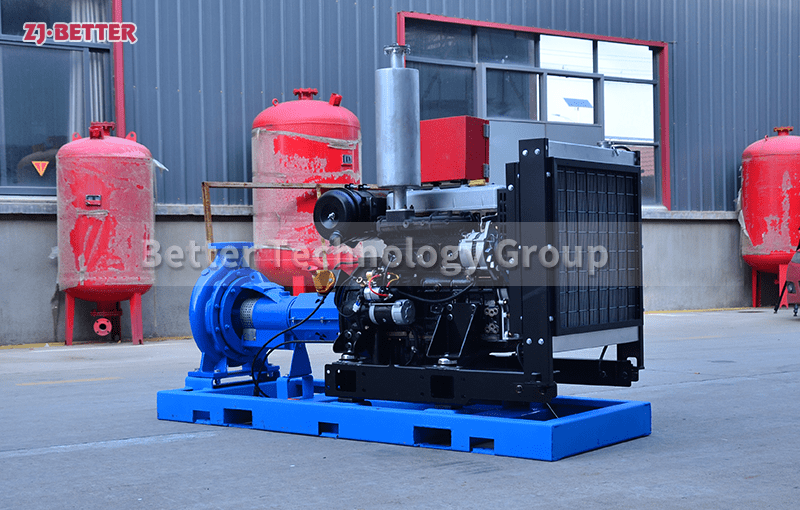

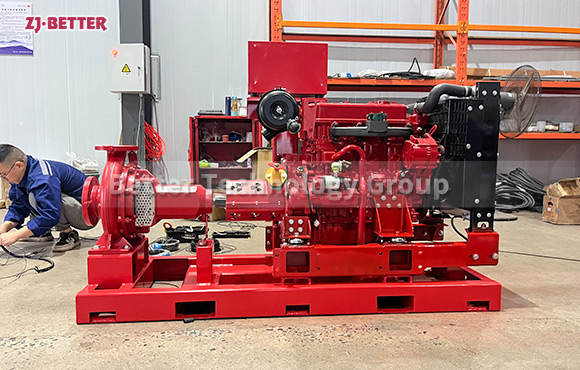

Diesel engine fire pump system is safe and reliable

Diesel engine fire pump set is a new type of fire-fighting equipment developed by our company in strict accordance with the national standard GB6245-98 “Fire Pump Performance Requirements and Test Methods” and the American Fire Protection Association standard NEPA20 “Installation of Centrifugal Fire Pumps” and other standards (hereinafter referred to as equipment ), this series of equipment can be divided into three sub-series, XBC-IS, XBC-S, XBC-D, etc. The equipment has a wide range of pressure and flow, and its application can almost meet various occasions required by fire protection.

Diesel engine fire pump unit is installed together with electrical instruments and other equipment to form a complete combination, which has complete functions, high degree of automation, compact structure, automatic fault alarm and receiving start signal, completes the start-up procedure by itself, and can quickly put into full-load operation. The unit can be equipped with shock absorbers, rubber flexible joints, and bellows mufflers for exhaust ports. In case of insufficient fuel, low battery voltage, high lubricating oil temperature, overspeed, etc., an alarm device is equipped, and a heating device is also provided to ensure that the diesel engine starts in a low temperature environment. The whole system is safe, reliable and easy to use.