Diesel engine fire pumps are widely used in fire fighting

As a fixed firefighting equipment, diesel engine fire pumps are widely used in firefighting and shunting operations, especially when there is no power supply or no power supply (main power supply).

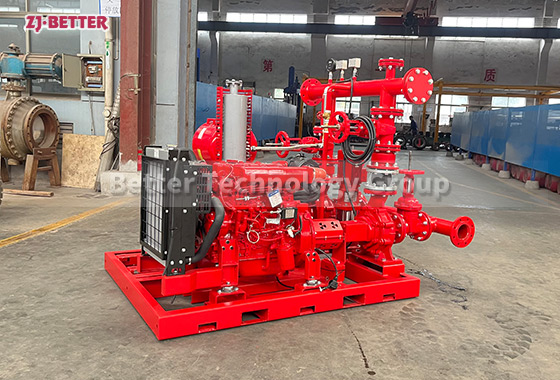

Diesel fire pumps can also be equipped with other diesel engines as power engines according to user needs. It is mainly composed of diesel engine, fire pump, connection device, fuel tank, radiator, battery, intelligent self-control panel, etc. The crankshaft of diesel engine fire pump has high overall rigidity, high strength and high torque transmission efficiency. Adopt international advanced technology, sliding bearing, plate-fin cooler, upper heat exchanger, rotary oil filter, double cooling system. Diesel engine fire pump performance, smoke and noise indicators meet national standards.

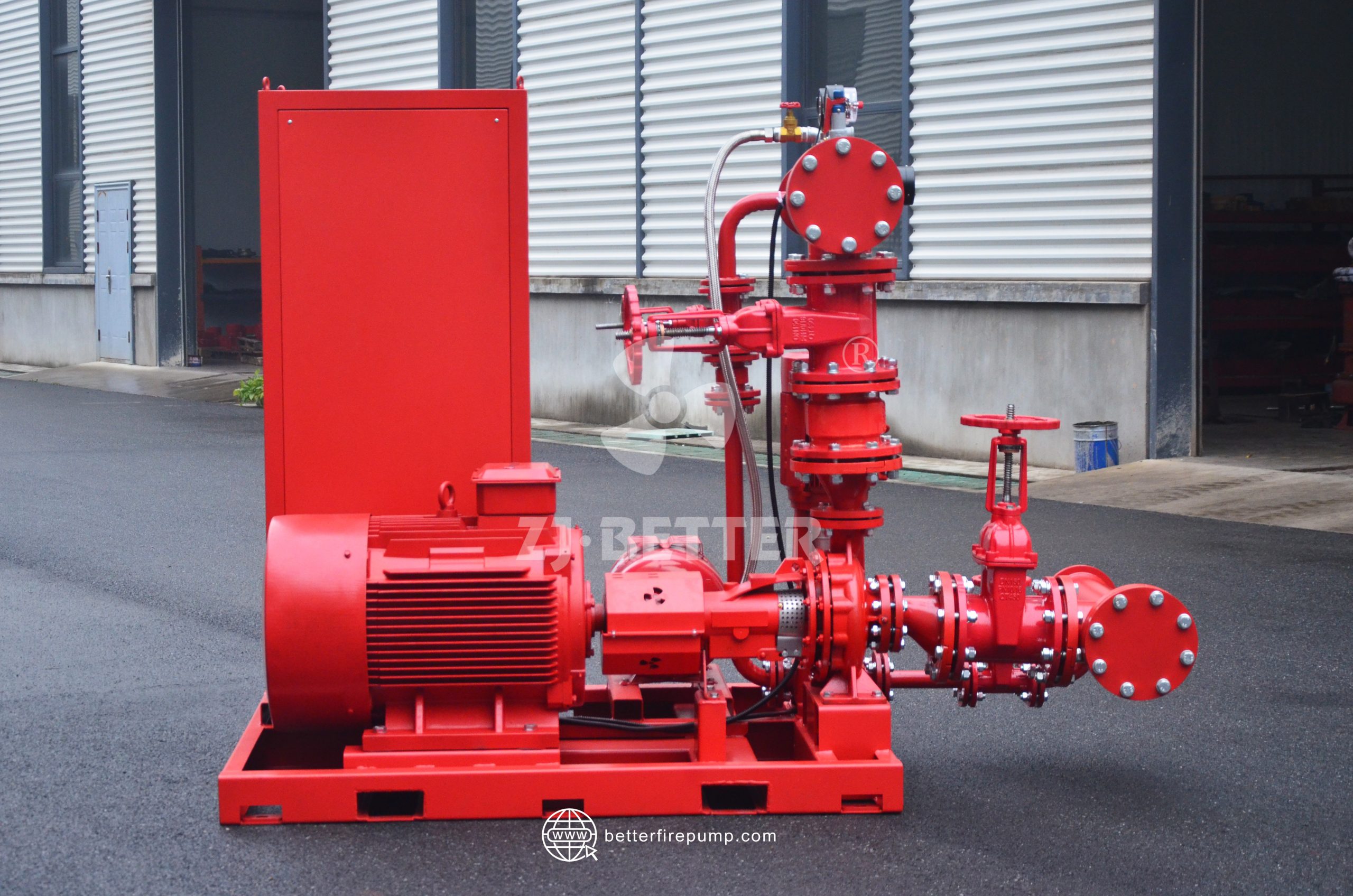

XBC diesel engine fire pump set is a new product independently developed and produced according to the standard requirements of GB6245-2006 “Fire Pump” and the market demand and use characteristics of domestic building fire pumps. This series of fire pumps has high efficiency, long operating life, and high reliability (there is no fault of seizure after being stopped for a long time). The performance of the product conforms to the performance requirements and experimental methods of GB6245-2006 “Fire Pump”. Under the premise of meeting the fire protection conditions, the requirements of the living and production water supply conditions are taken into account. The products can be used not only in independent fire water supply systems, but also in fire protection and domestic shared water supply systems, as well as in construction, municipal, industrial and mining, water supply and drainage, ships, field operations and other occasions. The advantage is that the electric fire pump cannot be started after a sudden power failure in the power system, and the diesel engine fire pump is automatically started and put into emergency water supply.