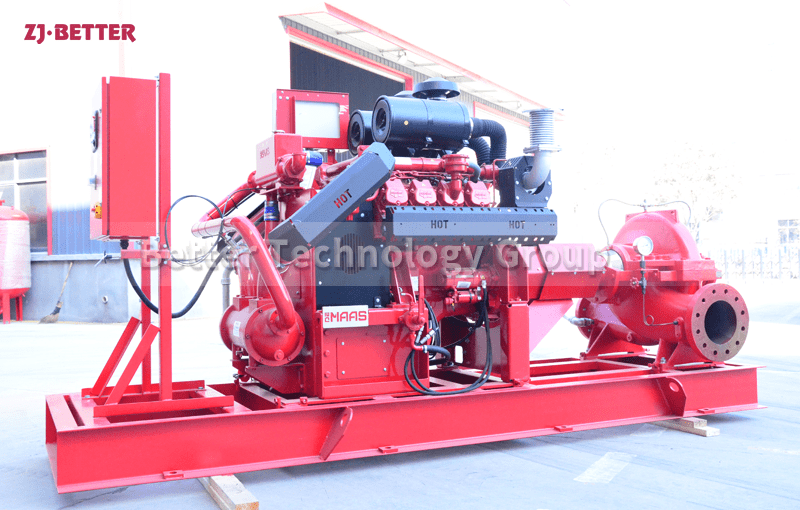

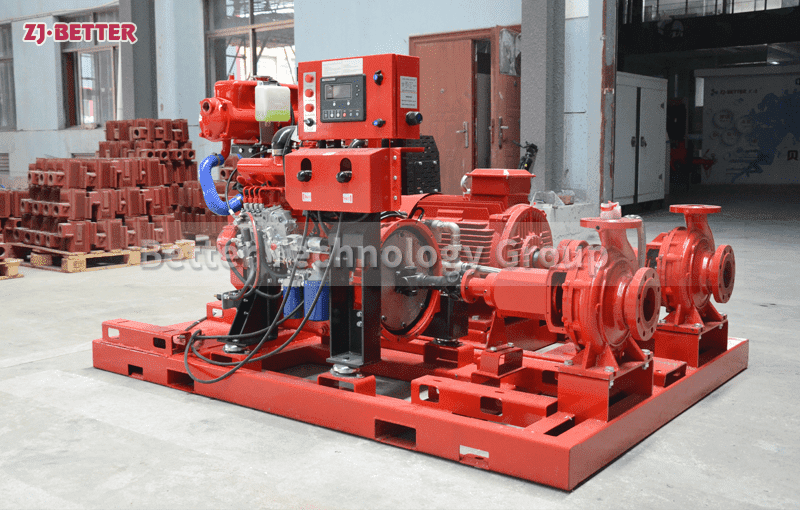

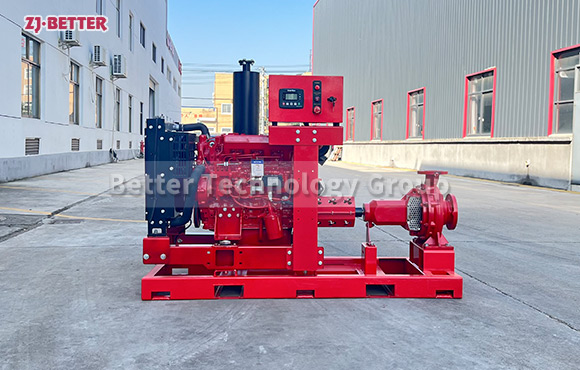

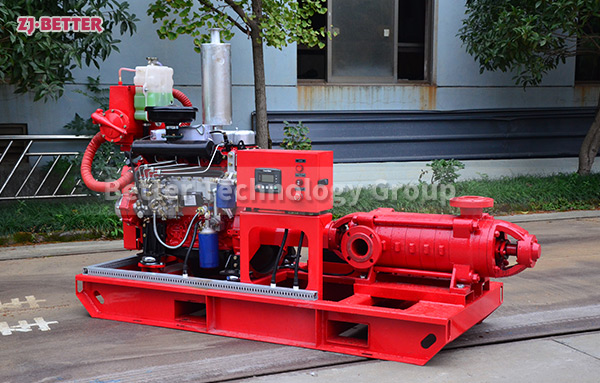

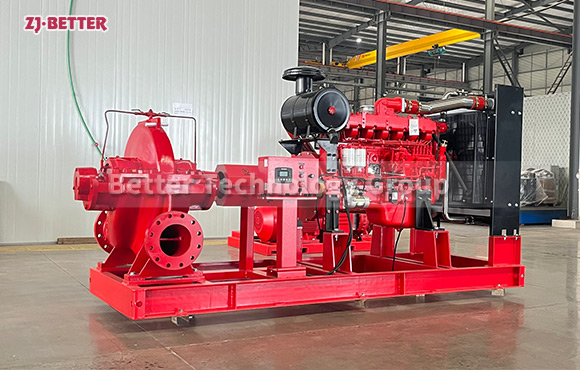

Diesel fire pump play a decisive role in firefighting industry

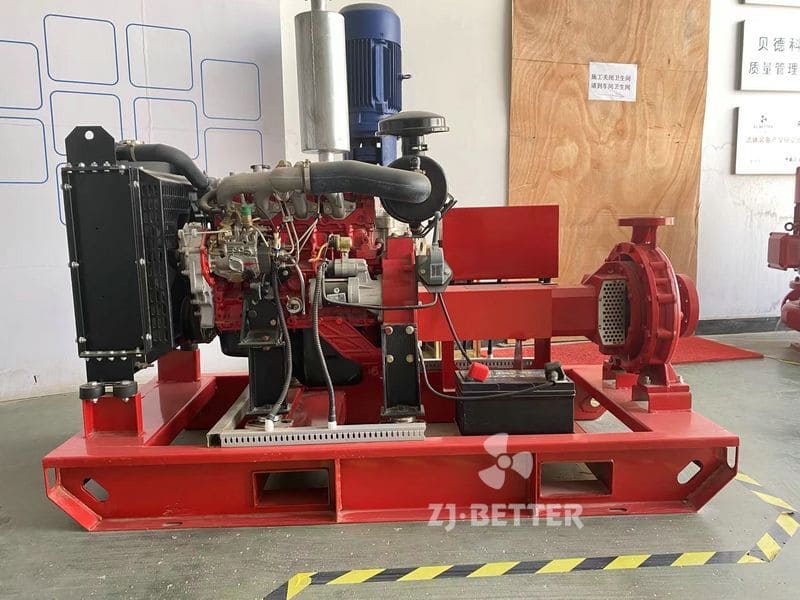

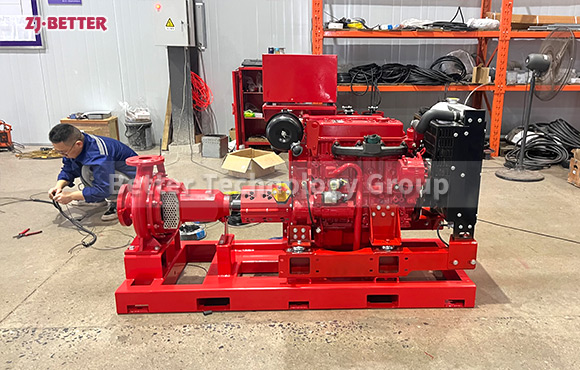

The diesel engine fire pump is mainly used for ship emergency fire protection, and is also applicable to industrial and mining enterprises, port terminals, warehouse yards and other places.

The diesel engine fire pump is mainly used for ship emergency fire protection, and is also applicable to industrial and mining enterprises, port terminals, warehouse yards and other places.

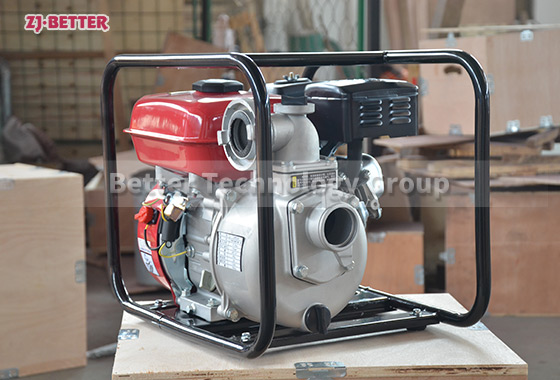

The diesel engine fire pump has the advantages of light weight, small size, flexible movement, quick start, fast water discharge time, large fuel tank capacity, corrosion resistance, reliable use and convenient maintenance. It can be automatically started and self-primed, and can be self-priming after dry running. Heavy duty pump bearings – long life; other parts are made of high quality copper and stainless steel or custom made. The high-efficiency open impeller design of the diesel fire pump can handle large solids and abrasive materials while maintaining high flow rates, and large-capacity air treatment can be used for more“well point precipitation projects”.