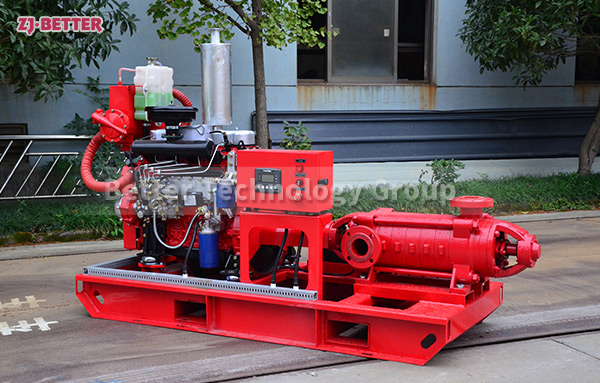

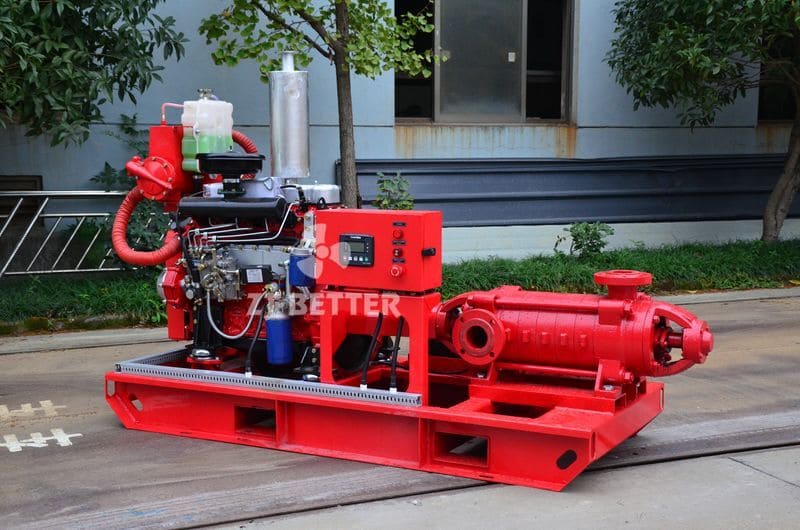

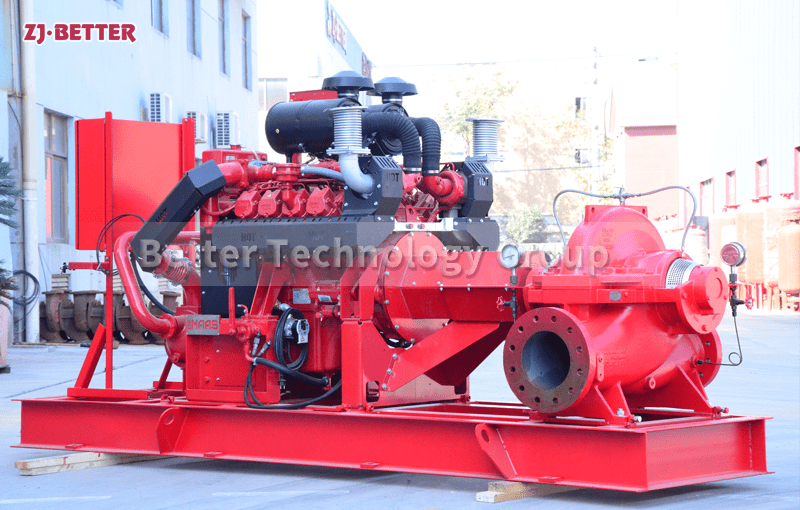

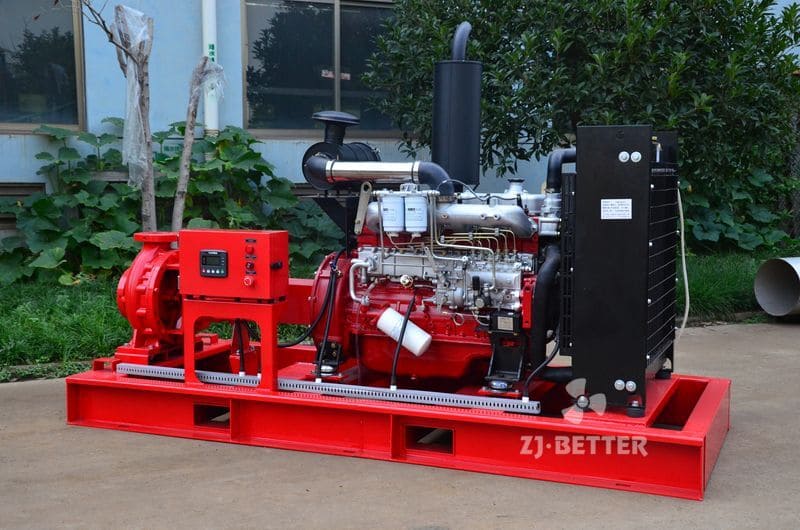

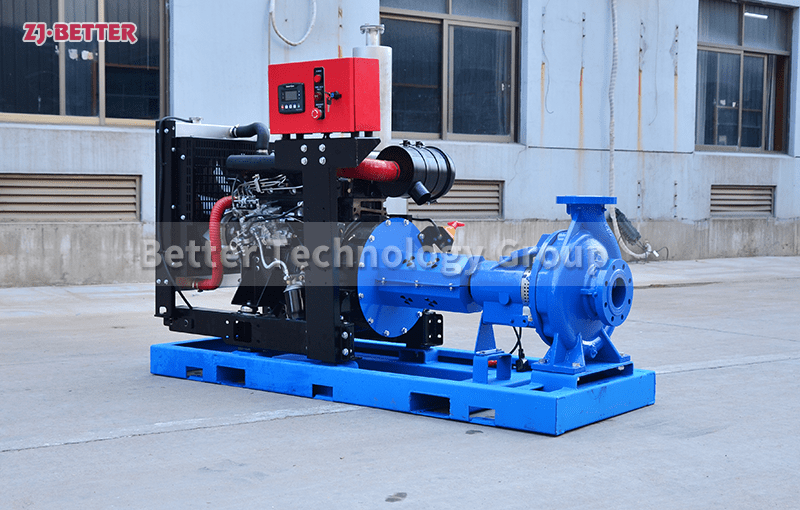

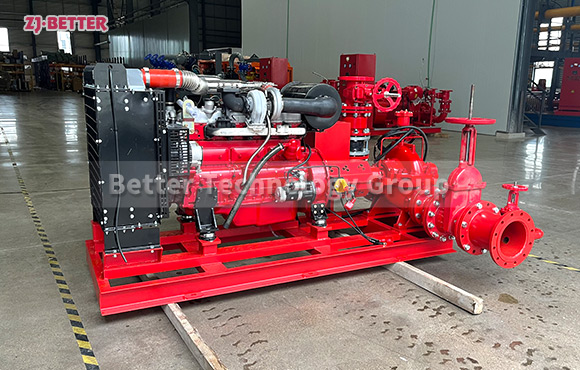

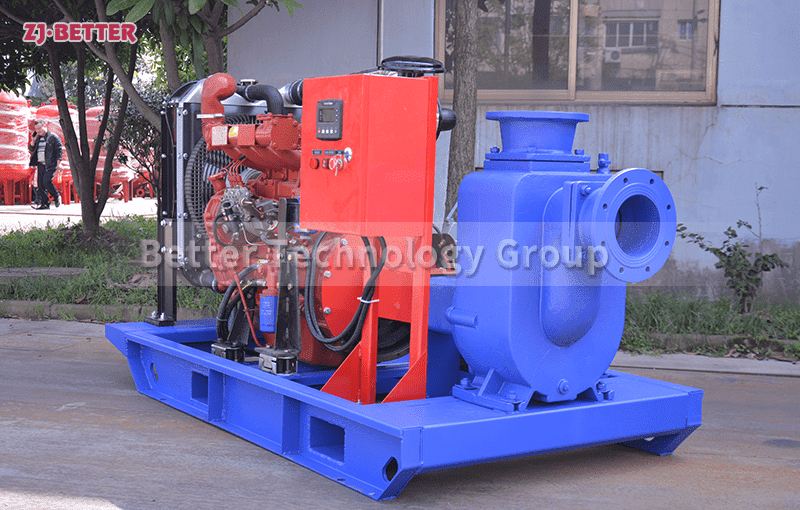

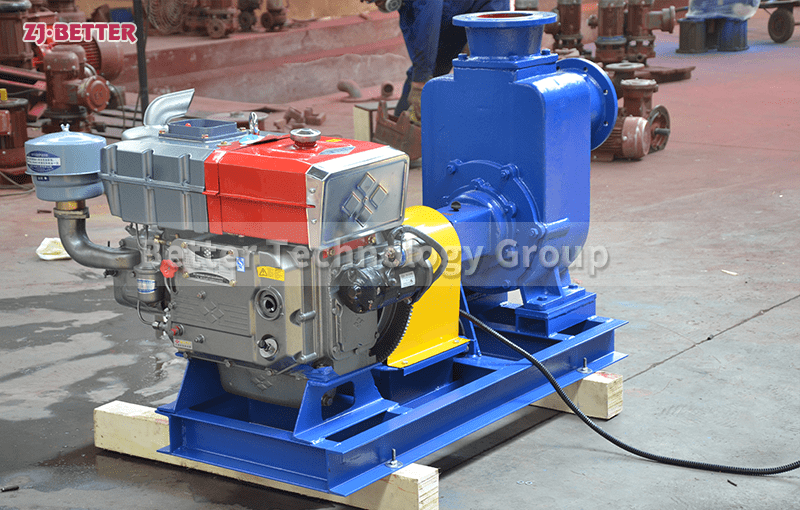

Diesel Self-Priming Pump: Efficient Energy Leader

The Single-Bar Diesel Engine Self-Priming Pump stands out as an exceptional solution designed for a variety of industrial applications. Whether it’s on construction sites, agricultural fields, or industrial production lines, this self-priming pump showcases unparalleled performance. Its powerful suction capability makes it an ideal choice for handling drainage, fluid transport, and lifting water levels. The pump’s exquisite craftsmanship and reliable design ensure stable operation in diverse environments, contributing to enhanced work efficiency. Choosing the Single-Bar Diesel Engine Self-Priming Pump means opting for a reliable and efficient solution tailored to meet the demands of your specific application scenarios.

Single-Bar Diesel Engine Self-Priming Pump excels in various industrial applications with its versatile features. This pump is specifically designed to handle drainage, fluid transport, and water lifting tasks efficiently. Its powerful self-priming capability makes it well-suited for applications in construction sites, agricultural irrigation, and industrial processes where reliable water management is crucial. The pump’s robust design ensures dependable performance, while its user-friendly features simplify operation and maintenance. Choose this self-priming pump for a dependable and efficient solution tailored to meet the specific demands of diverse applications.