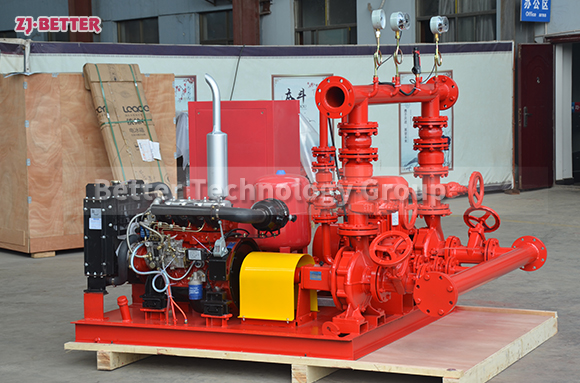

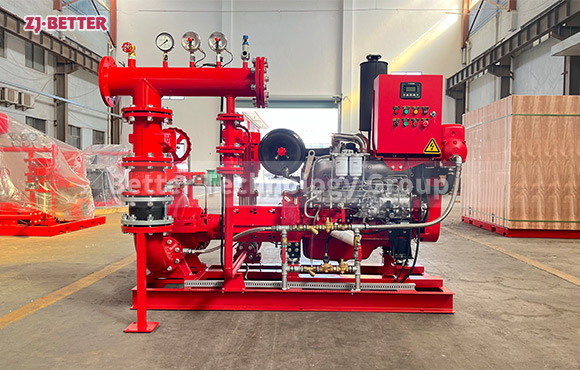

Chemical diesel engine pump set

The national standard name of the diesel engine fire pump is “engineering diesel engine fire pump group”, and the national standard model is XBCL/Q where L is the lift value and Q is the flow value. XBC diesel engine fire pump set is the latest according to the national standard GB6245-2006 “fire pump performance requirements and test methods”. This series of products has a wide range of lift and flow, and can fully meet the fire water supply in various occasions such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, textiles and other industrial and mining enterprises.

After more than 10 years development, BETTER PUMP has won awards including all kinds of certificates awards by governments institutional and society. As we have professional R&D team, our products has got the Certificate of Utility Model Patent and Certificate of Design Patent. And our factory has got Production License, authentication from SGS, Export License from government. We are also have many honor, the enterprise of Vice Chairman of Quzhou Network Association, the cooperative enterprise with Quzhou colleges and universities. We are also a member of Wenzhou Commerce, Quzhou disabled people internship foundation. All of our products accord with machinery industries standard JB/T5118-2001.