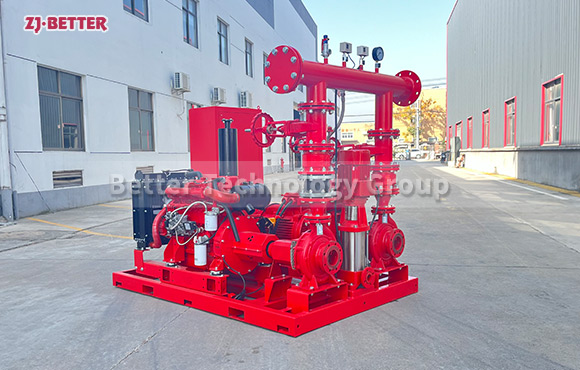

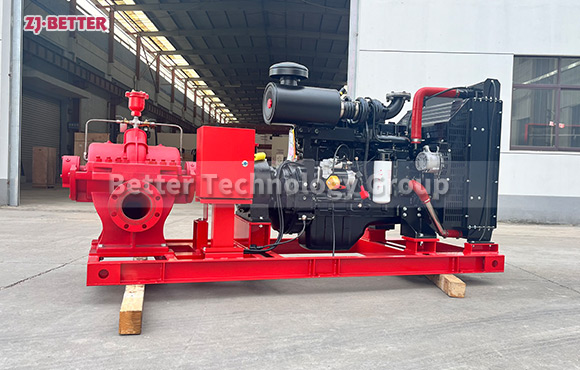

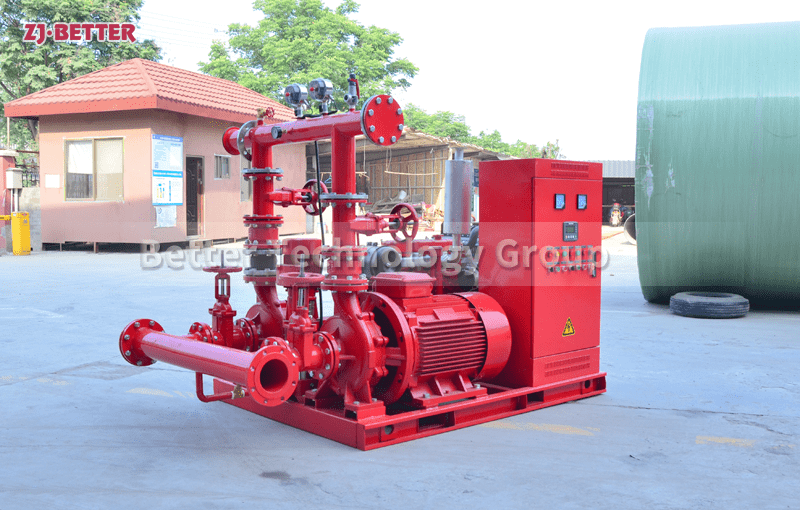

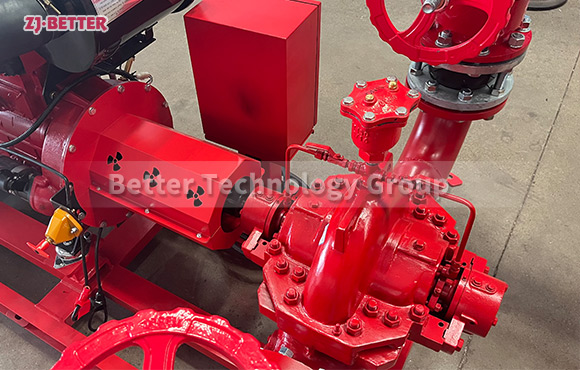

Diesel Engine Fire Pump Assembly

With the continuous progress of the times, the application of diesel engine fire pumps is becoming more and more extensive. Diesel engine fire pump is a common necessary facility. Only when the fire signal comes, and the electric water pump fails or the power supply is cut off, the diesel engine fire pump will automatically start. The diesel engine fire pump is installed together with the electrical instrument, with complete functions, compact structure, automatic fault alarm, accepting the starting signal, and can automatically complete the starting procedure and run at full load quickly. When the diesel engine fire pump is insufficient in fuel, low battery voltage, and high lubricating oil temperature , enough to ensure that the diesel engine fire pump starts in a low temperature environment, the entire system of the diesel engine fire pump is safe, reliable, and easy to use.

Diesel engine fire pumps can be widely used in environmental protection, water treatment and fire protection departments to transport various liquids by using their own advantages. There are three common control methods for diesel engine fire pumps:

1. Manual control: The diesel engine fire pump is manually controlled by pressing the control button, and the operation process is automatically completed by the preset program.

2. Automatic control: When the diesel engine fire pump is affected by fire and pipeline pressure or other automatic control signals, the preset program of the diesel engine fire pump will be automatically completed.