Diesel engine fire pumps are relatively common in life

Diesel engine fire pumps are relatively common in life, and their performance requirements are relatively high. In normal use, more attention must be paid to maintenance to prolong the service life of the pump. Because diesel fire pumps are not omnipotent, there will be some problems in daily use, so when choosing equipment, we must pay attention to whether the quality of the equipment has reached the national standard. As fire equipment, all kinds of equipment must be Ensure performance, avoid affecting use in disasters, and delay rescue.

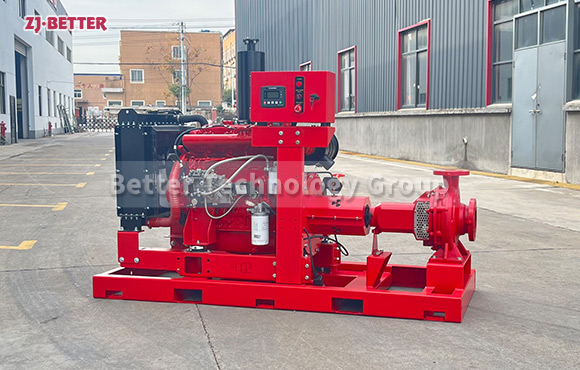

Main features of diesel engine fire pump:

1. Automatic start: After the diesel water pump diesel generator set receives a safety accident/pipeline network pressure/power failure/or other starting signal, it can automatically start within 15 seconds and operate under load;

2. Automatic charging: the battery can be automatically charged by using the working voltage or the diesel engine battery charging motor to ensure the successful start of the diesel generator set;

3. Fully automatic alarm: automatic alarm maintenance for difficult problems such as low air pressure and high temperature of the diesel engine, alarm and shutdown when the speed is limited;

4. Fully automatic heating: make the diesel engine in the state of heating engine embedded parts, to ensure emergency work;

5. Data transmission mode: 360kw or less diesel water pump diesel generator set adopts professional and leading diesel engine and centrifugal water pump to connect professional ability immediately through flexible coupling, which reduces problems and greatly shortens the start-up time of diesel generator set shortened, improving the reliability and emergency characteristics of diesel generator sets;

6. Consumers can also specify to set other alarm outputs;

7. It has the functions of inspection, remote signaling and control panel.

.jpg)