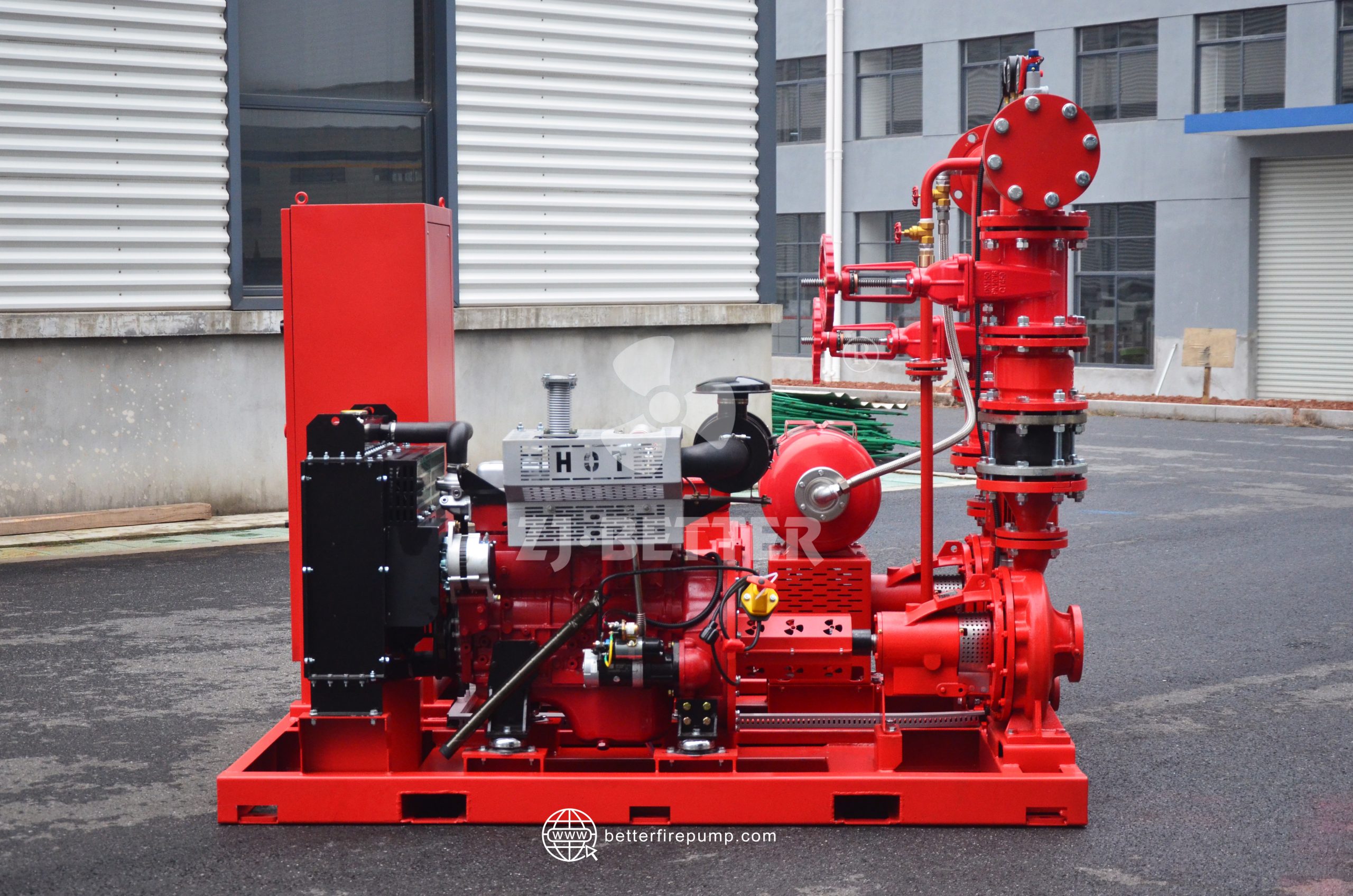

Diesel Engine and Right-Angle Gearbox Combination: An Efficient Power Transmission Solution

The diesel engine with right-angle gearbox combination is a high-performance power transmission solution widely used in various industrial applications. It features a diesel engine as the primary power source and a right-angle gearbox for efficient power redirection and speed matching. This compact and reliable duo enhances production efficiency, reduces energy consumption, and provides a stable power source for industrial automation and ship propulsion systems. Its adaptability to diverse climate conditions and load demands further reinforces its significance in modern industries.

The diesel engine serves as the primary power source, boasting high efficiency and excellent torque output. On the other hand, the right-angle gearbox plays a crucial role in power transmission by redirecting power at a 90-degree angle while accommodating different speed requirements. This combination’s compact design and high transmission efficiency have made it highly sought after in the industrial sector. Its simple structure, stable operation, low noise, and long lifespan render it an indispensable component in industrial automation and mechanical power transmission.

The combination of a diesel engine and a right-angle gearbox finds extensive application in various industrial settings. From mixers, conveyors, cranes, and mining machinery to metallurgical equipment and packaging machinery, this combination provides stable and reliable power transmission, enhancing production efficiency and overall performance. Moreover, it plays a crucial role in ship propulsion systems, serving as the primary propelling transmission device for different types of vessels, ensuring a reliable power source for maritime operations.

The combination of a diesel engine and a right-angle gearbox offers high-performance power transmission and exceptional cost efficiency. The diesel engine provides robust power output, and the right-angle gearbox efficiently transmits power to the target equipment using advanced gear transmission technology, optimizing energy utilization to the fullest. This advantage is particularly significant in industrial production, as it reduces energy consumption and helps enterprises save on operational costs.

The diesel engine and right-angle gearbox combination excels under diverse climate conditions and varying load demands. Whether operating in extreme cold or hot environments or facing different load conditions, it performs reliably and maintains efficient transmission capabilities. This reliability makes it a widely preferred choice across diverse industrial applications.