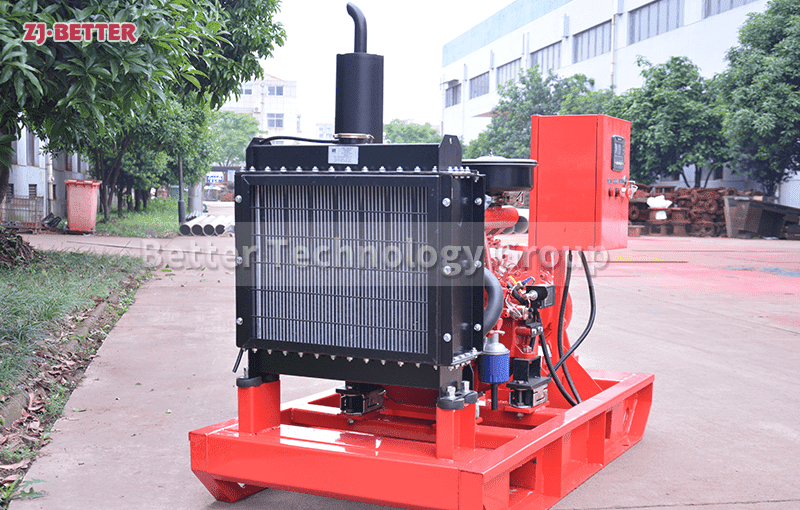

Diesel engine fire pump set for automatic control system

Diesel engine fire pump, as a fixed fire extinguishing equipment, has been widely used in fire diversion, especially in the case of no power supply or abnormal power supply and other emergencies, other diesel engines can also be equipped as power engines according to the needs of users.

The diesel engine fire pump has automatic, manual and fault self-checking functions. It can monitor the working state of the whole process, restore the function of failure start, automatic pre-lubrication and automatic restart of preheating, so that the equipment start-up is safer and more reliable. It has the functions of central control room remote control, remote control and field bus connection. The battery is fully automatic floating charge (constant current, constant voltage, trickle charge) mode to ensure that the battery is in a standby state at any time. Diesel engine fire pump is easy to use, equipped with remote instrument and instrument, which can be connected to the control center as needed, easy to install and use, and easy to maintain.