Chinese Manufacturer Produces Standard Fire Pump Set Equipment

The fire pump is a high-tech product, which is characterized by high efficiency, fast pumping speed, very strong sealing, and low leakage, which can also be said to be no leakage. The use of fire pumps is very extensive, of course, the most important one is used in the fire protection industry, it is also used in water treatment, environmental protection industry and so on. Among these uses, the fire protection industry uses the most. The fire protection industry makes full use of the advantages of fire pumps, which is the advantage of fast pumping. Because most of the work in the fire protection industry is to extinguish fires, the fire pump plays a very important role. Fire pumps are not just used in the firefighting industry. Fire pumps are also used in many other places. In larger industries, such as industry, as well as urban water supply and drainage, and water transportation for the construction of high-rise buildings, there is also water delivery over relatively long distances. There are also smaller industries, such as heating and boilers.

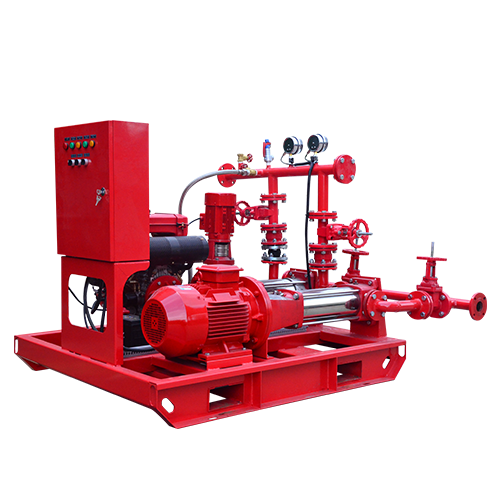

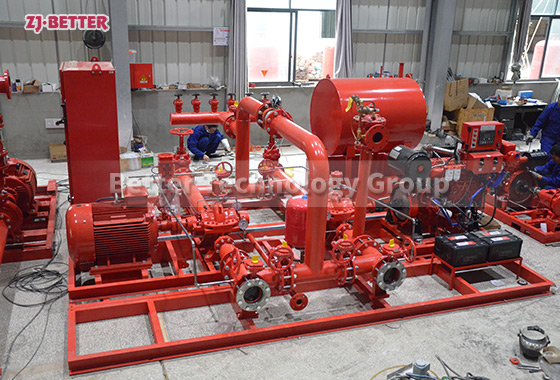

1. Electric pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller

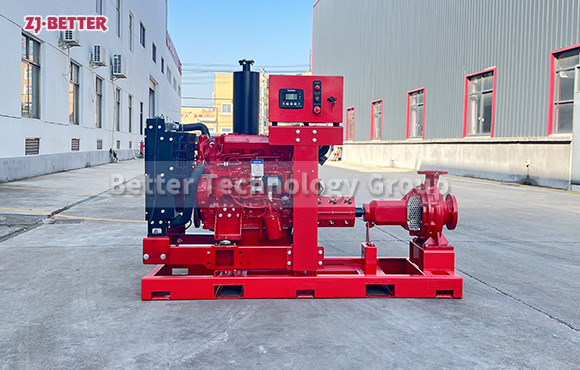

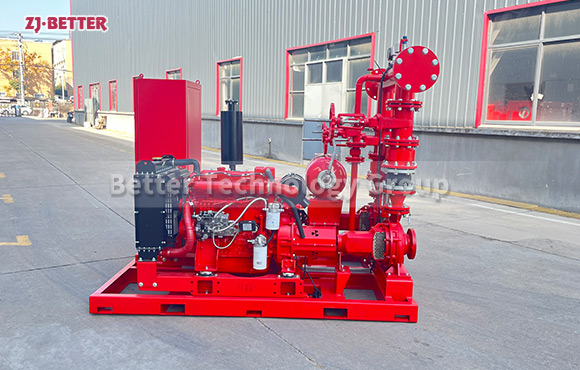

2. Diesel engine pump, with capacity and head equal to electric pump, with fuel tank, water tank,fan, control box

Diesel engine pump also can use end suction ,split case ,multistage pump can according to the flowrate ,head .

Different Diesel Model use different tank capacity.

3. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump

Jockey material casing :cast iron ,shaft and impeller SS304

4. Control panel: Auto Control of electric pu