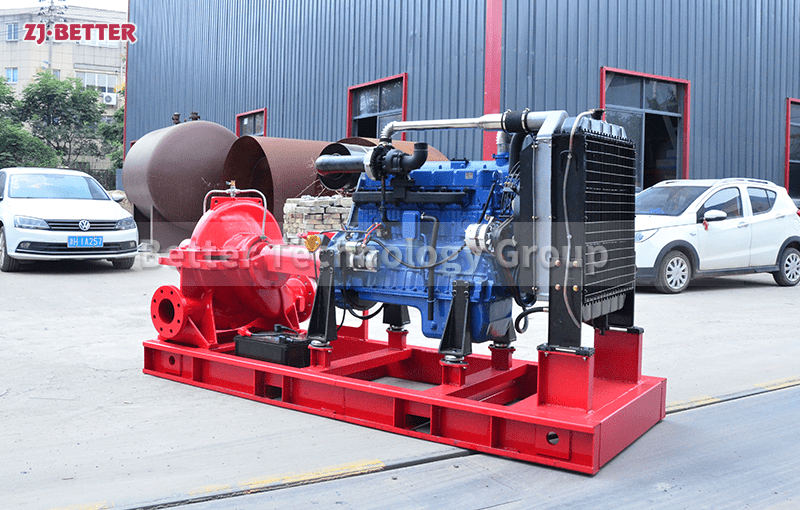

Diesel Split Case Fire Pumping Excellence

Flow:250-10000 GPM

Head:3-16 Bar

Power:11-1000 kw

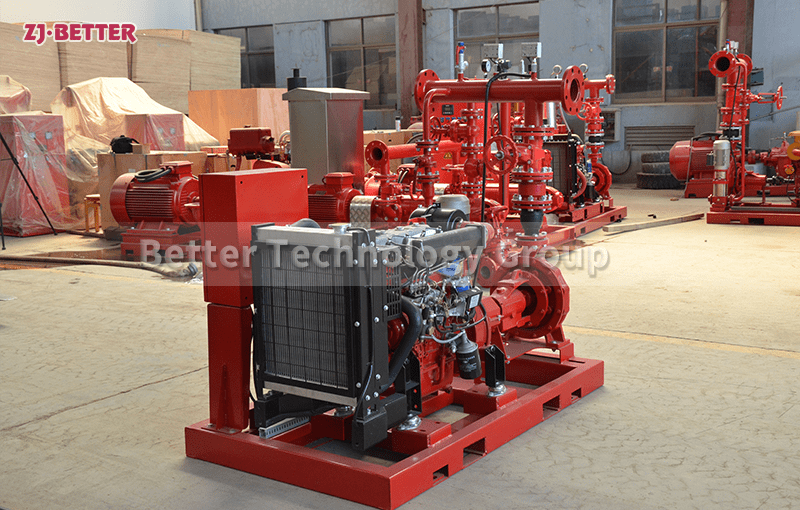

The XBC-OTS Diesel Engine Fire Pump finds wide application in various locations and buildings, including factories, commercial buildings, residential complexes, hospitals, airports, ports, and more. Whether serving as the primary firefighting water source or a backup water supply, it offers reliable support to your firefighting equipment and systems.

Equipment Features:

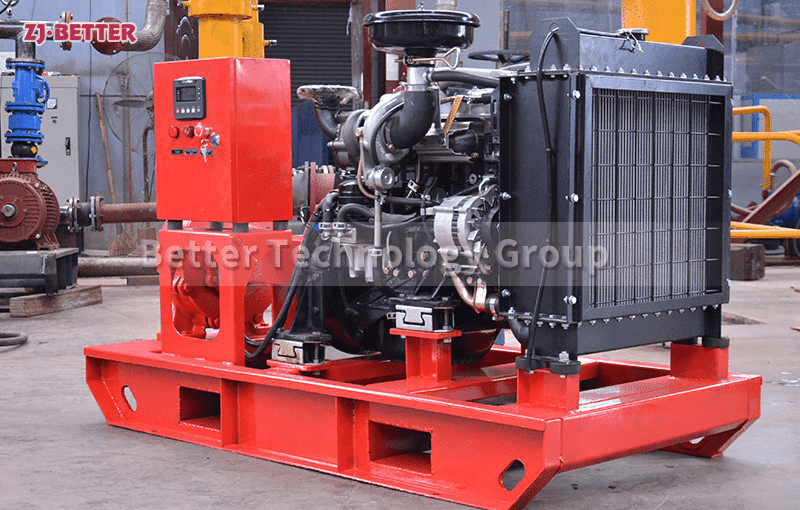

1.Reliability: Equipped with a dependable diesel engine, it operates even during power interruptions, ensuring continuous water supply capability.

2.User-friendly Operation: With automatic start-stop function, it allows for easy control of pump activation and deactivation.

3.Efficiency: Boasting an efficient water pump system, it provides ample water pressure and flow to effectively meet emergency firefighting requirements.

4.Flexibility: Designed as a mobile or portable device, it enables quick deployment and emergency use.

5.Allowable media: Potable water, chilled water, firefighting water, and other media that do not contain abrasive impurities or long fiber impurities and do not cause chemical or mechanical corrosion to the pump. Maximum allowable media temperature is 70 degrees Celsius, and maximum ambient temperature is 40 degrees Celsius.