Diesel engine fire pump unit is a kind of pump equipment that is widely used in fire protection

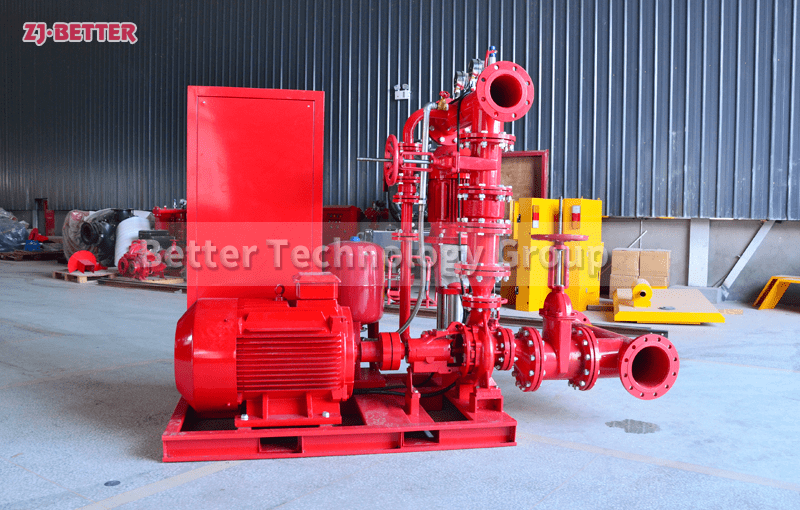

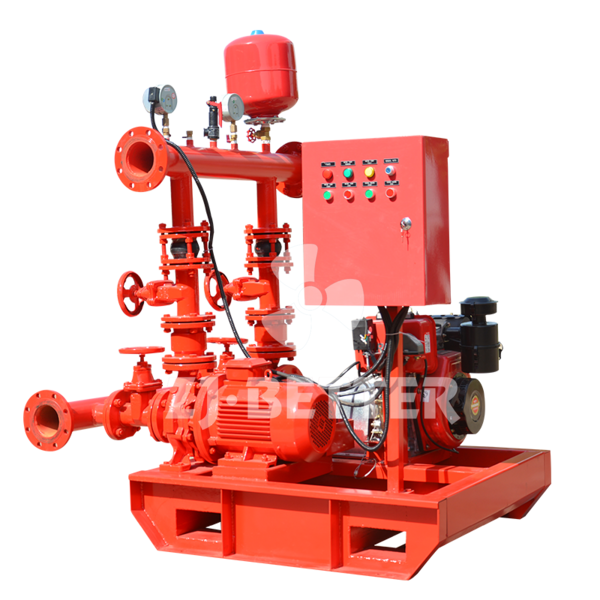

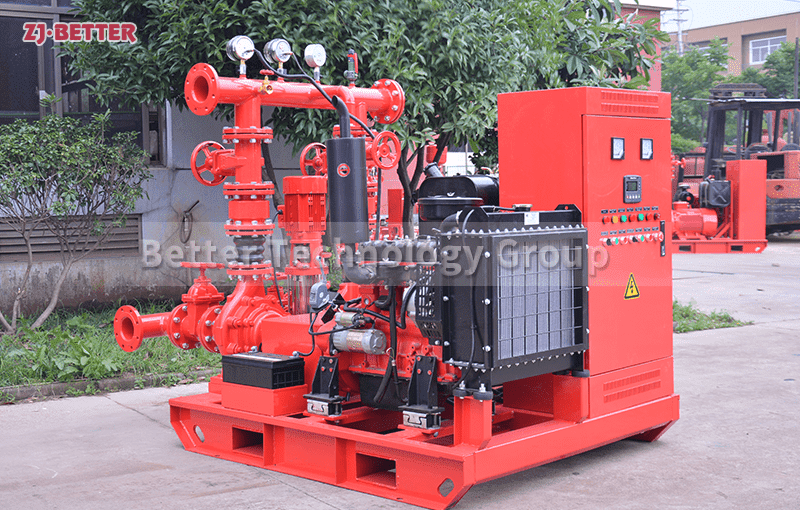

Diesel engine fire pump unit is a kind of pump equipment that is widely used in fire protection, and it is more suitable for mobile work in fire pumps. In fact, it is driven by a diesel engine connected to the pump head of the fire pump. Compared with motor drive, it can be used in the field, mines, and places lacking power supply. It is also called a diesel engine pump or a diesel engine fire pump unit.

The diesel engine-powered water pump of the fire pump set is composed of horizontal centrifugal pumps, diesel engines, electrical instruments and other equipment, which are tightly installed on a common chassis, and connected with the electric control box through control lines and signal lines. The complete set of water supply equipment for diesel engines can be used in various enterprises. The production of automatic/manual water supply system can also be used for fire water supply and occasions with special requirements.