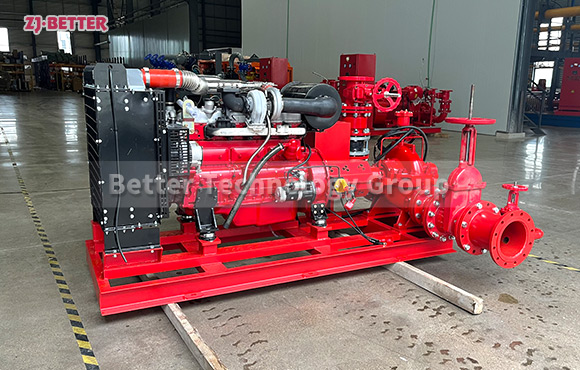

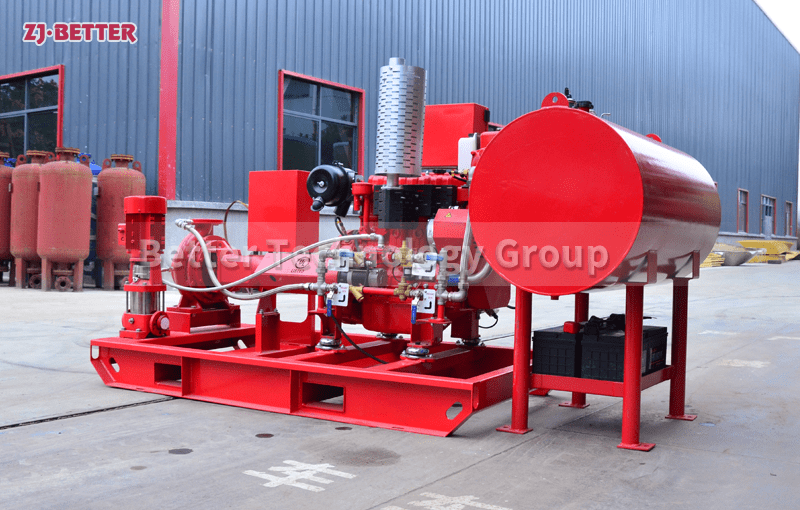

Diesel engine fire pump has superior performance and complete protection functions

The intelligent diesel engine fire pump products produced by our company are equipped with an unattended intelligent system as standard. The product has the characteristics of mature technology, high degree of automation, superior performance, complete protection functions, reasonable structure, simple installation and high cost performance. At the same time, in order to meet the different needs of users and reasonable investment, the products are divided into multiple application series such as fire pumps, industrial emergency pumps, agricultural water pumps, marine water pumps, trailer mobile water pump stations, etc., which can be linked and switched with electric fire pumps. Supporting water pumps: single-stage fire pump, multi-stage fire pump, single-stage split double-suction fire pump.

1. Various fire hydrants and spray fire main pumps.

2. It is suitable for all kinds of fire boosting and stabilizing pumps.

3. Fire protection systems such as living quarters.

4. Fire water systems for industrial and civil buildings.

5. Applicable to various oil depots, oil loading and unloading docks, logistics parks and other occasions with high fire protection requirements.