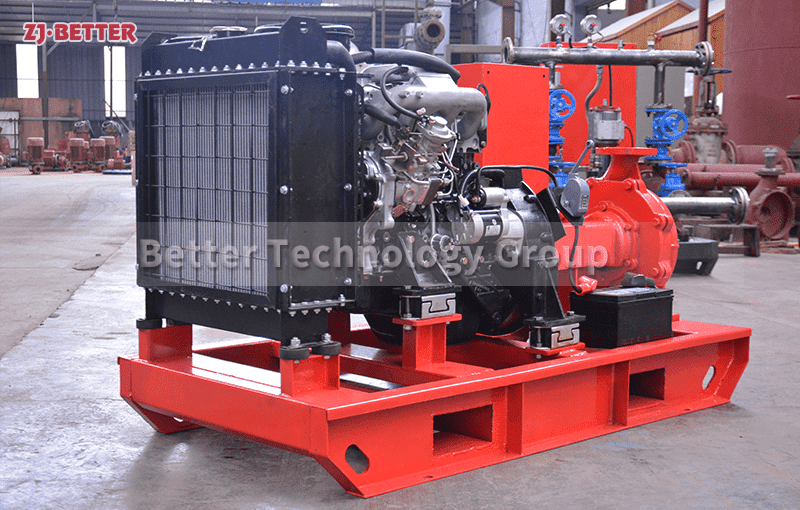

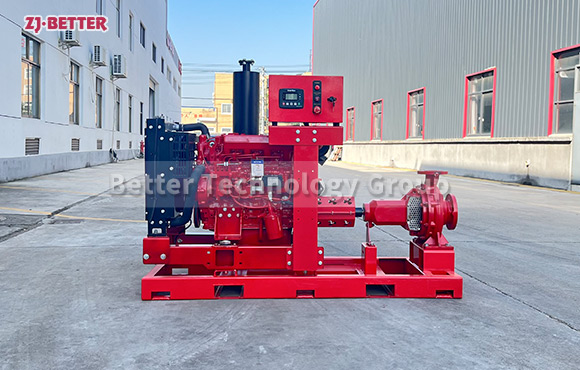

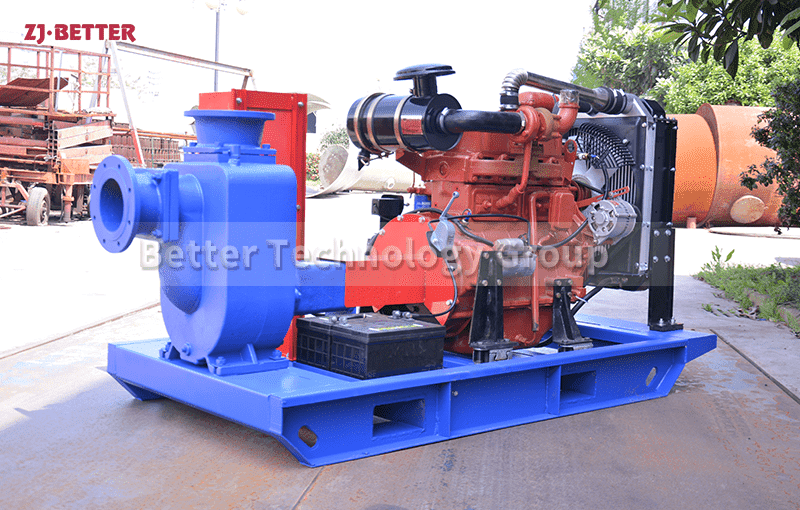

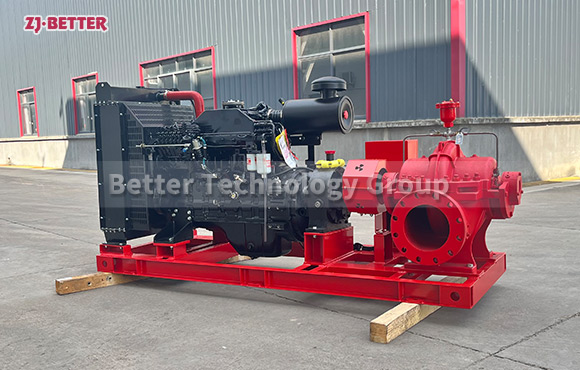

Diesel fire pump can be used in various occasions required for fire protection

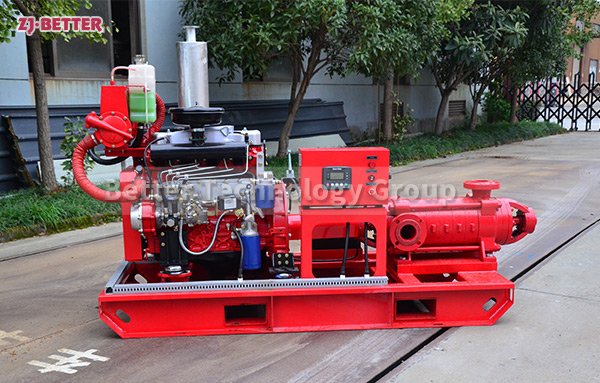

XBC series diesel engine fire pump is a new type of fire fighting equipment developed on the basis of supporting fire pumps (single-stage single-suction type, single-stage double-suction type, segmented multi-stage type), and can be divided into several series. The equipment has a wide pressure and temperature range and can be used in almost every occasion required for fire protection. The diesel engine matched with this equipment is an excellent domestic or imported product, which has the characteristics of good starting performance, strong overload capacity and compact structure. , easy to maintain and use, high degree of automation.

Diesel engine fire pump start function:

1. Manual start function: manual and automatic interlocking can be completed through the changeover switch, and the manual start function can be realized:

2. Automatic manual function: three starts are allowed. If the three starts are unsuccessful, a “start failure alarm” will be issued and the starting state will be automatically exited; after one successful start, the time from starting to rated load is 5-10-15S (depending on the capacity of the unit) );

3. Emergency manual direct start function: when the automatic control device fails, the emergency manual direct start function can be realized.