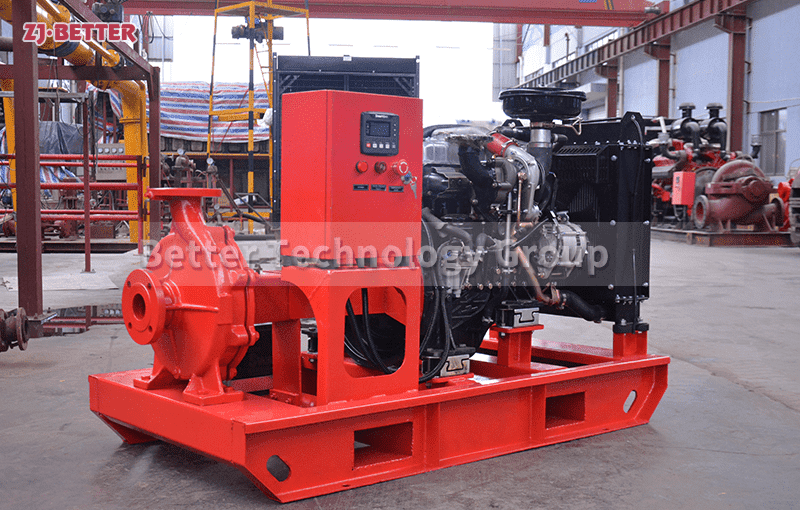

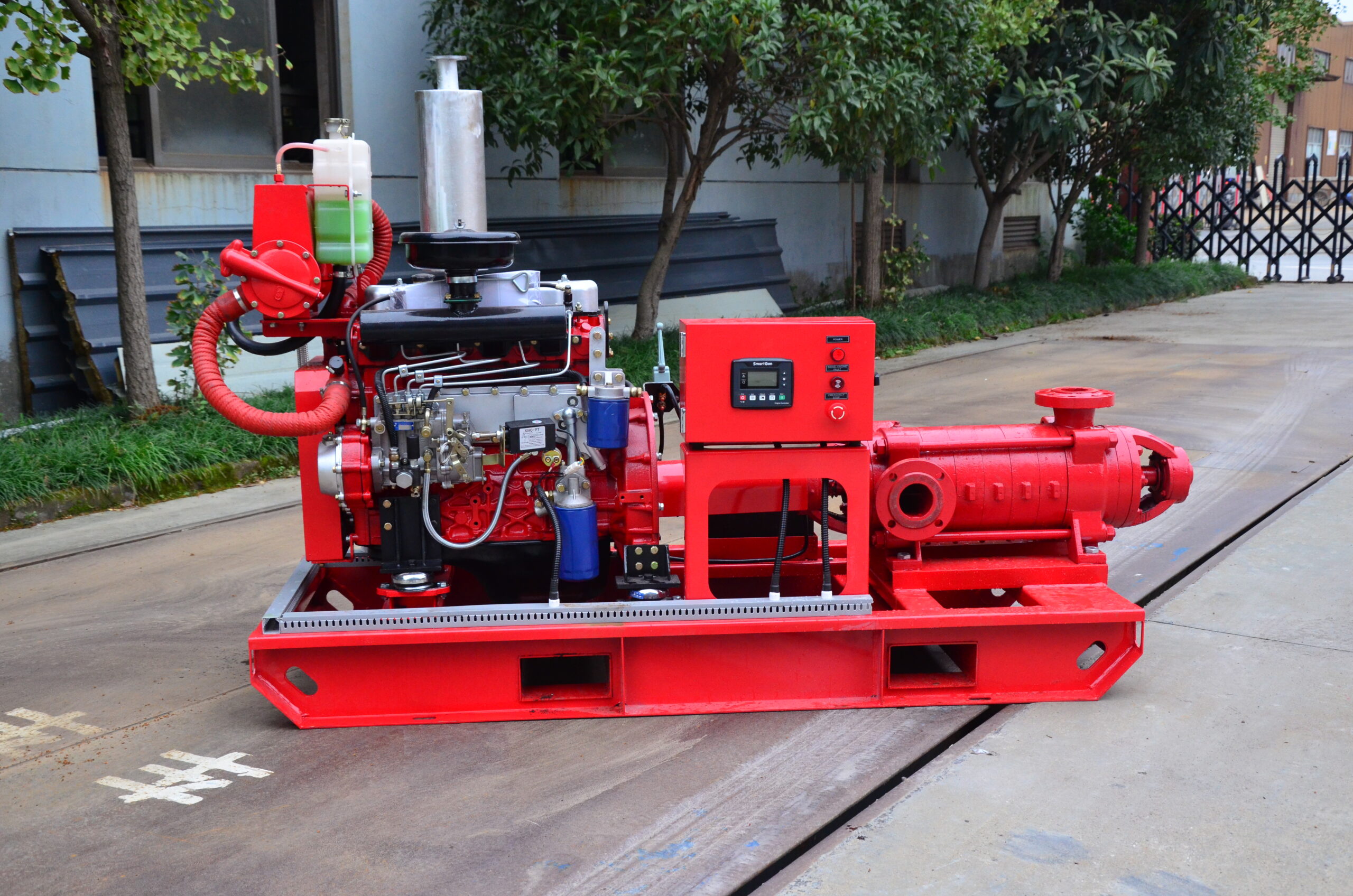

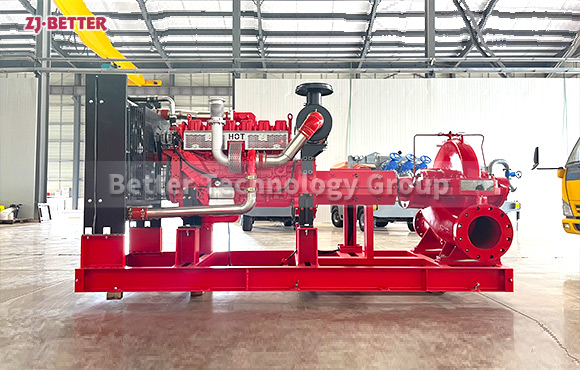

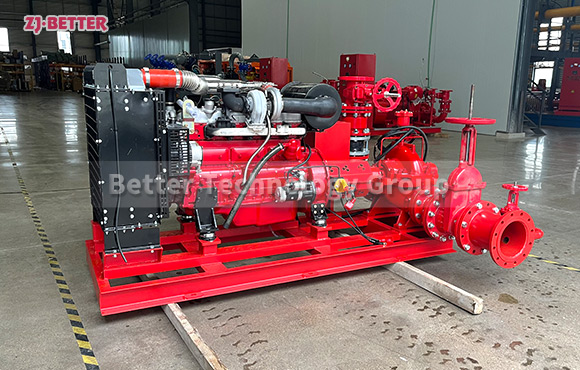

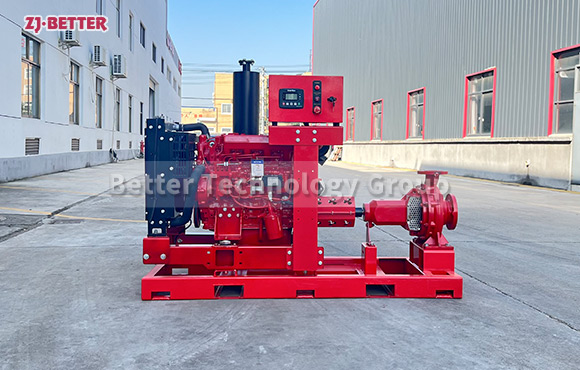

Diesel fire pump set with automatic control cabinet

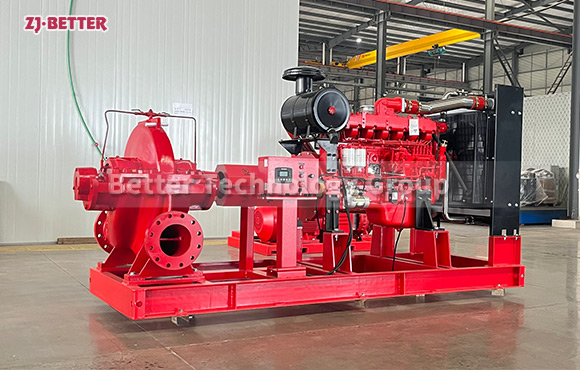

Diesel engine fire pump can be used in fire water supply in warehouses, docks, airports and other occasions. We usually choose the appropriate diesel engine fire pump model and application according to the head, flow, power, medium properties, and required materials provided by the user. In order to avoid mistakes, the loss caused by the installation environment will be comprehensively considered to ensure stable and reliable efficiency.

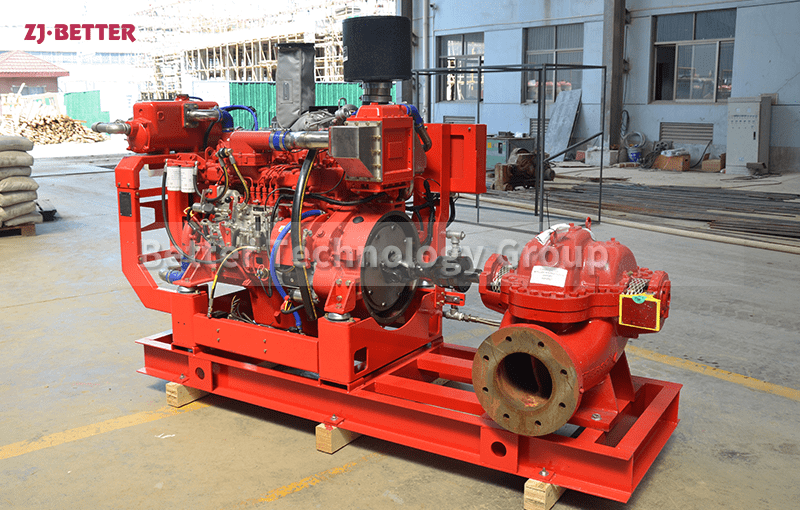

According to the technical information of diesel engine fire pump, diesel engine fire pump has been widely used in environmental protection, water treatment, fire protection and other departments to pump various liquids. It is an ideal pump to create civilized workshops and factories without leakage and pollution. In general, there are three common control methods for diesel engine fire pumps:

1. Manual control: The diesel engine fire pump is manually pressed by the control panel button, and the operation process is automatically completed by the preset program.

2. Automatic control: When the equipment is affected by fire/pipe pressure or other automatic control signals, the response starts/stops.

3. Remote control: The computer realizes remote monitoring, remote control, remote communication and remote adjustment through the communication network.