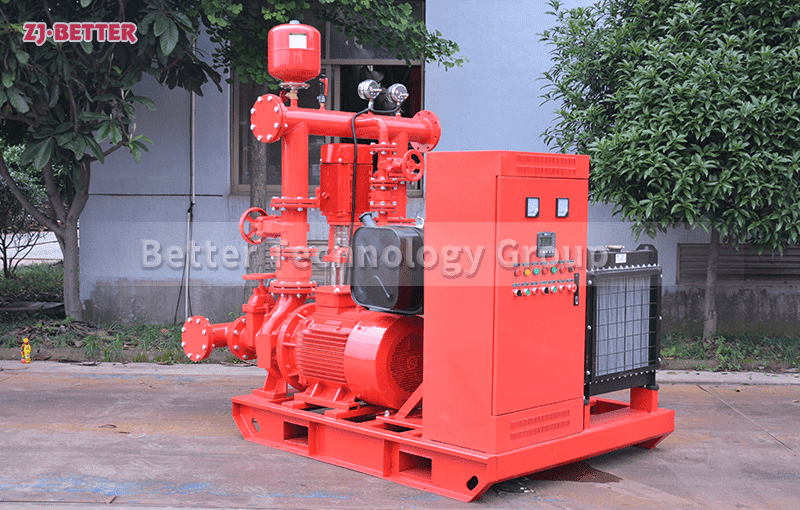

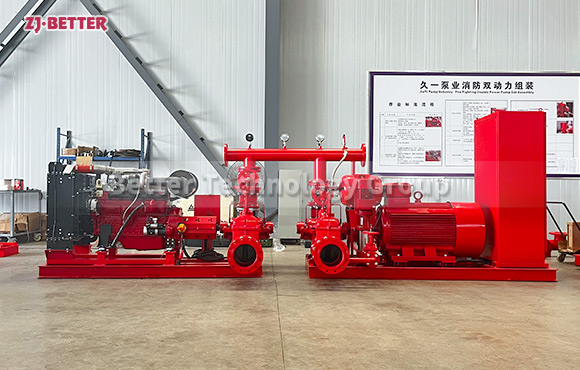

Diesel engine fire pump is a large fire pump

Diesel engine fire pumps are large-scale fire pumps. Diesel engine fire pumps are currently the hottest fire pumps on the market, especially in large warehouses, docks, airports, petrochemicals, power plants, and liquefied gas stations. This kind of fire pump with large flow and high power is often needed.

Diesel engine fire pump:

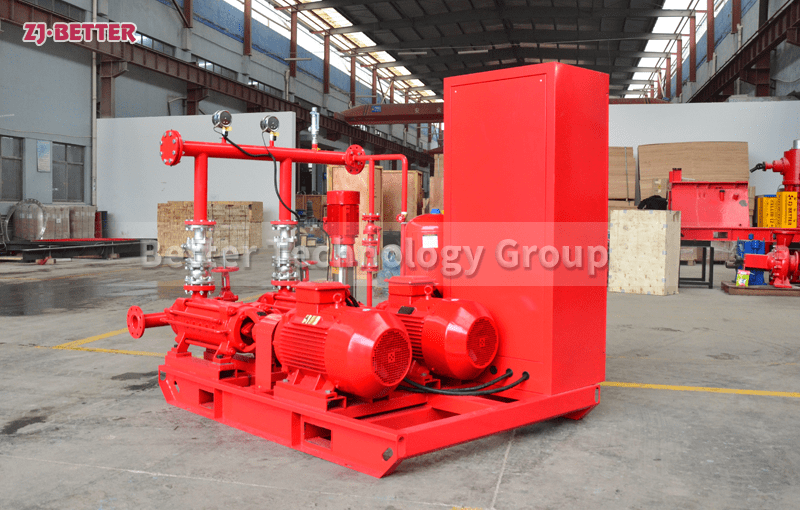

1. After receiving the fire alarm/pipe network pressure/power failure/or other starting signals, the diesel engine pump unit of the equipment can automatically start and put into full-load operation within 15 seconds;

2. The diesel engine pump unit below 360kw adopts the domestically created diesel engine and water pump direct connection technology through elastic couplings, which reduces failure points, greatly shortens the starting time of the unit, and increases the reliability and emergency performance of the unit;

3. The unit can be equipped with AC220V cooling water preheating and heating device, which can ensure the normal operation of the unit in an environment below 5°C;

4. The automatic alarm function will automatically alarm and protect according to the diesel engine’s low oil pressure, high water temperature and other faults, and then alarm and stop when overspeed, reducing damage;

5. The built-in fuel tank runs longer; the diesel engine fire pump automatically starts the control panel, and the inspection hole cover is easy to clean;

6. The pump body and the pump cover of the diesel engine fire pump are divided from the back of the impeller, which is the so-called rear door structure;

7. Do not move the pump body, suction pipeline, discharge pipeline and motor during maintenance, only need to remove the intermediate connecting piece of the coupling, then the rotor parts can be withdrawn for maintenance, which is very convenient.

-2.jpg)