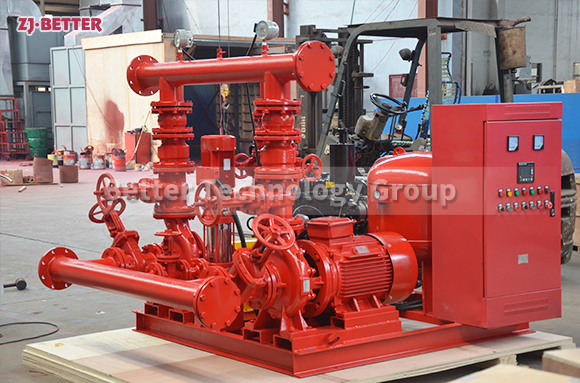

Customizable XBC-IS Diesel Engine Fire Pumps

Flow:80-4000 GPM

Head:3-15 Bar

Power:11-1000 kw

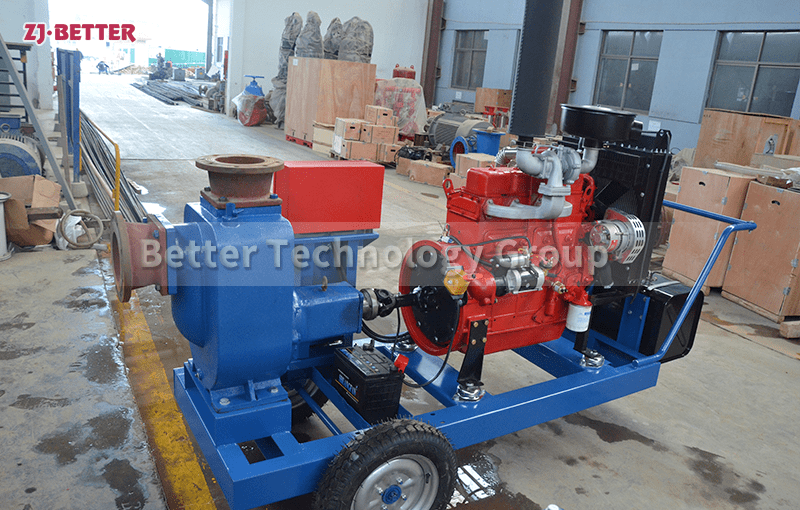

The XBC-IS Diesel Fire Pump Set is a versatile solution suitable for a wide range of applications. From hotels, hospitals, and sports arenas to chemical plants, refineries, metallurgical facilities, energy plants, and pharmaceutical companies, this pump set ensures reliable fire protection. It is also ideal for shopping malls, commercial complexes, office buildings, and high-end residential towers. Whatever the setting, the XBC-IS Diesel Fire Pump Set delivers dependable performance to safeguard lives and properties from fire risks.

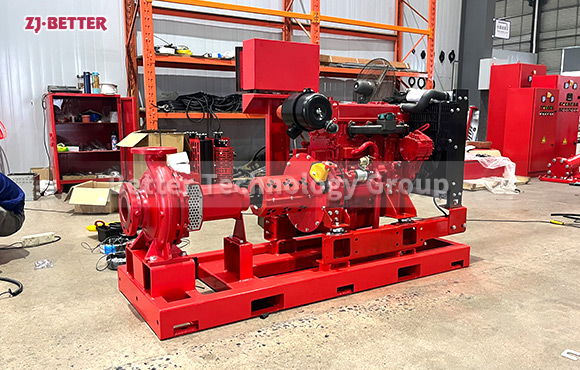

The XBC-IS Diesel Fire Pump Set offers several key advantages:

1.Automatic Startup: The diesel engine pump set can automatically start and operate at full load within 15 seconds upon receiving signals such as fire alarms, network pressure changes, power outages, or other startup triggers.

2.Automatic Charging: The battery can be charged automatically using either mains power or the diesel engine’s charging generator, ensuring smooth startup of the pump set.

3.Automatic Alarm System: The pump set features automatic alarm protection for low oil pressure, high water temperature, and over speed conditions, providing timely alerts and shutting down when necessary.

4.Automatic Preheating: The preheating function keeps the diesel engine in standby mode, ready for emergency operations at any time.

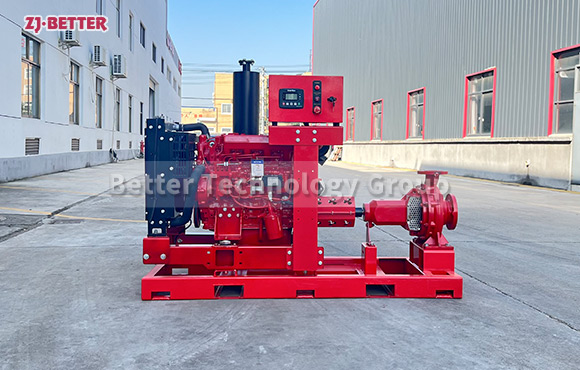

5.Direct Coupling Design: For diesel engine pump sets up to 360kw, the innovative direct coupling technology connects the diesel engine and water pump directly with an elastic coupling joint. This design minimizes potential points of failure, significantly shortens the startup time, and enhances the reliability and emergency performance of the pump set.