Diesel Fire Pump with Silent Enclosure: Power Meets Quiet Operation

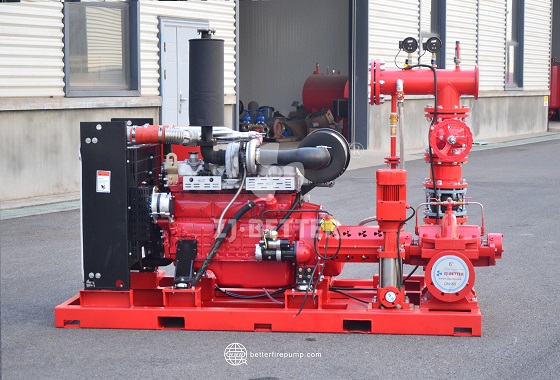

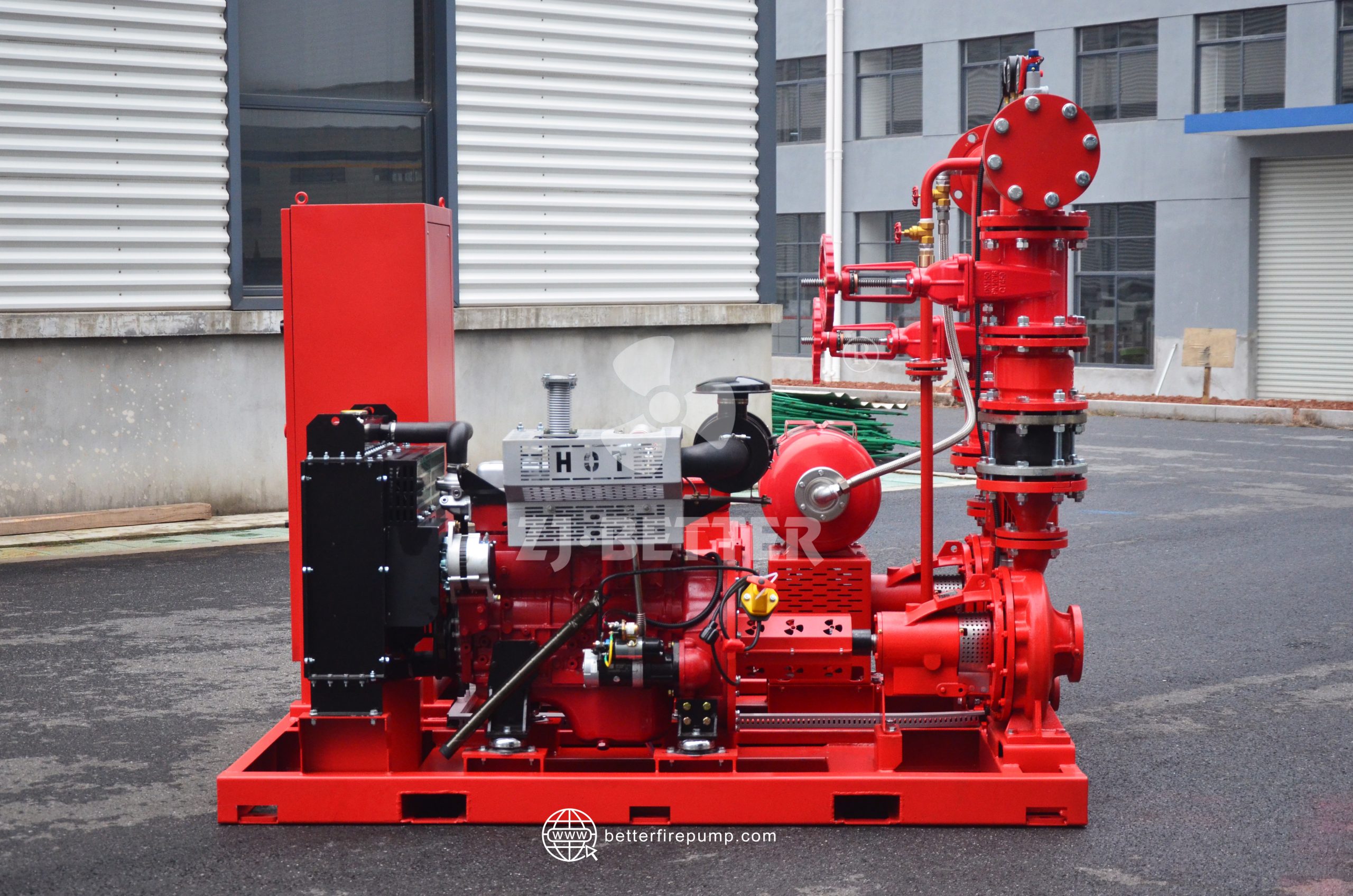

In emergency fire protection systems, balancing noise control and power performance is often a challenge. The diesel fire pump with silent enclosure perfectly solves this issue by delivering high output power while maintaining quiet operation. It features a premium diesel engine paired with a high-efficiency fire pump, all housed in a fully enclosed soundproof cabinet. This design significantly reduces operational noise, making it ideal for noise-sensitive locations such as hospitals, shopping malls, subways, and residential areas.

The unit boasts a compact structure and user-friendly design, equipped with an intelligent control panel that enables automatic start-stop, remote monitoring, and self-diagnostic functions. Its heat-resistant, shockproof, waterproof, and dustproof features make it adaptable to a wide range of harsh environments, providing users with a safer, more reliable, and more efficient fire pump solution.

With extensive experience in the fire pump industry, the company offers comprehensive, high-quality fire protection solutions tailored to global markets. The product portfolio includes electric fire pump sets, diesel engine fire pumps, dual power control panels, pressure maintenance systems, intelligent control integrations, and fully assembled NFPA20 and UL/FM certified units. These systems are designed to meet stringent fire safety requirements across a wide range of industries.

Each product is engineered with a strong focus on performance and system reliability. Every unit undergoes rigorous testing, including hydrostatic pressure, noise level, vibration tolerance, and control system stability, to ensure fast and steady operation in emergency scenarios. By combining international advanced technology with efficient local manufacturing, the company has significantly improved energy efficiency, operational lifespan, and user convenience of its equipment.

The company’s solutions are widely used in high-rise buildings, industrial complexes, tunnels and subways, petrochemical warehouses, power plants, airports, ports, and municipal infrastructure. Proven track records from numerous major projects have solidified the company’s reputation for reliability, durability, and adaptability in challenging environments.

Furthermore, a skilled technical team and a well-established after-sales network ensure complete support from initial consultation to system integration and ongoing maintenance. Whether for standard applications or complex custom projects, the company delivers fast, efficient, and dependable solutions, living up to the commitment that “Safety comes from expertise, and quality builds reputation.”