Diesel fire pumps are for large flow fire water supply

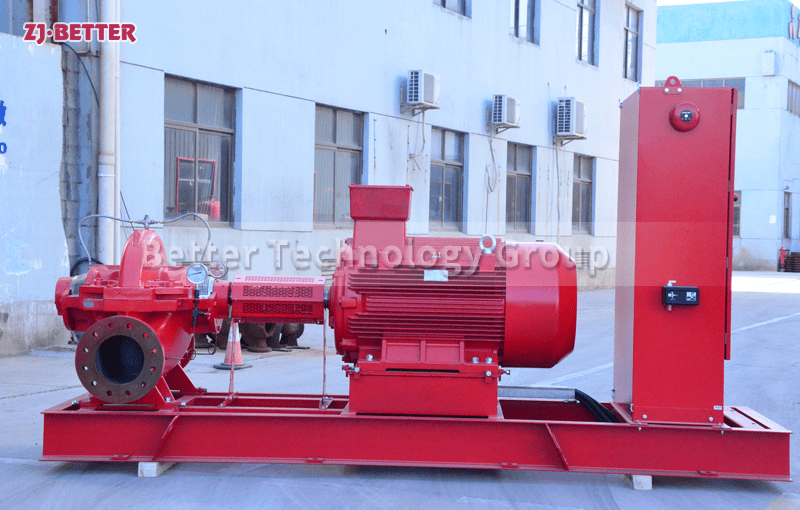

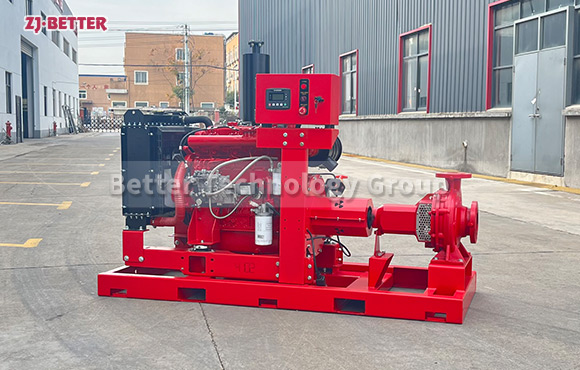

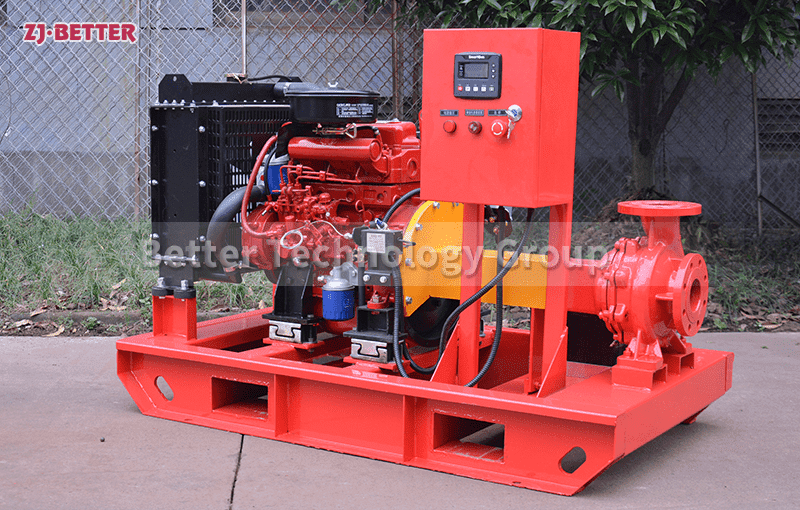

The diesel engine-powered water pump of the fire pump set is composed of horizontal centrifugal pumps, diesel engines, electrical instruments and other equipment, which are tightly installed on a common chassis, and connected with the electric control box through control lines and signal lines. The complete set of water supply equipment for diesel engines can be used in various enterprises. The production of automatic/manual water supply systems can also be used for fire water supply and occasions with special requirements.

Diesel engine fire pumps are aimed at fire water supply for large flow and high head occasions, and the diesel engine has good starting characteristics, fast starting speed, strong overload capacity, energy saving and does not need to be on standby all the time. The fire pump has complete performance and wide spectrum range. Single-stage single-suction pumps, multi-stage single-suction pumps, self-priming pumps and long-axis pumps can also be used in parallel, with a wide range of flow and pressure. Fire pumps are widely used for fire water supply in warehouses, docks, airports, petrochemical, power plants and other industrial and mining enterprises.

.jpg)