Common Control Methods for Diesel Engine Fire Pumps

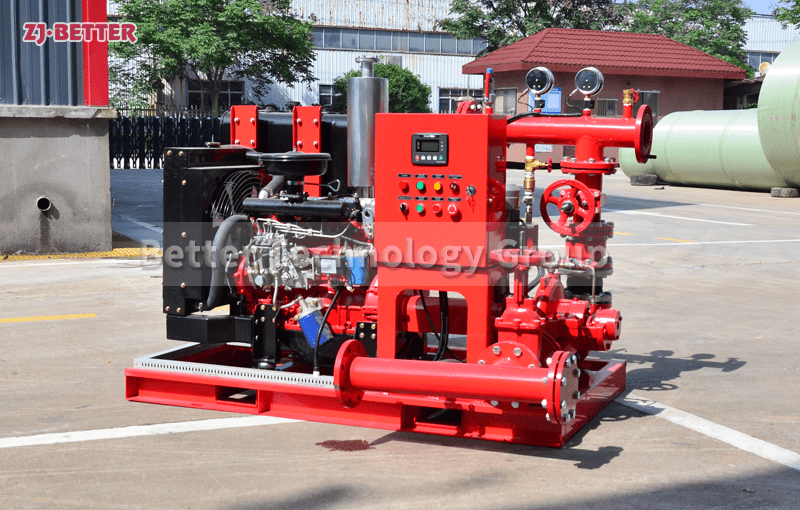

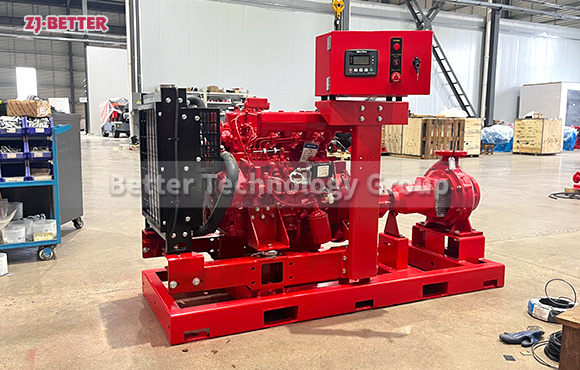

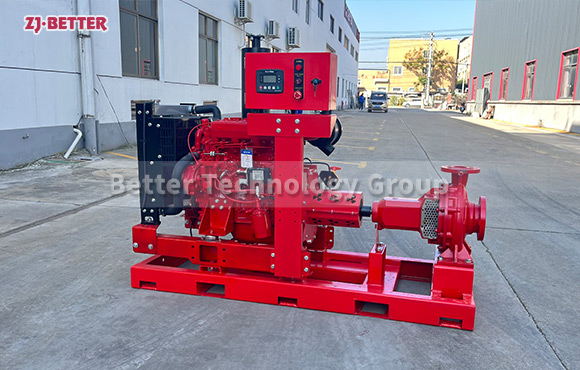

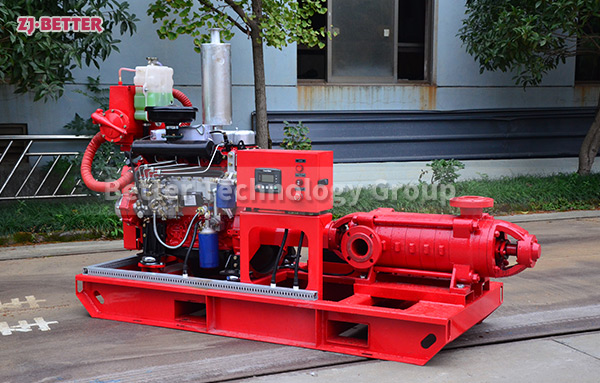

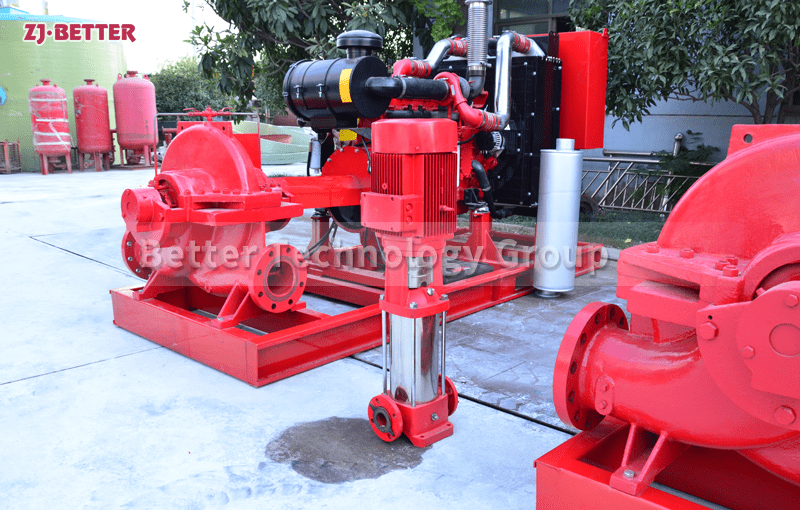

Diesel engine fire pumps can be used for fire water supply in warehouses, docks, airports and other places. We usually choose the appropriate diesel engine fire pump model application according to the head, flow rate, power, medium properties, required materials, etc. provided by the user. In order to avoid mistakes, the loss caused by the installation environment will also be considered comprehensively to ensure stable and reliable efficiency.

Diesel engine fire pumps can be widely used in environmental protection, water treatment and fire protection departments to transport various liquids by using their own advantages. As for the common control methods of diesel engine fire pumps, there are mainly the following three types:

1. Manual control: the diesel engine fire pumps are operated by pressing the control button manually, and the operation process is automatically completed by the preset program.

2. Automatic control: When the diesel engine fire pump is affected by fire protection, pipeline pressure or other automatic control signals, the preset program of the diesel engine fire pump will be automatically completed.

3. Remote control: The computer will perform remote monitoring, remote control, remote communication, and remote adjustment in real time through the network.