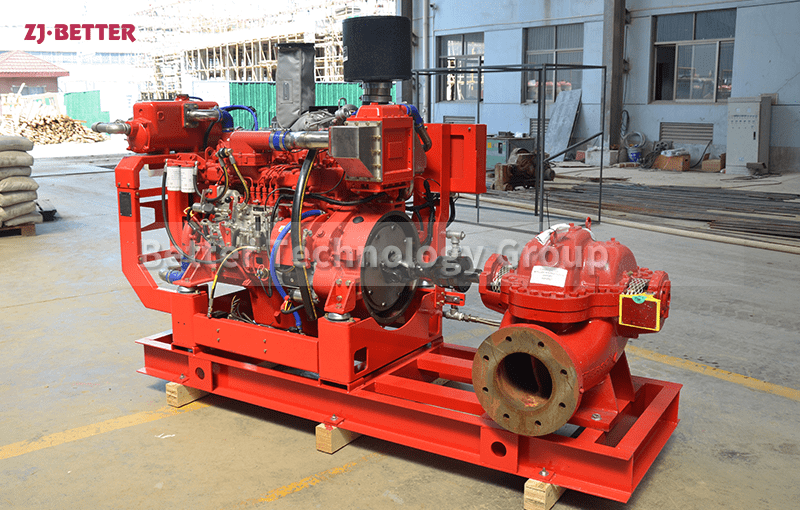

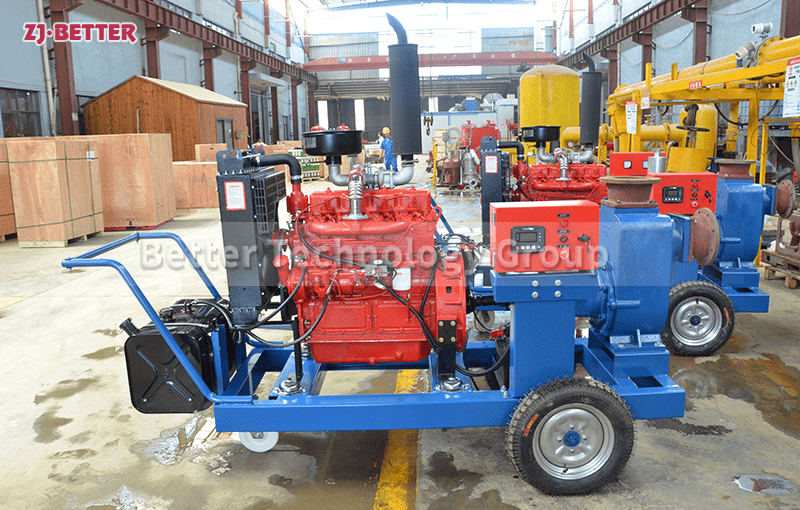

Diesel engine fire pump maintenance knowledge

Maintaining a diesel engine fire pump is crucial to ensure its reliable operation in case of emergencies. Below are some essential maintenance tips for a diesel engine fire pump:

Regular Inspections: Schedule periodic inspections by a certified technician to assess the condition of the fire pump. Inspect the engine, fuel system, cooling system, electrical connections, and other critical components.

Battery and Electrical System: Inspect and maintain the battery and electrical connections to ensure reliable engine starting. Clean any corrosion from terminals and replace weak batteries promptly.

Run Regular Tests: Perform routine tests of the diesel engine fire pump to verify its functionality. Regular testing will help identify potential issues and ensure the pump is ready for operation during emergencies.

Follow Manufacturer’s Guidelines: Always adhere to the maintenance guidelines provided by the fire pump manufacturer. These guidelines are tailored to the specific model and will help extend the life of the equipment.

Train Personnel: Ensure that the personnel responsible for maintaining and operating the diesel engine fire pump are well-trained and knowledgeable about its components and maintenance requirements.

Emergency Plan: Have a contingency plan in place in case the fire pump fails during an emergency. This plan should include alternative water sources or backup fire suppression systems.

Remember, regular maintenance is essential to keep the diesel engine fire pump in optimal working condition and ready to protect lives and property during critical situations. Always prioritize safety and follow best practices when handling and maintaining fire protection equipment.

Maintaining a diesel engine fire pump is crucial to ensure its reliable operation in case of emergencies. Below are some essential maintenance tips for a diesel engine fire pump:

Regular Inspections: Schedule periodic inspections by a certified technician to assess the condition of the fire pump. Inspect the engine, fuel system, cooling system, electrical connections, and other critical components.

Battery and Electrical System: Inspect and maintain the battery and electrical connections to ensure reliable engine starting. Clean any corrosion from terminals and replace weak batteries promptly.

Run Regular Tests: Perform routine tests of the diesel engine fire pump to verify its functionality. Regular testing will help identify potential issues and ensure the pump is ready for operation during emergencies.

Follow Manufacturer’s Guidelines: Always adhere to the maintenance guidelines provided by the fire pump manufacturer. These guidelines are tailored to the specific model and will help extend the life of the equipment.

Train Personnel: Ensure that the personnel responsible for maintaining and operating the diesel engine fire pump are well-trained and knowledgeable about its components and maintenance requirements.

Emergency Plan: Have a contingency plan in place in case the fire pump fails during an emergency. This plan should include alternative water sources or backup fire suppression systems.

Remember, regular maintenance is essential to keep the diesel engine fire pump in optimal working condition and ready to protect lives and property during critical situations. Always prioritize safety and follow best practices when handling and maintaining fire protection equipment.