Diesel engine fire pump unit obtained UL certification

The biggest difference between the diesel engine fire pump and the electric fire pump is that it has its own independent power supply system, which can ensure the normal operation of the project without power supply or power supply. helper.

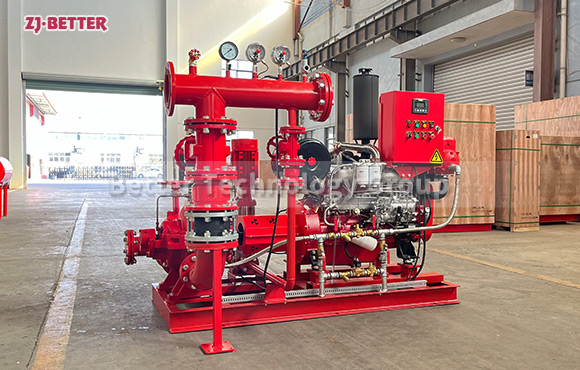

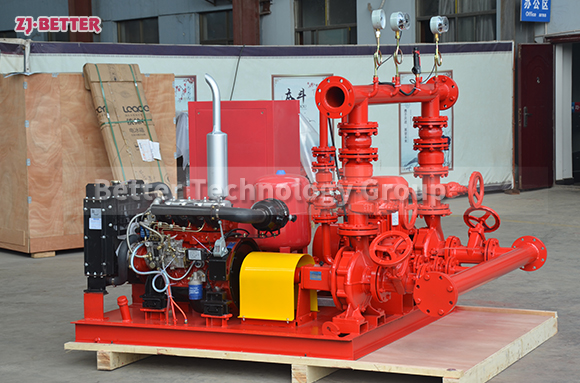

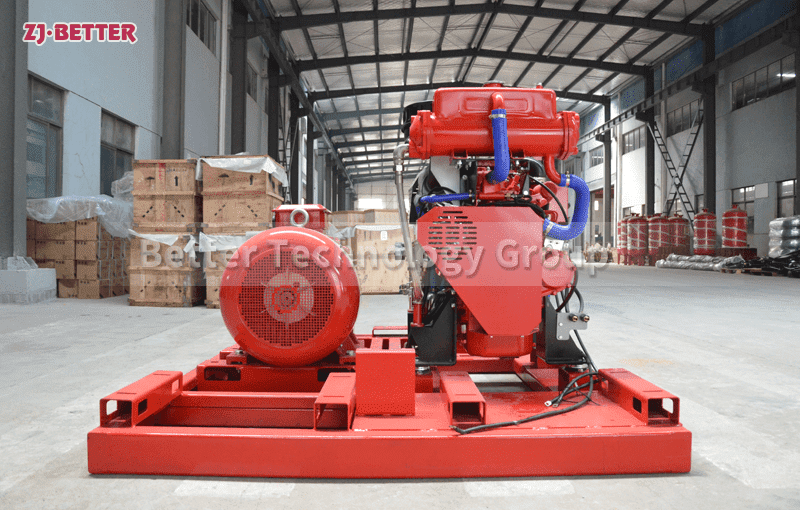

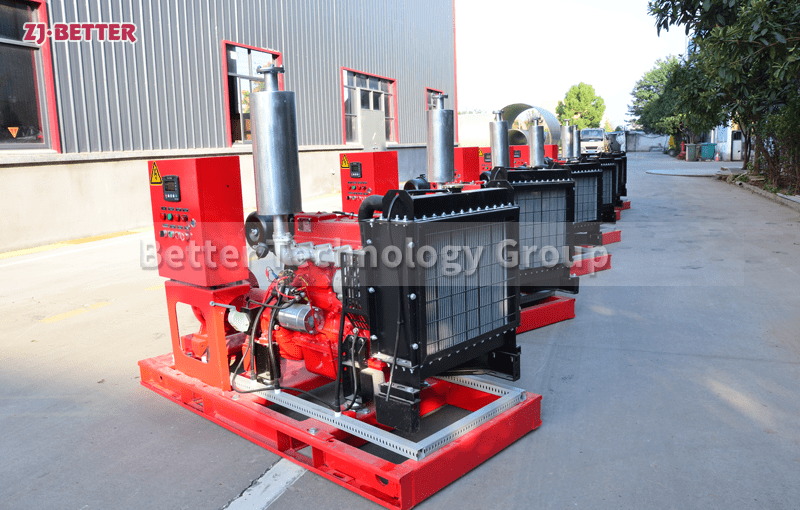

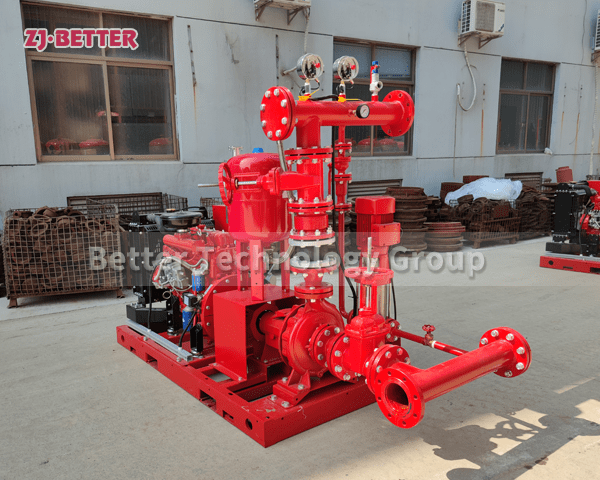

Structurally, the diesel engine fire pump is mainly composed of diesel engine, fire pump, connection device, fuel tank, radiator, battery, intelligent automatic control panel and so on. And at present, the diesel engine fire pumps are all equipped with the time limit automation function of the control cabinet. The start and operation of the diesel engine completely rely on the traditional operation mode, and realize the functions of remote control, automatic start, ultra-low voltage start and automatic alarm.

In terms of industry applications. Diesel engine fire pumps are widely used in emergency water supply for large-scale projects such as high-rise buildings, steel plants, chemical plants, hotels, and water works.

We can start with the basic structure of the diesel engine fire pump unit, and focus on whether the flow rate of the fire pump and the parameters of the pump meet the requirements. At the same time, with reference to the FM/UL certification standards of the United States, more targeted and clear requirements are put forward for the design and selection of fire pumps in my country, so that there is evidence to rely on during the selection and testing of fire pumps. The fire pump products of Better Technology Group Co., Ltd. have both UL and FM, the two highest fire certifications in the world, and their products are widely praised by the market.