Home » Diesel engine fire pump » Diesel Engine Self-Priming Pump with High Efficency

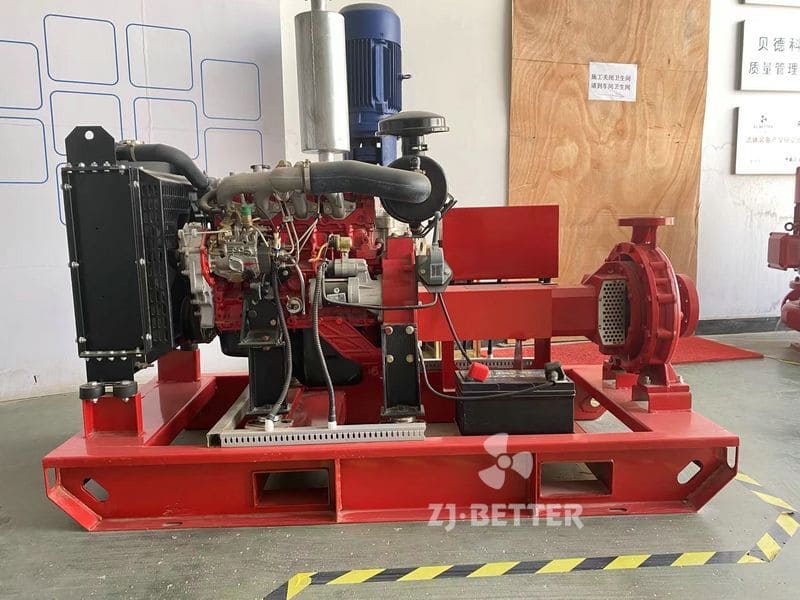

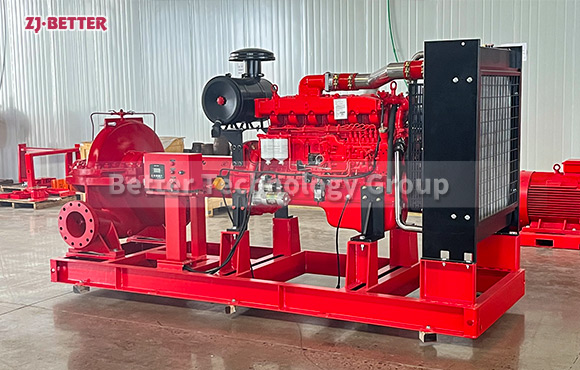

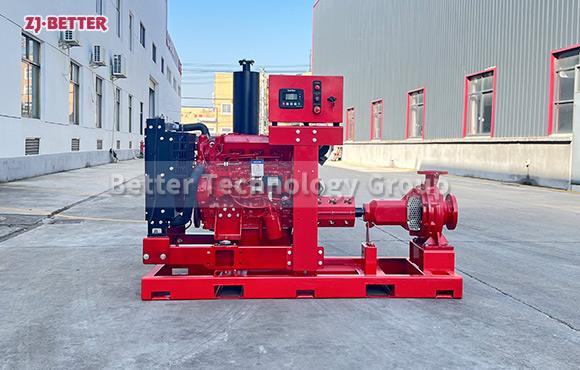

Diesel Engine Self-Priming Pump with High Efficency

A diesel engine self-priming pump with high efficiency is a type of pump that combines the advantages of a diesel engine power source, self-priming capability, and a design that maximizes pumping efficiency. This type of pump is commonly used in various applications where a reliable and efficient water transfer is required, particularly in scenarios where the pump needs to handle large volumes of water and deal with air or gas entrained in the fluid.

Contact US

Get Price

Share:

Content

- Diesel Engine Power Source: The pump is driven by a diesel engine, providing a dependable and independent power supply. Diesel engines are known for their durability, fuel efficiency, and the ability to run for extended periods without electricity, making them suitable for remote or emergency situations.

- Self-Priming Capability: One of the essential features of this pump is its self-priming ability. Self-priming pumps can evacuate air from the suction line and prime themselves without the need for manual priming. This makes initial setup and restarts after maintenance or power interruptions much more convenient and efficient.

- High Efficiency Design: These pumps are designed for optimal hydraulic efficiency, with well-designed impellers, casings, and volutes to minimize friction losses and maximize water flow. High efficiency reduces energy consumption, resulting in cost savings and reduced environmental impact.

- Heavy-Duty Construction: Diesel engine self-priming pumps are typically built with robust and durable materials to withstand demanding operating conditions, such as rugged construction sites or challenging environmental factors.

- Large Flow Capacity: The pump is capable of handling large volumes of water, making it suitable for applications such as dewatering, irrigation, flood control, and firefighting.

- Multiple Sizes and Configurations: These pumps come in various sizes and configurations to meet specific application requirements. Different models offer different flow rates, pressure capabilities, and port sizes to cater to a wide range of pumping needs.

- Fuel Efficiency: The diesel engine is engineered to be fuel-efficient, maximizing the water pumping output for each unit of fuel consumed. This is crucial in applications where extended operation times are expected.

- Automatic Controls and Safety Features: Diesel engine self-priming pumps often come equipped with automatic controls, monitoring systems, and safety features to ensure reliable and safe operation. These features may include low oil pressure shutdown, over-temperature protection, and monitoring of pump parameters.

- Ease of Mobility: Many of these pumps are designed with portability in mind, featuring skids or wheels for easy movement and transportation to different job sites.

- Low Maintenance Requirements: The pumps are engineered for low maintenance needs, with user-friendly designs that facilitate quick and simple maintenance tasks.

Inquiry

More Diesel engine fire pump