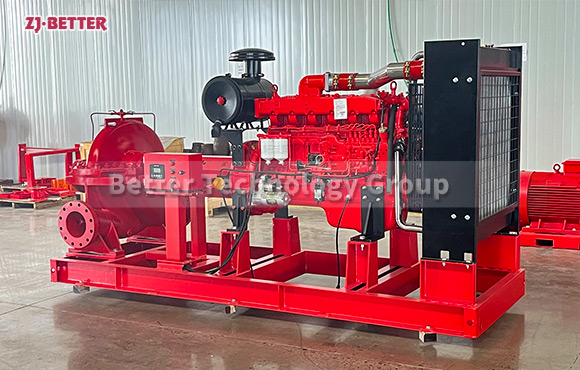

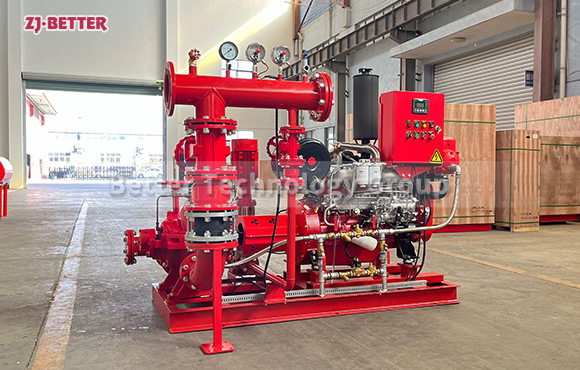

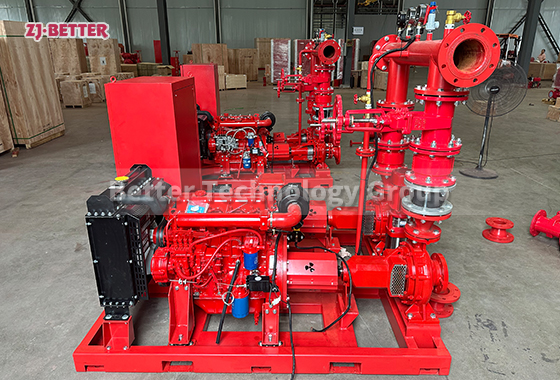

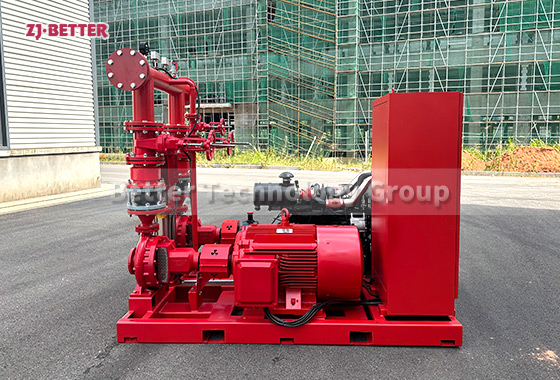

Diesel engine fire pump product overview and performance characteristics

The fire pumps used in the complete set of diesel engine fire pumps can be the IS series single-stage type, the S series new single-stage two-stage type, and the D-type series segmental multi-stage type produced by our company. The diesel engine water pumps used in this series of equipment are made of domestic or imported high-quality products. They have the characteristics of good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use, and high degree of automation. They are advanced and reliable fire-fighting equipment.

The diesel fire pump has three perfect starting functions:

1. Manual start function: Manual and automatic interlocking can be completed through the transfer switch and manual start function can be realized:

2. Automatic and manual function: three starts are allowed, if the three starts are unsuccessful, a “start failure alarm” will be issued and the start state will be automatically exited; after one start is successful, the time to start to rated load is 5-10-15S (depending on the capacity of the unit) );

3. Emergency manual direct start function: When the automatic control device fails, the emergency manual direct start function can be realized.