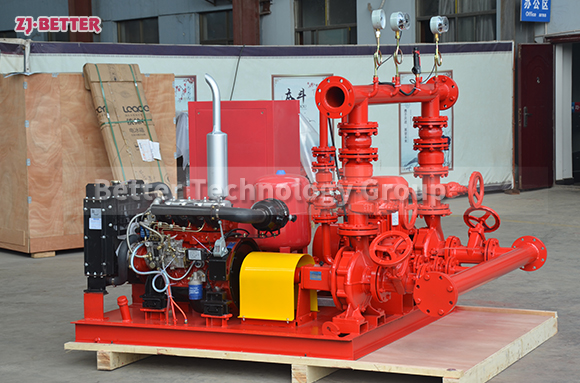

The main pump can be end suction pump, split case pump, vertical turbine pump, multi-stage pump as jockey pump, and is made of stainless steel.

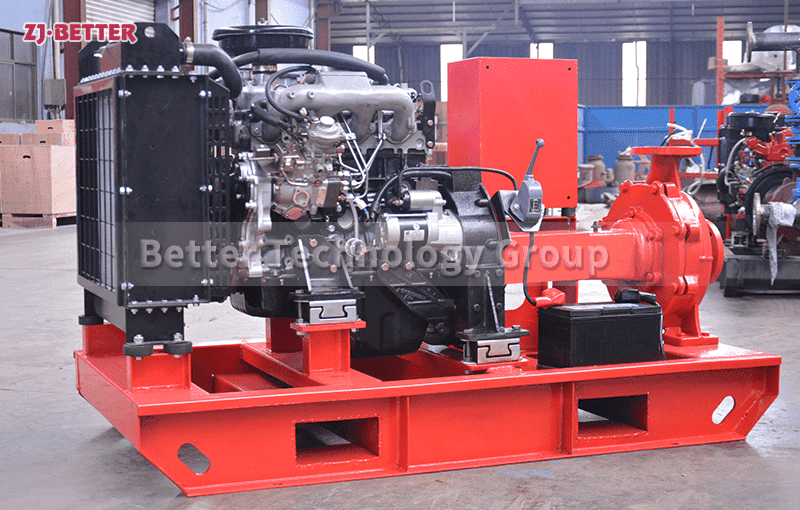

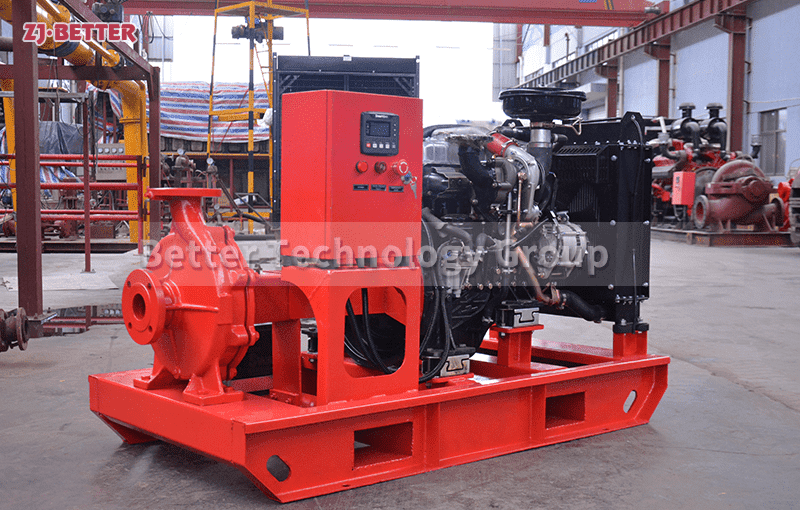

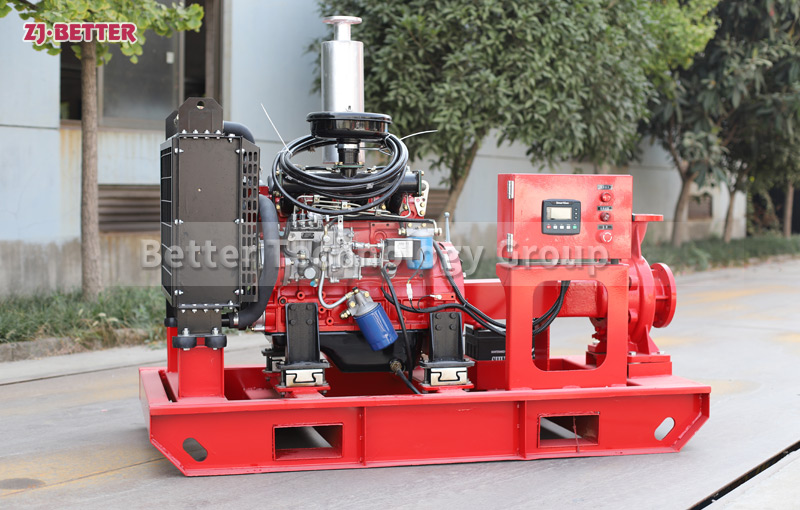

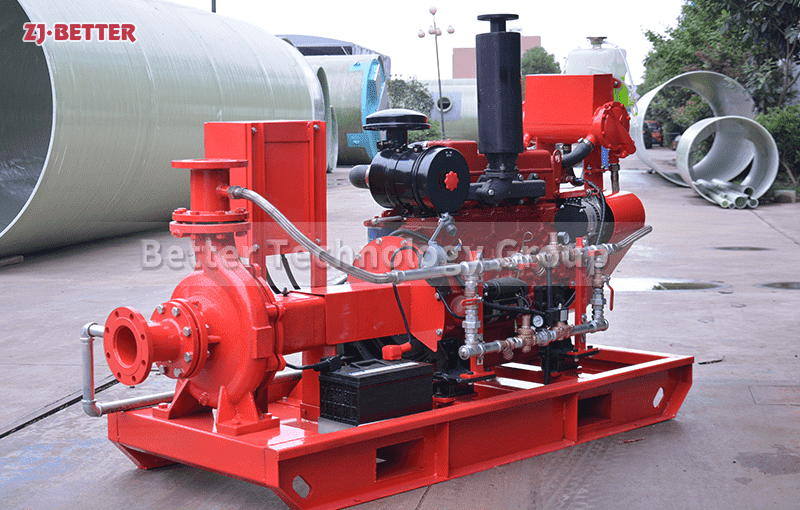

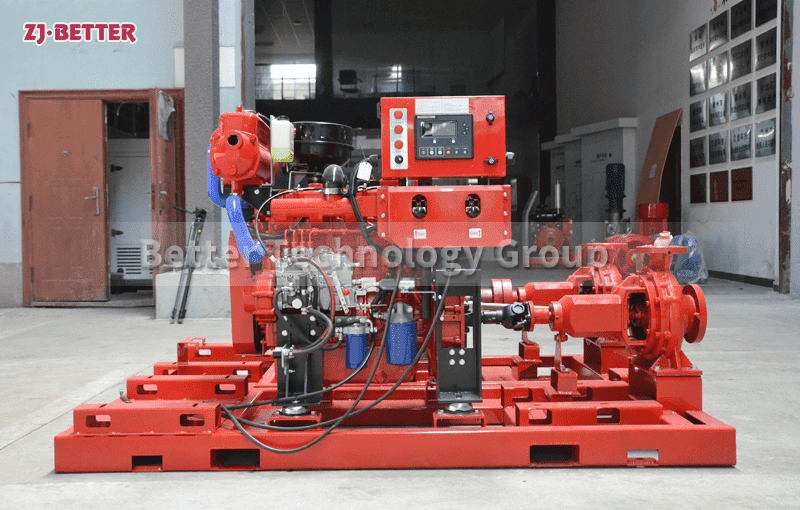

Automatic diesel pump unit: diesel water pump, jockey pump, strong steel base, radiator (heat exchanger), battery, battery wire, gate valve, check valve, flexible joint, automatic control panel.

When the pressure drops below the set value, the pump will start running according to the signal from the pressure switch.

The fire pump control panel is designed to control and monitor the operation of diesel engine and jockey pump drives, and make up pumps for manual and automatic modes, as well as to switch pump drives on/off under specific conditions. Fire Pump Series Controllers are pre-wired and tested prior to delivery.

This fire pump set can be used in fire hose and fire hose reel systems, fire sprinkler systems, fire water monitoring systems, fire alarm systems and fire hydrant systems.