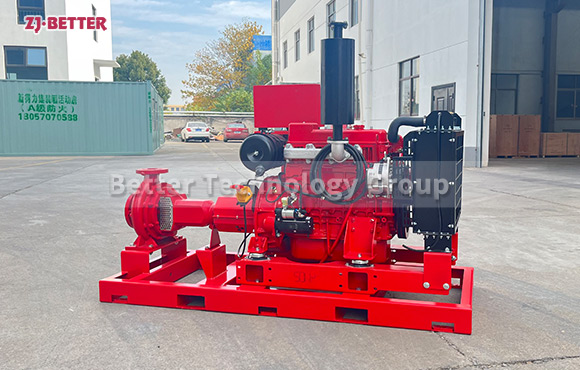

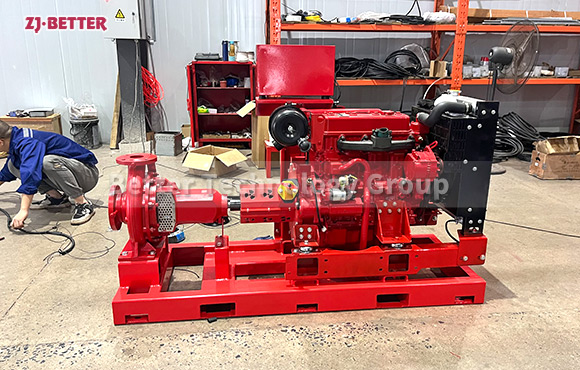

Diesel engine fire pump set is an advanced and reliable fire fighting equipment

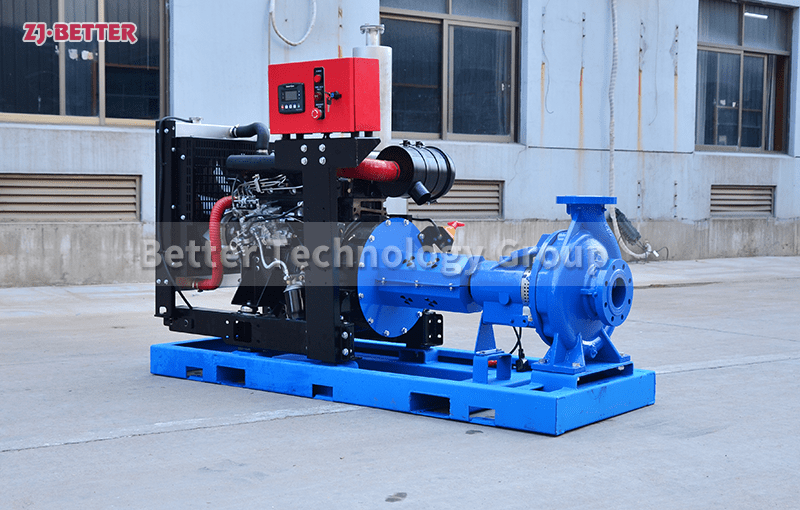

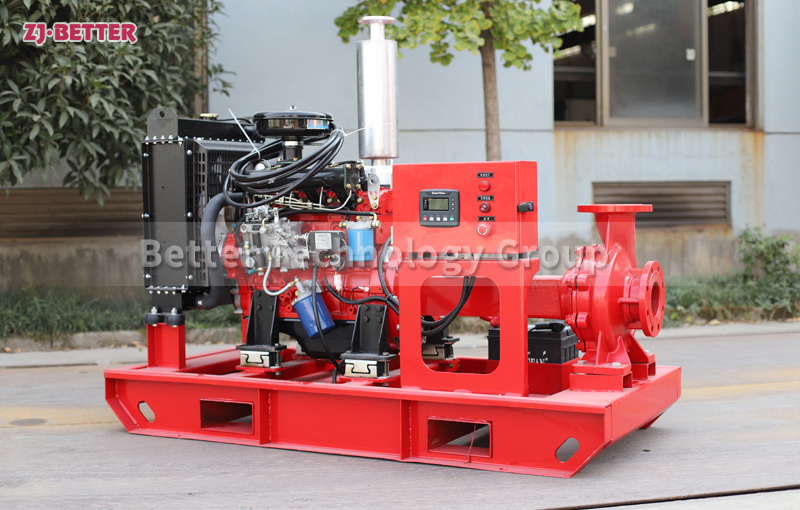

Diesel engine fire pumps are mainly suitable for fire water supply and foam fire extinguishing systems in petrochemical, natural gas, power generation, cotton and linen textiles, warehouses, airports, docks, high-rise buildings and other industries. It can also be used in occasions such as water ships, offshore oil tankers and fire fighting ships. The unit adopts imported diesel engine and fire pump. It has the characteristics of quick start, reliable water diversion, reasonable power reserve, stable operation, high degree of “three modernizations”, wide range of pressure and flow, etc. It is an advanced and reliable fire-fighting equipment.

It can be combined with electric pumps, jockey pumps, etc. to form an automatic water fire-fighting water supply system, and can be linked with the fire control center.

When the pump set receives the starting command, if the mains power is cut off, the automatic control cabinet of the diesel engine will immediately send a start signal to the starting motor of the pump set to start the motor to start the diesel engine at idle speed, and then gradually adjust the throttle to accelerate the diesel engine to the rated speed . The control system will automatically monitor the operation of the diesel engine, such as the oil pressure, oil temperature, speed of the diesel engine, outlet pressure of the water pump, etc., and determine whether the diesel engine starts normally through automatic monitoring. If the start fails, the control system will send a restart signal, and if the three starts fail, the automatic control system will send a failure alarm. When the pump set receives a signal that the pressure of the pipeline network is restored or the mains power is restored to normal, the pump set will quickly slow down and stop automatically after monitoring the idle position for a period of time.