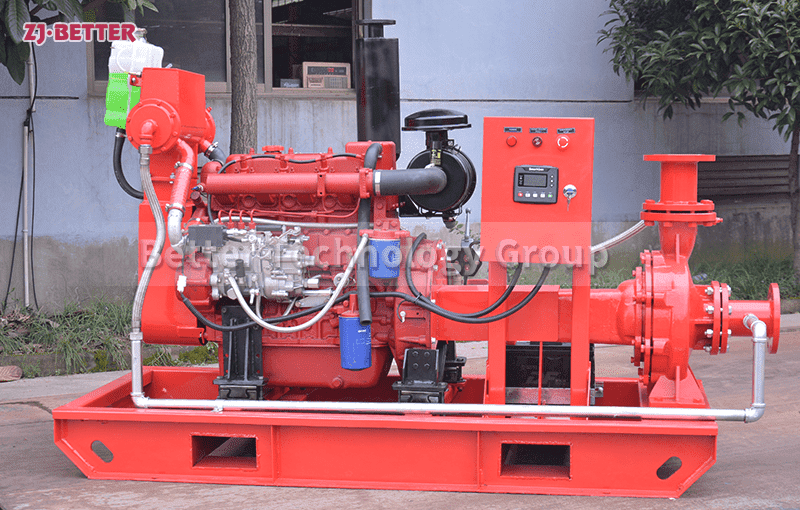

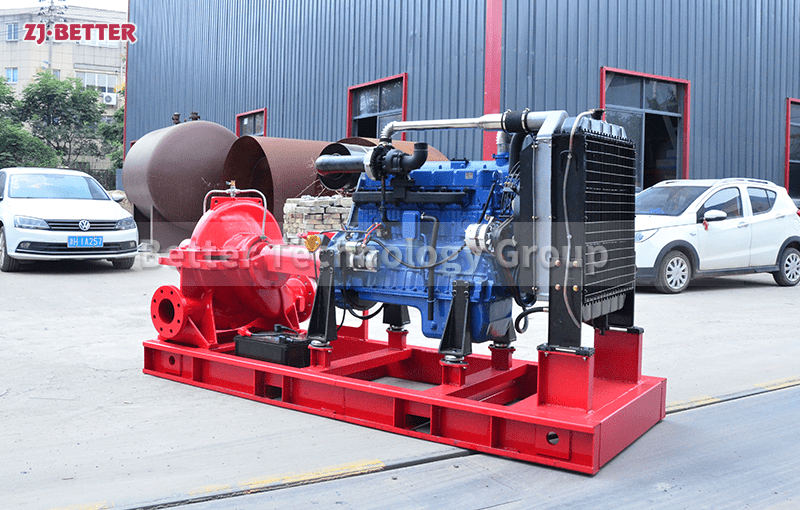

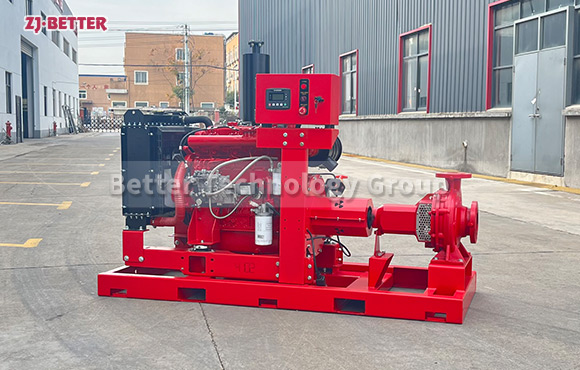

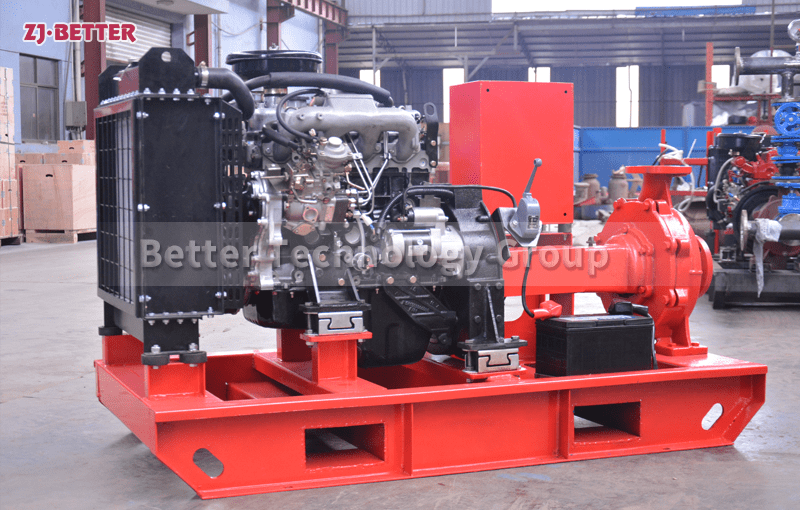

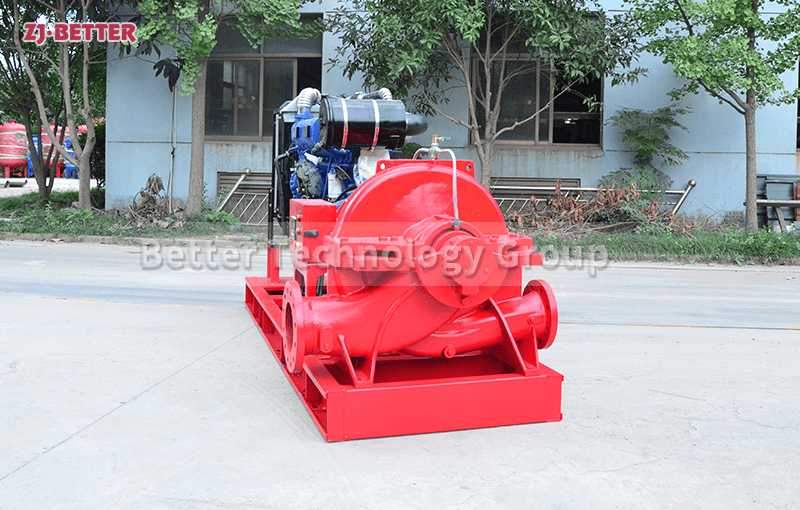

Diesel engine fire pump plays a pivotal role in the pump equipment industry

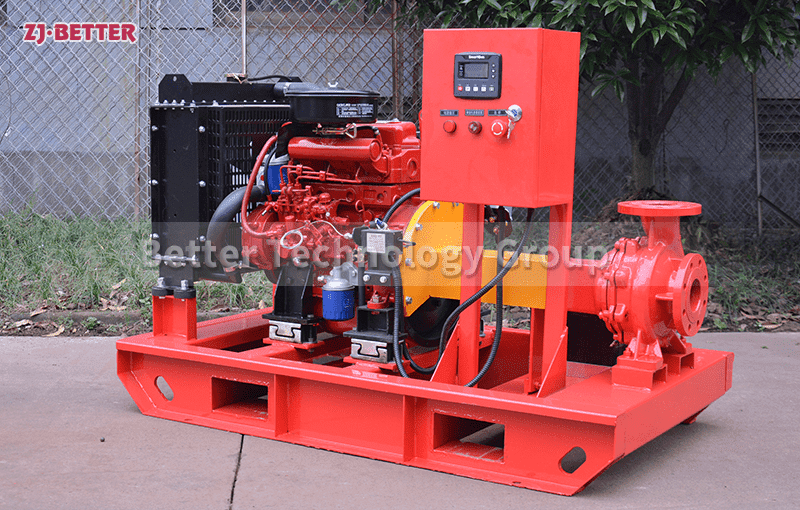

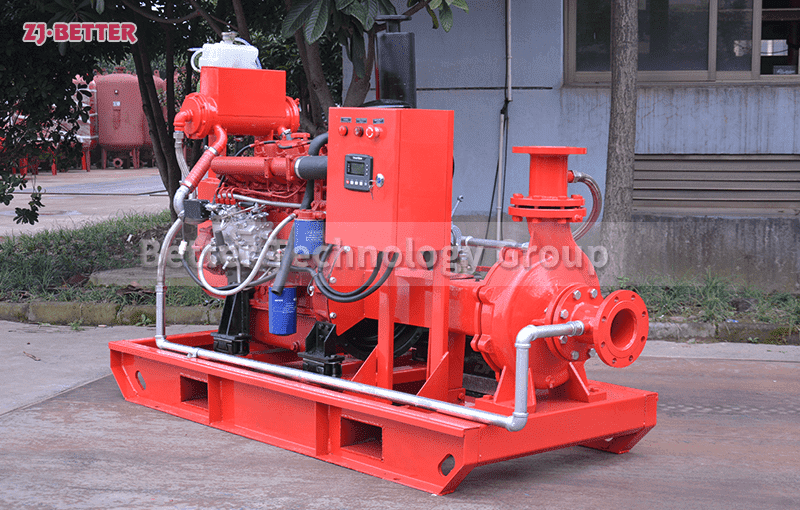

In order to avoid the wear of the diesel engine fire pump, a shaft sleeve is installed to protect the part where the shaft passes through the packing cavity. An O-ring is installed between the sleeve and the shaft to prevent air intake or water leakage along the mating surface. The transmission mode of the diesel engine fire pump is connected with the electric motor by lengthening the elastic coupling. The rotation direction of the pump, viewed from the driving end, is clockwise. The inlet and outlet flanges of the diesel engine fire pump are designed according to the pressure of 1.6Mpa, and the pipeline is convenient to match.

Diesel engine fire pumps are relatively common in life, and their performance requirements are relatively high. In ordinary use, more attention should be paid to maintenance, so as to prolong the service life of the pump. Because diesel fire pumps are not omnipotent, there will be some problems in daily use, so when choosing equipment, we must pay attention to whether the quality of the equipment meets the national standards. As fire equipment, all kinds of equipment must be To ensure performance, avoid affecting use in disaster situations and delaying rescue.