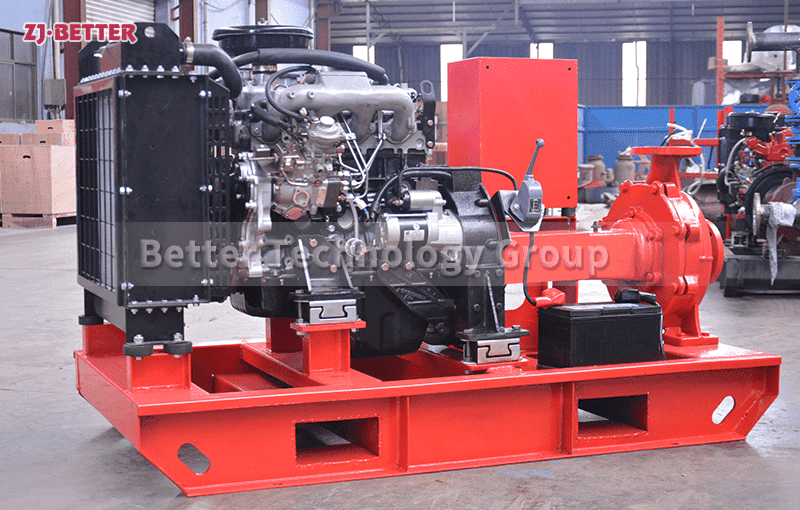

Diesel engine Fire Water Pump Supplier

Application

Hotels, hospitals, gymnasium and other public places;

Chemical, oil refining, metallurgy, energy, medicine and military and other enterprises;

Shopping malls, similar to Wanda complex;

Office buildings, high-end residential buildings;

Environmental and Working Conditions

Ambient temperature:

Ambient temperature range 4℃-40℃.

Working to improve the ambient temperature every 5℃, its power decreased by 1%(to 25℃ as the base);

Altitude:

Reference elevation 91.4m, the reference atmospheric pressure is 100KPa;

If the work to an altitude of over 1000m, reference should be corrected GB1105 1-1987 diesel engine power, you can consult the specific technical department;

Relative humidity ≤80% (20℃), outdoor allow 90% (when installed outdoors in the order presented, you can choose to configure the outdoor structure, protection class IP55).

The Scope of Work

Water pressure: 0. 2-2.5MPa (20~250 meters);

Flow range: 5-1200L/S

Power: 3kW~2000kW;

Speed range: 1500~3200r/min

Permissible media: Drinking water, chilled water, fire water, and other impurities without abrasive or long-fiber impurities and no chemical or mechanical pump for corrosive media.

Allow the maximum medium temperature 70℃, the maximum ambient temperature of 40℃;

Maximum allowable working pressure of 1.6MPa, the maximum inlet pressure 0.6MPa.