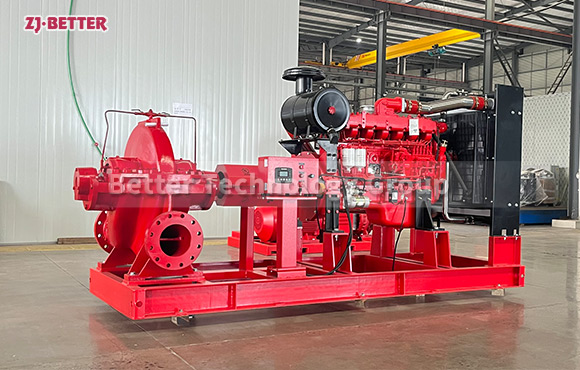

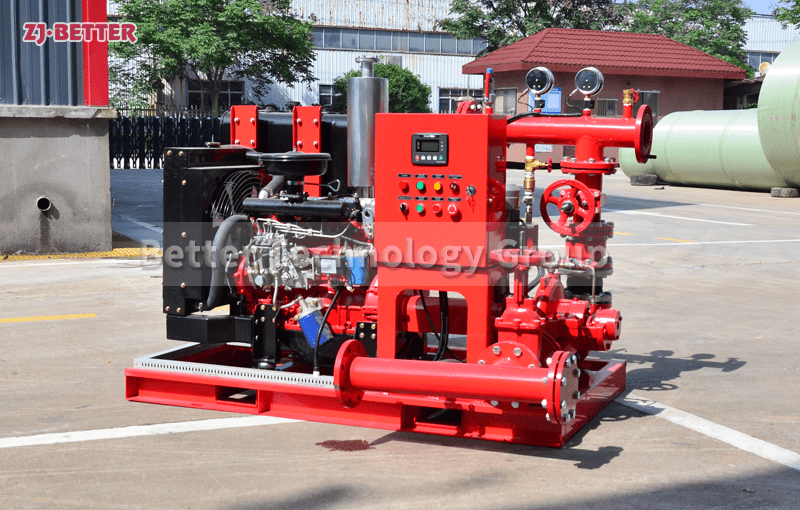

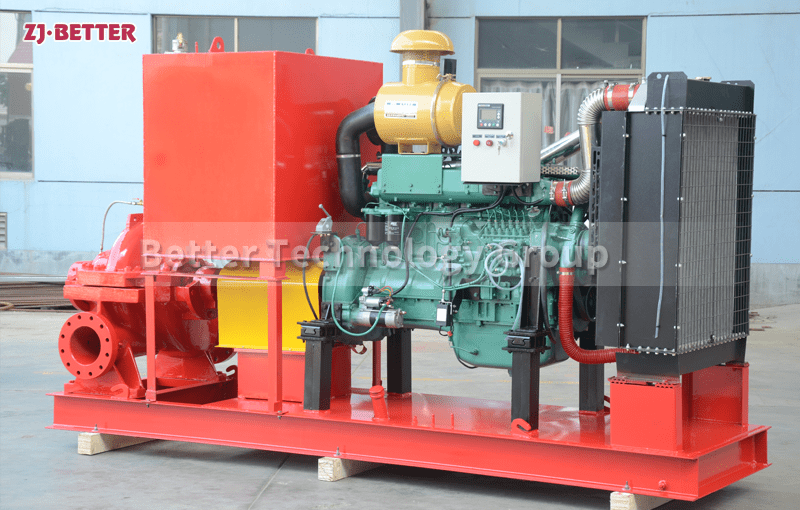

Diesel Engine Fire Pump Set Test

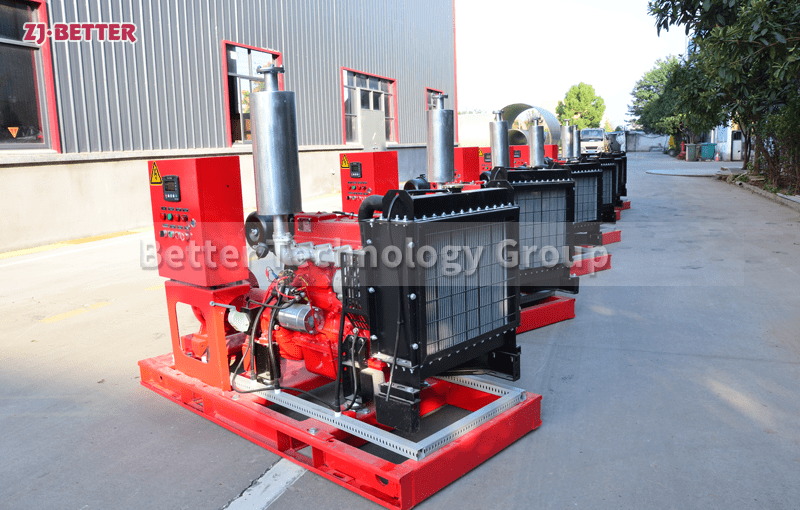

1.The packing of our products conforms to the national standard, meet customer needs, and standard handling and transportation.

2.All products are tested before delivery to ensure no quality problems.

3.As for after-sales problems, we can dispatch engineers to solve them on site, so you can buy our products at ease.

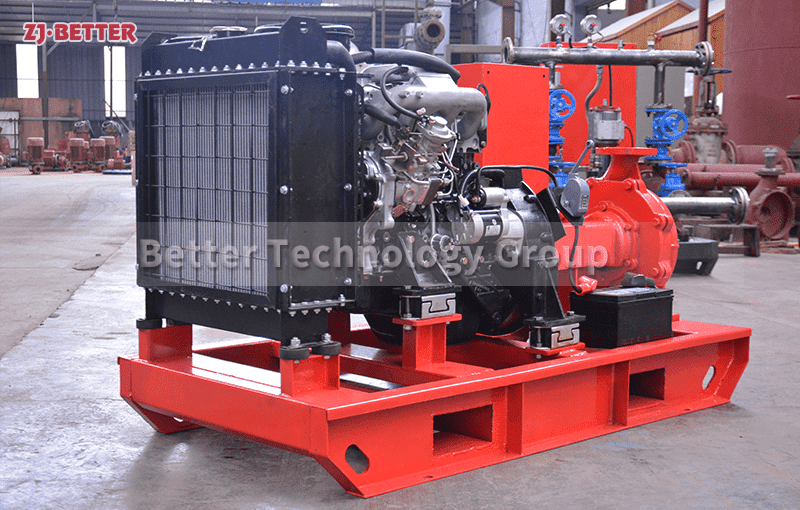

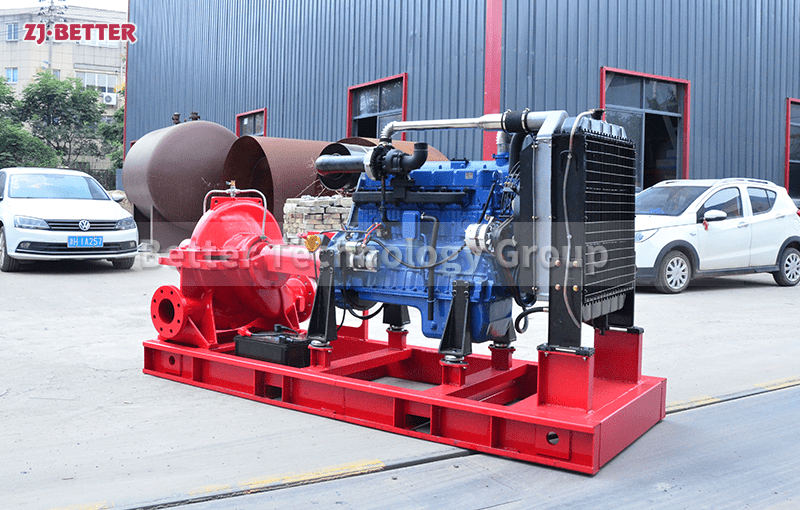

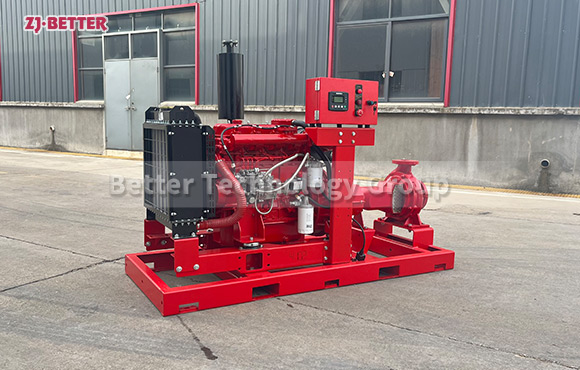

This diesel engine fire pump set adopts ISW pump.ISW series horizontal single-stage single-suction centrifugal pump is a new generation of energy saving, environment friendly horizontal centrifugal pump researched and developed by our company, which absorbs advanced technology of similar products abroad and adopts domestic general performance parameters of centrifugal pumps.

In addition, according to different operation temperatures and mediums, we developed the hot-water pump(ISWR), corrosion-resistant chemical pump(ISWH) and oil pump (ISWB). This pump enjoys excellent performance, good reliability, long operation life, reasonable construction and nice appearance, which is outstanding in the industry.