Home » Diesel engine fire pump » Difference betwwen diesel fire pump and electric fire pump

Difference betwwen diesel fire pump and electric fire pump

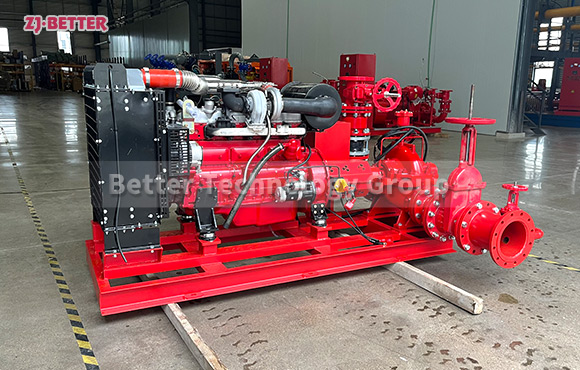

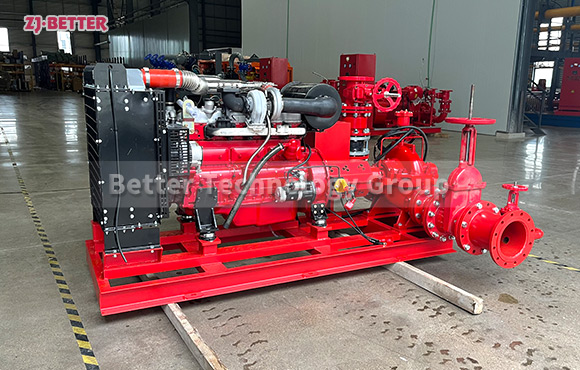

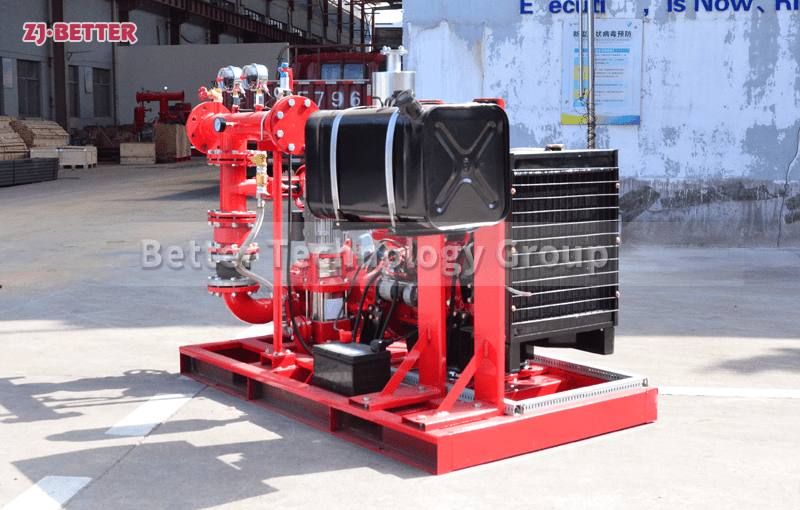

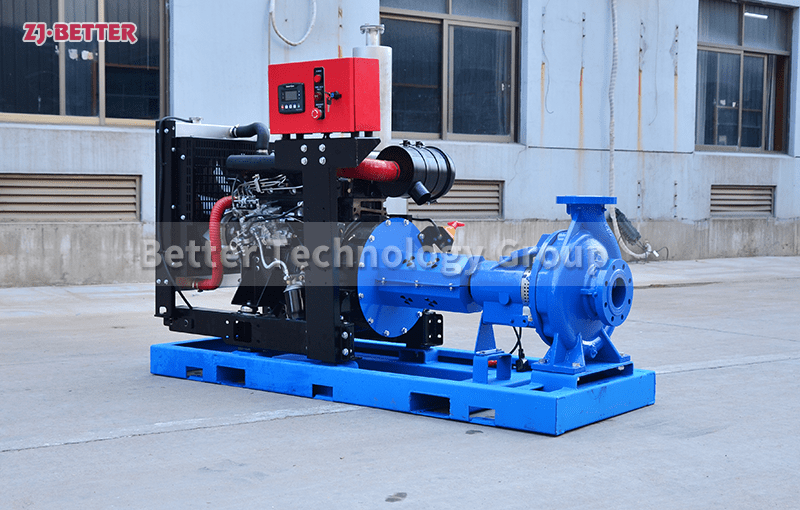

Diesel engine fire pump is suitable for unattended fire water supply system. Diesel engine fire pump is mainly used for fire hydrant fire extinguishing, automatic sprinkler fire extinguishing and other fire fighting systems in fixed fire fighting systems such as industrial and mining enterprises, engineering construction, and high-rise buildings. The clean water and chemical properties of the particles are similar to the medium of water, and can also be used in life, production and shared water supply systems and buildings, municipal water supply and drainage, docks, offshore platforms and other occasions without power supply.

Contact US

Get Price

Share:

Content

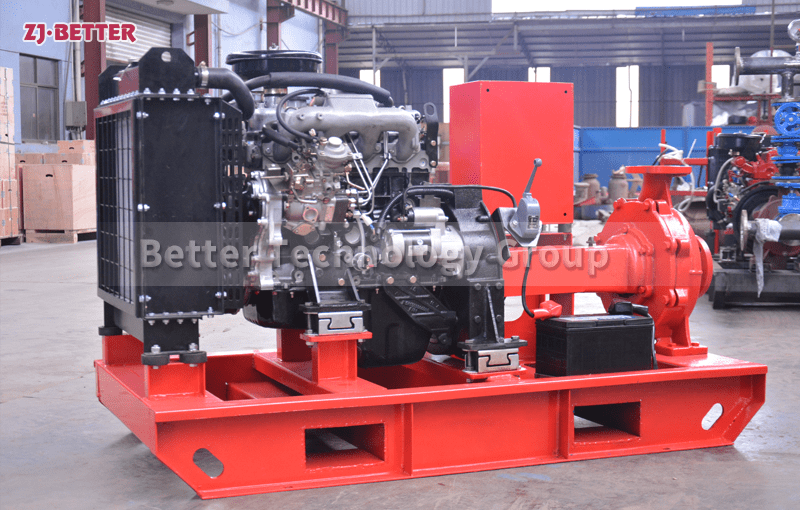

ZJBetter Technical Company’s XBC-D diesel fire pump set has the following features:

1. The fire pump unit is powered by X6135, 12V135, 4102, 4105, 6102 and other series of diesel engines. The unit also includes diesel tanks, cooling water tanks, fans, control panels (for automatic units) and other components. The diesel engine (can be equipped with a clutch) is connected with the fire pump through a highly elastic coupling to form a fire pump set

2. When it is an automatic control unit, the split diesel engine automatic control cabinet (programmable) realizes the functions of automatic start, input, automatic switching and automatic protection of the system, and can also interface with the user’s fire center or automatic fire alarm device. Realize remote monitoring.

3. In order to ensure the normal operation of the unit in an environment below 5°C, the unit can be equipped with an AC220V cooling water preheating and heating device.

4. Equipped with a constant pressure pump for constant pipe network pressure;

5. The electric pump is the main fire pump, which can be automatically started according to the fire situation;

6. Diesel engines equipped with diesel engine fire pump equipment are made of domestic or imported products. They have the characteristics of good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use and high degree of automation. It is an advanced and reliable fire fighting equipment.

Inquiry

More Diesel engine fire pump