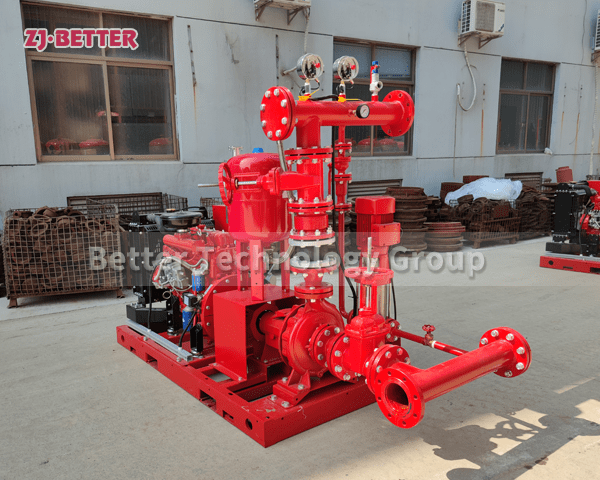

Diesel fire pumps are available as backup

The biggest difference between a diesel engine fire pump and an electric water pump is that it has its own independent power supply system—the battery. Therefore, the start-up and operation of the diesel engine fire pump can be completely separated from the mains.

The diesel engine fire pump is usually used as a backup facility, and it will only start automatically when the electric water pump fails or the power is cut off when the fire signal comes. When equipped with an ultra-low pressure pump starting device, the matching electric pump control cabinet should also be equipped with an ultra-low pressure pump starting device, and the lower limit of pump starting should have a certain pressure difference. Of course, it is also possible to design a control system that is more suitable for customer needs according to customer requirements.

Main Features of Diesel Engine Fire Pump

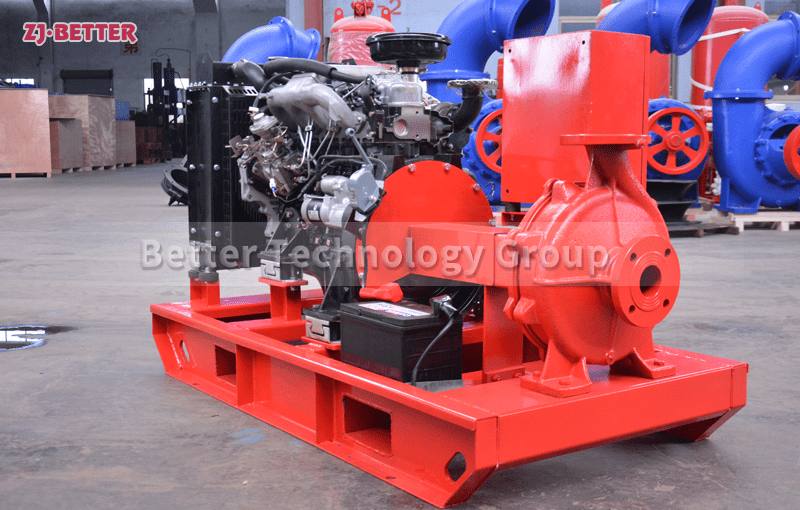

1. Automatic preheating: make the diesel engine fire pump in the standby state of the heat engine to ensure emergency work;

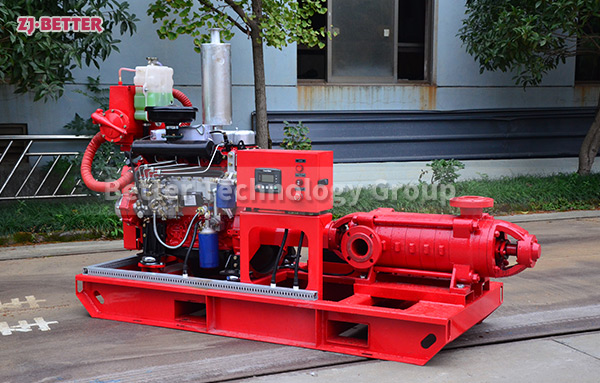

2. Direct connection type: The diesel engine and the water pump used in the diesel water pump unit below 360kw are directly connected through the elastic coupling technology, which reduces the failure points, greatly shortens the starting time of the unit, and increases the reliability and emergency performance of the unit;

3. Users can also request to set other alarm outputs;

4. Automatic start: After the diesel water pump unit receives a fire alarm/pipe network pressure/power failure/or other start signals, it can automatically start within 15 seconds and put into full-load operation;

5. Automatic charging: the battery can be automatically charged by the city electricity or diesel engine charging motor to ensure the smooth start of the unit;

6. Automatic alarm: automatic alarm protection for diesel engine low oil pressure, high water temperature and other faults, alarm and stop when over speed.